Pepperl+Fuchs WCS - PGV - PMI - PXV Positioning

IN STOCK!!!

- art. 191136

- UL approvalcULus Listed, General Purpose, Class 2

- Power Source/Analog output: 0 V ... 10 V/4 mA ... 20 mA

- Measuring range: 0 ... 120 mm

- M12 (4-pin)

- Resolution: 0.125 mm

- SIL 3 (EN 61508)

- Category 4 PL e (EN ISO 13849)

- PROFINET interface

- PROFIsafe interface

- Safe, non-contact positioning on Data Matrix code tape

- Traverse distance up to 100 km

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

Non-contact positioning on Data Matrix code tape

Mechanically rugged: no wearing parts, long operating life

maintenance-free

- Analog output 0 V ... 10 V/4 mA ... 20 mA

- Measuring range 0 ... 104 mm

Analog output, load-dependent voltage or current

Parameterisable measuring range

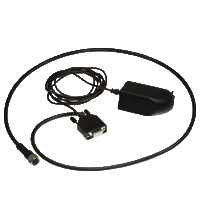

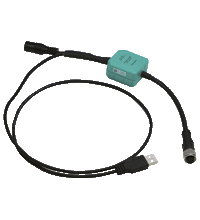

WCS interface module

- RS 485 interface

- Non-contact, absolute position encoder

- Automatic detection of dirt accumulation

- RS 485 interface

- Non-contact, absolute position encoder

- Automatic detection of dirt accumulation

- Freely positionable

- Simple installation

- Simple operating software

- Robust and insensitive to ambient interference

- Field mountable

- High chemical resistance

- Low weight

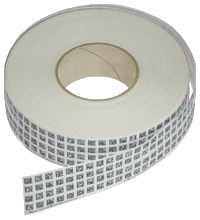

- Self-adhesive mounting

- High temperature resistance

- High mechanical stability

- High chemical resistance

- Low weight

- Self-adhesive mounting

- High temperature resistance

- High mechanical stability

- High chemical resistance

- Low weight

- Self-adhesive mounting

- High temperature resistance

- High mechanical stability

- High chemical resistance

- Low weight

- Self-adhesive mounting

- High temperature resistance

- High mechanical stability

- Power supply for 95 - 230 V AC

- Power supply for 95 - 230 V AC

- For SSI interface

- For PROFIBUS DP

- For CANopen

- For PROFINET

- For EtherNet/IP

- For SSI interface

- For PROFIBUS DP

- For CANopen

- For PROFINET

- For EtherNet/IP

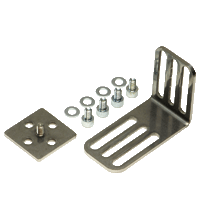

- For 25 mm code tapes

- Can be used for PCV80..., PCV100..., and PCV130... readers

- Includes 2 x eddingВ® 3000 permanent markers

- Extension cable 0.8 m in scope of delivery

- Power supply for 95 - 230 V AC

- For RS485

| Inside diameter | 76 mm |

| Material | polyester laminate |

| Operating temperature | -40 ... 100 °C (-40 ... 212 °F) |

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- CANopen interface

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- CANopen interface

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- PROFINET interface

- Integrated switch

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- PROFINET interface

- Integrated switch

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- Integrated switch

- EtherNet/IP

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 10 km, in X and Y direction

- PROFIBUS interface

- RS 485 interface

- Non-contact positioning on Data Matrix code tape

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- Travel ranges up to 524 m

- RS 485 interface

- Non-contact positioning on Data Matrix code tape

- Travel ranges up to 10 km, in X and Y direction

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

- RS 485 interface

- Non-contact positioning on Data Matrix code tape

- Travel ranges up to 10 km, in X and Y direction

- Mechanically rugged: no wearing parts, long operating life, maintenance-free

- High resolution and precise positioning, especially for facilities with curves and switch points as well as inclines and declines.

Pepperl+Fuchs offers non-contact sensors and industrial sensing systems for all these applications. The range of Pepperl+Fuchs positioning systems is presented in a wide range. Let's take a closer look at Pepperl+Fuchs positioning systems.

Benefits and features of Pepperl+Fuchs Positioning Systems

Let's take a look at the features and benefits of Pepperl+Fuchs positioning systems.

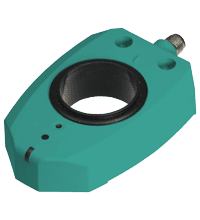

Inductive positioning systems

PMI's inductive positioning technology combines the ruggedness of a linear positioning sensor with the accuracy of position and angle measurement of a positioning system. Pepperl+Fuchs' patented technology provides very accurate data.

