Pepperl+Fuchs Slot and Slot Grid Sensors

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Infrared light

- Degree of protection IP67

- cULus approval

- Sturdy aluminum housing

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Visible red light

- Degree of protection IP67

- cULus approval

- Sturdy aluminum housing

- High switching frequency

- High resolution

- Sturdy aluminum housing

- Light/dark switching

- Alignable housing

- Adjustable sensitivity

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Visible red light

- Degree of protection IP67

- cULus approval

- Diecast zinc housing, powder coated

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- High switching frequency

- High resolution

- Sturdy aluminum housing

- Light/dark switching

- Alignable housing

- Adjustable sensitivity

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Visible red light

- Degree of protection IP67

- cULus approval

- Sturdy aluminum housing

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Infrared light

- Degree of protection IP67

- cULus approval

- Diecast zinc housing, powder coated

- High switching frequency

- High resolution

- Sturdy aluminum housing

- Light/dark switching

- Alignable housing

- Adjustable sensitivity

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Visible red light

- Degree of protection IP67

- cULus approval

- Diecast zinc housing, powder coated

- Optimized for the detection of small parts

- High switching frequency

- Multiple device installation possible, no mutual interference (no cross-talk)

- Sensitivity adjuster and light/dark switch as standard features of this series

- Visible red light

- Degree of protection IP67

- cULus approval

- Diecast zinc housing, powder coated

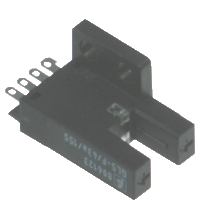

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

- Miniature design

- Optimized for the detection of small parts

- High switching frequency

- Simple and fast mounting

- Clearly visible LED functional display

Pepperl+Fuchs is a German company specializing in the development and production of industrial sensors and automation technologies. They offer a wide range of products for various industrial applications, including sensors for object detection and distance measurement. Below we will take a closer look at Pepperl+Fuchs slot and slot grid sensors.

Key Features of Pepperl+Fuchs Slot and Slot Grid Sensors

The Pepperl+Fuchs catalog contains two types of reliable safety monitoring devices. Let's look at them.

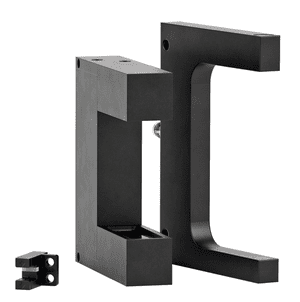

Slot sensors

Slot sensors, also known as fork sensors or U-shaped sensors, are used to detect the presence or absence of an object within a specific slot or gap in the sensor. They consist of an emitter (generates a beam of light or another type of energy) and a receiver (detects the presence or absence of the emitted energy). When an object passes through the slot, it interrupts the beam of light or energy, causing the sensor to detect the object's presence.

These sensors are commonly used in applications where you need to detect the presence or position of objects on a conveyor belt, in a packaging machine, or in other industrial automation processes.

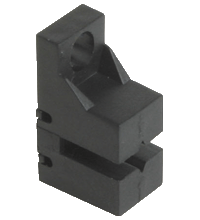

Slot grid sensors

Slot grid sensors are similar to slot sensors but have an array of slots or gaps, often arranged in a grid pattern. This grid configuration allows for more precise positioning and detection of objects. They work on the same principle as slot sensors, with multiple beams of energy being emitted and detected.

Slot grid sensors are frequently used in applications where you need to monitor and control the movement of objects in a grid or matrix layout, such as checking for the presence of products on a pallet or ensuring proper alignment on a production line.

Applications of Slot and Slot Grid Sensors

Precision detection sensors Pepperl+Fuchs Here are some common applications for Pepperl+Fuchs slot and grid sensors for industrial applications.

- Object detection and counting.

- Label detection.

- Edge detection.

- Web break detection.

- Positioning and alignment.

- Thickness measurement.

- Registration mark detection.

- Speed and RPM measurement.

- Safety applications.

- Automation and robotics.

- Packaging and sorting systems.

- Bottling and filling lines.

Technical Specifications of Pepperl+Fuchs Slot and Slot Grid Sensors

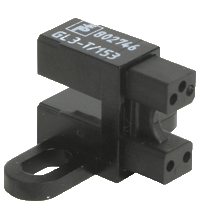

Pepperl+Fuchs industrial slot sensors have different types of light sources, such as IRED (modulated infrared light) and LED (modulated visible red light). Also, these devices have different slot widths and depths, for example in the GL10-RT/32/40a/98a model The slot width is 10 mm and the depth is 17 mm. In this case, the target size is 0.3 mm. Or, for example, model GL220-RT/32/40a/98a where the slot width is 220 mm and its depth is 60 mm with a target size of 0.5 mm. These are examples of two of the more than hundreds of industrial protection devices that Pepperl+Fuchs offers, meaning you can choose a slot or slot grid sensor for any application.

Installation and Maintenance Guidelines

The installation and maintenance of these sensors are critical to ensuring their proper functionality and longevity. Below are some general guidelines for the installation and maintenance of safety sensors.

- Sensor selection. Ensure that you have selected the appropriate type and model of slot or slot grid sensor for your specific application. Different sensors are designed for various purposes, so consult the product documentation to make the correct choice.

- Power supply. Provide the sensor with the correct power supply as specified in the product documentation. Check the voltage and current requirements of the sensor, and ensure a stable power source.

- Mounting. Follow the sensor's mounting instructions closely. Ensure that the sensor is securely and precisely positioned in the installation area. Proper alignment is essential for accurate detection.

- Distance and gap. Maintain the recommended gap distance between the sensor and the target object. Deviating from the specified gap distance can affect sensor performance.

- Environmental conditions. Consider the environmental conditions in which the sensor will operate. Some sensors may have specific temperature, humidity, or protection ratings that need to be adhered to for proper operation.

- Wiring. Use the appropriate wiring for the sensor. Ensure that the wiring is properly insulated, shielded, and protected from environmental factors like moisture, vibration, or interference. Follow color-coding and labeling standards as applicable.

- Alignment and calibration. Properly align the sensor and calibrate it according to the manufacturer's recommendations. Calibration may include setting detection thresholds or configuring sensitivity settings.

- Regular inspection. Periodically inspect the sensor to ensure it is clean, free from physical damage, and securely mounted. Ensure that the gap between the sensor and the target is maintained.

- Cleaning. Keep the sensor clean from dust, dirt, or any other contaminants that may accumulate over time. Use a suitable cleaning agent or method recommended by the manufacturer.

- Firmware/software updates. If applicable, keep the sensor's firmware or software up to date with the latest releases provided by Pepperl+Fuchs.