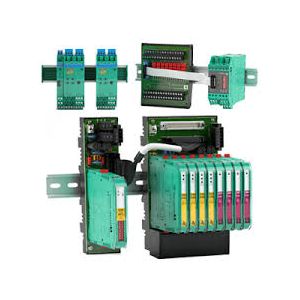

Pepperl+Fuchs Loop Powered Indicators

Overview of Pepperl Fuchs Loop Powered Indicators

A loop powered indicator, in the context of traffic control and vehicle management, is a device used to detect the presence of a vehicle within a defined area, often at intersections or entrances. These detectors play a crucial role in various applications, such as traffic signal control, toll booths, and parking facilities. Loop detectors are commonly used in combination with inductive loop technology. Let’s talk about Pepperl Fuchs loop powered indicators in more detail below.

Analysis of Loop Powered Display Units

What is a loop power display? These industrial process control displays provide digital numeric readings that require only two wires. It is powered only by a 4 to 20 mA signal and does not require any other power supply. At least four milliamps are necessary; it won't work at zero. You connect the current in series, not in parallel. Several volts are required to operate.

The display does not show 4 - 20 mA; instead, you scale it to the needed units. One display may require 0 to 400 lbs. Another may require an offset of 50 to 150 kg, and another may require -50.0 to +75.0 degrees. A current of 4 - 20 mA flows through the circuit, dropping a few volts as it passes. That's where his strength comes from. A current of 4 mA (usually a little less) does the job; no more is needed. A loop-powered display can make adding local readings to your system more accessible. You only need two low-voltage wires.

Benefits Offered by Pepperl Fuchs Signal Loop Indicators

Here are some benefits provided by Pepperl+Fuchs loop-powered instrument technology.

Efficient traffic management

Loop detectors contribute to efficient traffic flow by detecting the presence of vehicles at intersections. This information is used to optimize traffic signal timings, reducing congestion and improving overall traffic management.

Reduced traffic delays

By providing real-time information about the presence of vehicles, loop detectors help minimize unnecessary traffic delays. Traffic signal timings can be adjusted dynamically based on the actual traffic conditions.

Enhanced safety

Loop detectors play a crucial role in enhancing road safety. They ensure that traffic signals respond to the actual presence of vehicles, reducing the likelihood of accidents and improving overall safety for both drivers and pedestrians.

Adaptive traffic signal control

Current loop indicators are often used in adaptive traffic signal control systems. These systems can dynamically adjust signal timings based on current traffic conditions, leading to more efficient traffic flow.

Energy savings

Adaptive traffic signal control, facilitated by loop detectors, can lead to energy savings by reducing unnecessary idling and fuel consumption. This is beneficial for both the environment and cost savings.

Integration with Intelligent Transportation Systems (ITS)

Loop detectors can be integrated into broader Intelligent Transportation Systems, allowing for more sophisticated traffic management strategies. This may include communication with other traffic control devices and systems.

Automatic gate control

In non-traffic applications, loop detectors are often used for automatic gate control. They can detect the presence of vehicles near gates, triggering them to open or close as needed for security or access control.

Flexible applications

Loop detectors are versatile and can be used in various applications beyond traffic control, such as parking facilities, toll booths, and industrial automation.

Reliable vehicle detection

Loop detectors provide reliable vehicle detection even in challenging environmental conditions. This reliability is crucial for the accurate operation of traffic control and automation systems.

Compatibility with different vehicle types

Loop detectors are designed to detect a wide range of vehicles, from motorcycles to large trucks. This versatility makes them suitable for diverse traffic scenarios.

Practical Applications and Use Cases

Here are some practical applications and use cases for Pepperl+Fuchs loop powered devices.

Traffic signal control

One of the primary applications of loop detectors is in traffic signal control systems. Inductive loops are embedded in the road at intersections, and the loop detectors sense the presence of vehicles. The information is then used to optimize traffic signal timings, reducing congestion and improving overall traffic flow.

Vehicle actuation at intersections

Loop detectors are employed to actuate traffic signals at intersections. When a vehicle is detected waiting at a red light, the loop detector triggers the signal to change, allowing for a more efficient use of traffic signals.

Toll booth systems

In toll booth systems, loop detectors are utilized to identify the presence of vehicles at toll collection points. This information is crucial for toll collection processes and helps manage traffic through toll plazas efficiently.