Main advantages of linear position systems:

- durability (non-contact, maintenance-free technology, and high environmental protection);

- variety of options: from compact designs for machine tools (measuring length 14 mm) to designs for heavy equipment (measuring length 960 mm);

- high noise immunity;

- measurement and switching in one device.

Distance sensors

Pepperl+Fuchs offers high-speed, reliable, and durable rangefinders. This category includes sensors based on unique pulse measurement technology (PRT).

The main advantage of such devices is the low cost of installation and improvement of the quality of the entire application due to the range of rangefinders, their insensitivity to interference, as well as the breadth of built-in interfaces.

Position guided vision (PGV)

Pepperl+Fuchs PGV is a pioneer in a range of tracking and positioning control systems based on a data matrix. Thanks to the main component - the latest 2D camera - PGV is not only able to send vehicles along the desired coded or colored track, but it also provides a complete solution for maneuvering, and stopping vehicles. The absolute coding system controls media movement with millimeter precision.

Advantages:

- detects colored tape even on a highly reflective surface;

- resistance to extraneous light;

- smooth navigation on a damaged or dirty feed;

- small size;

- ease of installation and launch;

- compatible with most industrial protocols.

Position coding system WCS

The automation of material handling plants requires information on the position of road trucks or material handling equipment with millimeter accuracy. With the Pepperl+Fuchs WCS, reliable and proven, precise positioning becomes a reality. For positioning, two elements are sufficient - a reading head and a code rail.

Advantages:

- absolute measuring system;

- no supporting positions;

- variable distance - up to 325 m;

- contactless way;

- resolution = 0.8 mm;

- suitable for curved paths;

- there is zero voltage protection;

- speed - up to 12 m/s;

- ease of maintenance.

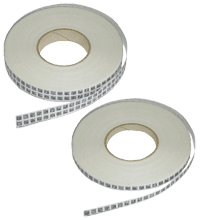

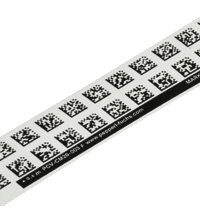

PCV positioning system

The data matrix positioning system from Pepperl+Fuchs uses individual matrix codes (labels) placed next to each other as a strip of two-dimensional codes serving as information carriers. The PCV reader head, equipped with a camera with the latest 2D code detection technology, transmits data, which is then decoded and output as an exact position in X and Y coordinates.

Advantages:

- positioning along 2 axes;

- absence of moving parts guarantees mechanical strength;

- long service life due to the absence of laser diodes;

- insensitivity to dirt and damage to the code strip;

- sequential strip code laying;

- the narrowest possible code band;

- a small reading field provides the smallest curve radius, as well as slopes and drops;

- event markers for generating control signals;

- parameterization of the camera using a PC or code cards.

Precise positioning PHA

Designed specifically for precise positioning in high bay warehouses, Pepperl+Fuchs PHA detects existing rack holes, and structures and determines their position and deviations from the location target. General disturbances such as dirt, extraneous light, or material wear are not a problem for PHA.

The main benefits of PHA:

- maximum reliability regardless of warehouse lighting or application environment;

- efficient use of storage due to high monitoring accuracy;

- thanks to reliable positioning, less raw material is required, even with wear or material deterioration.

Electronic cam controller PAX

PAX Pepperl+Fuchs cam switch controllers are used wherever control signals depending on the position of the mechanism. With the innovative PAX device, the process has become much easier. The system functions without wear and tear and maintenance, the PMI angle sensor transmits the absolute value to the PAX controller via a computer using USB.

Advantages:

- possibility to set interface parameters, individual switching windows, switching points, or switching ramps in the electronic cam controller;

- the software is integrated into PAX and activated when connected to a PC;

- up to 12 switch outputs, 250 mA each, two 2.5 A outputs, and six analog outputs;

- all data is stored on the built-in Micro SD card;

- reliable and insensitive to environmental interference;

Applications and Industries where Pepperl+Fuchs Positioning Systems are Commonly Used

Pepperl+Fuchs positioning systems are used to accurately locate objects and play an important role in many manufacturing processes. Depending on the application, this may include determining the position of objects moving along a straight path, such as tool carts, checking angles in part-turn valve actuators, or monitoring the position of a cart on an overhead rail during warehouse and transport operations.

Technical Specifications and Details on Installation and Maintenance of Pepperl+Fuchs Positioning Systems

Positioning device systems are designed for use in harsh environments and in enterprises where there is an explosion hazard. Contact our managers, and you will get advice on technical specifications, as well as the installation and maintenance of each device presented in our catalog.