Pepperl+Fuchs Encoders

- 12 increased safety outputs (Ex e)

- Short circuit current limitation per output

- Segment Protector in Zone 1/Div. 2

- Instruments in Zone 1/Div. 1

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High power on trunk and spurs

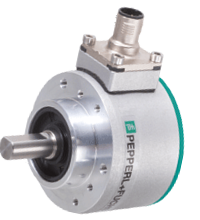

Pepperl+Fuchs Multiturn absolute encoder

- High resolution

- Precision

- Durable housing

- Wide range of applications

Pepperl Fuchs avm58n-011abr0gn-1212 Multiturn absolute encoder

- High positioning accuracy

- Data transfer rate up to 2 Mbps

- Reliable in operation

- Easy installation and configuration

Incremental rotary encoder

ENA58IL S10CA5 1213B17 ABP

- Body: AISI 303 stainless steel

- Shaft: AISI 303 stainless steel

- Bearings: Ball bearings

- Sealing: EPDM

ENI58IL S10CA5 1024UD1 RC1

- Shaft torque: Max. 1.5 Nm

- Permissible radial load: Max. 100 N

- Permissible axial load: Max. 50 N

- Impact resistance: Up to 50 g

- Vibration resistance: Up to 10 g (peak-peak)

- Clear function monitoring thanks to LED display (two-coloured)

- Easy installation and control through support functions reduce costs

- Quality assurance through comprehensive self-diagnosis, including coded disc

- Reliable function in the application thanks to internal intelligence during commissioning

Multiturn absolute encoder PSM58

Industrial standard housing Ø58 mm

PROFIBUS interface

30 Bit multiturn

PVM58I 032AGR0BN 1213

- Shaft: Ø 6 mm, stainless steel

- Maximum torque: 1 Nm

- Maximum rotation speed: 1000 rpm

- Permissible radial runout: 0.1 mm

- Permissible axial runout: 0.2 mm

- Moment of inertia: 2.8 gcm²

- max. 5000

- 140 a

- 20 a

- 1.6 E+9 at 3000 rpm

- Sturdy and compact design

- Up to 2500 ppr

- Rectangular design

- 10 V ... 30 V with short-circuit proof push-pull output

- Plastic coating

- 500 mm circumference

- Backlash-free, angle synchronous rotation transmission

- Very high torsion spring stiffness

- Material stainless steel and anodized aluminum

- Socket

- Straight

- 12-pin

- Right-rotating

- Socket

- Straight

- 12-pin

- Right-rotating

- Plug

- Straight

- 12-pin

- Right-rotating

- Socket

- Straight

- 26-pin

Incremental rotary encoder

- Guide pulley for all cable pull models

- For applications with rope exit &ge- 3В°

- Ideal for wall mounting

- Breaking ice on the measuring rope

- For bridging edges and obstacles

An encoder is a device for converting angular positions or linear movements into an analog or digital signal. In other words, an encoder is a sensor of angular or linear displacements. The principle of operation of an encoder sensor is to convert mechanical movement into electrical signals. Next, we will look at the types of Pepperl Fuchs encoders.

Pepperl Fuchs encoder catalog has three types of encoders:

- Absolute

- Incremental

- Linear

P&F Absolute Encoders are position sensors that count the number of unique digital codes per unit of disk rotation and are used to measure the main kinematic parameters of the electric drive: speed and shaft position. In other words: the main task of an absolute encoder is to read sequences of codes (or so-called states) per rotation cycle of the encoder disk.

The entire disk of an absolute encoder is divided into a certain number of sectors. These sectors are assigned certain values. An absolute encoder, when the shaft rotates, reads sector data, forming a certain individual (or absolute code), this code forms individual sequences of marks printed on the encoder disk. Signals are read using a photocell (receiving matrix).

P&F Incremental Encoders are devices for counting the number of pulses from a reference point per unit revolution of shaft rotation. They generate a serial pulse digital code containing information regarding the angle of rotation of the shaft. That is, the main task of an incremental encoder is to count single pulses per cycle equal to one revolution of the disk.

The pulses in an incremental encoder are generated by rotating the cue disk. The countdown of one revolution is determined by the starting marks. The starting marks are the reference marks on the rotating disk of the incremental encoder, which are determined by the pulse encoder immediately after being put into operation.

In the non-rotating state of an incremental encoder, the output is a logical one. At the start of rotation of the incremental encoder in any direction, first, one pin is connected to the ground, and then the other pin is connected to the ground, thus forming zero. Further, when the encoder rotates, these outputs are disconnected from the ground in turn, and a logical unit is again formed at the outputs. The cycle is repeated. Thus, a sequence of zeros and ones is formed in the incremental encoder.

Linear Encoders are used to measure the linear displacements of an object. This applies to determining its position, speed, acceleration, and other parameters. In any case, only the displacement of the linear type will be measured. Pepperl Fuchs linear encoder doesn’t suit to measure the movement of rotating objects or moving along curved paths, so you need to choose among other types of encoders.

In order to accurately read the absolute value, two tracks are read simultaneously by the head (non-contact method). After the signal from the track is read, its value (that is, information about the movement and coordinates of the object) is sent for processing by one or another automated system. Transfer can be carried out through different interfaces, depending on the installed equipment.