Parking facility management

Loop detectors are integrated into parking facilities to monitor the occupancy of parking spaces. By detecting the presence or absence of vehicles, loop detectors contribute to effective parking management, guiding drivers to available spaces and optimizing space utilization.

Traffic data collection

Such devices can be used for collecting traffic data, including vehicle count, speed, and occupancy. This data is valuable for traffic studies, urban planning, and making informed decisions for transportation infrastructure improvements.

Railroad crossing control

In proximity to railroad crossings, loop detectors are employed to sense the presence of vehicles waiting for a train to pass. This information is crucial for activating warning signals and barriers, and ensuring safety at railroad crossings.

Industrial automation

These detectors may find applications in industrial settings for vehicle or material handling automation. For example, in warehouses or manufacturing facilities, loop detectors can be used to trigger the movement of automated guided vehicles (AGVs) or conveyors.

Smart city initiatives

In the context of smart city initiatives, loop detectors contribute to the development of intelligent transportation systems. They play a role in optimizing traffic flow, reducing congestion, and enhancing overall urban mobility.

Emergency vehicle preemption

Pepperl+Fuchs loop detectors can be integrated into emergency vehicle preemption systems, allowing emergency vehicles to trigger green lights at intersections, prioritizing their movement through traffic.

Technical Insights into Installation and Configuration

Below are some general technical insights into the installation and configuration of the Pepperl+Fuchs loop meter.

- Plan the layout and design of the inductive loop carefully. Factors such as loop shape, size, and placement are crucial for proper vehicle detection. Follow the manufacturer's guidelines for loop design, taking into account the anticipated traffic flow.

- Embed or place the loop in the roadway according to the specifications provided by Pepperl+Fuchs. Use appropriate tools and techniques to ensure the loop is securely installed and conforms to industry standards.

- Seal the loop in place using an appropriate sealant to protect it from environmental factors, including moisture. Additionally, use conduit to protect the loop wiring and make it easier to replace the loop if necessary.

- Connect the loop to the loop detector unit following the manufacturer's wiring diagram. Ensure proper polarity and insulation. Consider using shielded cables to minimize electromagnetic interference.

- Pepperl+Fuchs loop detectors allow you to adjust sensitivity. Fine-tune this setting to optimize the detector's response to different types of vehicles and environmental conditions.

- Configure the presence time settings based on the expected duration of a vehicle's presence over the loop. This setting helps prevent false positives or premature signal changes.

- Some loop detectors provide diagnostics for loop faults. Configure and monitor these settings to detect issues with the loop, such as short circuits or open circuits.

- If the loop detector supports communication protocols like RS-485 or other Fieldbus systems, configure the communication parameters according to your system requirements.

Selecting the Optimal Loop Powered Indicator for Your Specific Requirements

Here's a guide to help you select the optimal loop powered indicators by Pepperl+Fuchs.

Application requirements

Clearly define the requirements of your application. Consider the type of process variable you are monitoring (e.g., temperature, pressure, level), the desired accuracy, and the environmental conditions in which the loop-powered indicator will operate.

Type of loop powered indicator

Pepperl+Fuchs offers a range of loop-powered indicators for different applications. Identify whether you need a simple process indicator, a multifunctional indicator with advanced features, or a specialized indicator for specific processes.

Input signal compatibility

Ensure that the loop-powered indicator is compatible with the type of input signal generated by your sensor or transmitter. Common input signals include 4-20mA and voltage signals.

Signal conditioning and scaling

Check if the loop-powered indicator provides signal conditioning features such as scaling. This is important to ensure that the displayed values correspond accurately to the measured process variable.

Display type and readability

Consider the type of display that suits your application. Pepperl+Fuchs loop-powered indicators may have LED or LCDs. Assess the readability of the display, especially in challenging environmental conditions.

Housing and environmental protection

Evaluate the environmental conditions in which the loop-powered indicator will operate. Choose a model with a suitable housing material and environmental protection rating (e.g., IP65 or IP67) to ensure durability and reliability.

Mounting options

Determine the mounting requirements of your application. Pepperl+Fuchs loop-powered indicators may offer various mounting options, including panel mounting or pipe mounting. Choose the one that fits your installation needs.

Explosion protection

If your application is in a hazardous or explosive environment, ensure that the loop-powered indicator has the necessary explosion protection certifications (e.g., ATEX or IECEx).