altivar process

- Ambient temperature: -10°C - +40°C (standard)

- Vibration: 0.5 g (peak-to-peak)

- Impact: 5 g (peak-to-peak)

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

- With heat sink

- 3 phases

- 75 kW

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

22kW, 480V, 30hp, 3ph, EMC, IP21

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

| Device short name | ATV212 |

| Product destination | Asynchronous motors |

| Product specific application | Pumps and fans in HVAC |

| Assembly style | With heat sink |

| Network number of phases | 3 phases |

Frequency converters are devices designed to convert alternating current (voltage) of one frequency into alternating current (voltage) of another frequency. The output frequency in modern converters can vary over a wide range and be either higher or lower than the main frequency.

Next, we will take a closer look at the line of frequency converters Schneider Electric Altivar 212 Process.

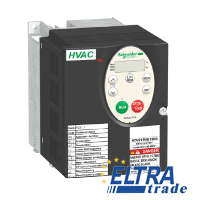

Schneider Electric Altivar 212 VFD

Schneider Electric Altivar 212 is used for three-phase asynchronous motors powered by 220V (200) or 380V (480) and power from 0.75 to 75 kW. This series replaces the discontinued ATV21 series inverters.

Altivar 212 are dedicated frequency converters used in modern heating, ventilation, and air conditioning (HVAC) systems in residential and public buildings. Using the Altivar ATV 212 significantly improves the maintenance of building systems by providing significant energy savings, simplifying networks (by eliminating valves and flow control valves), reducing noise levels, flexibility, and ease of installation of equipment.

Altivar ATV 212 drives are equipped with a built-in terminal with 7-segment displays. It is designed to identify and define active command channels (run command and speed reference).

The display allows you to:

- Direct access to the last five parameters changed.

- Identification of factory-set parameters as a list in the menu.

- User configuration support. Altivar 212 drives offer a quick setup function using a "Quick Menu" that includes 10 basic parameters (acceleration, deceleration, motor parameters, etc.).

Thanks to the Altivar 212, energy savings of up to 70% are achieved.

The main types:

atv212hd, atv212hu, atv212wd, atv212wu

Altivar 212 Characteristics

And now let's pay attention to the main characteristics of the Schneider Electric Ativar 212 VFD:

● Altivar 212 is designed to control 3-phase asynchronous. electric motors with power from 0.75 kW to 75 kW with mains supply:

- 200-240 V, 3 phases, from 0.75 kW to 30 kW, IP 21;

- 380-480 V, 3-phase, from 0.75 kW to 75 kW, IP 21;

- 380-480V, 3 phase, 0.75kW to 75kW, 12/IP 55 UL type.

● Adjustment range: 1:50.

● Maximum torque: 110% for 60 s.

● Built-in EMC filter, category C1 - C3, depending on the model.

● Integrated communications: Modbus, METASYS N2®, APOGEE FLN P1®, and BACnet®. Optional: LonWorks Optional: LonWorks.

● Conforms to international standards and certifications: UL, CSA, C-Tick, and NOM.

● Anti-harmonic technology achieves THDI < 30% without additional filters.

Advantages of the Schneider Altivar 212

Next, let's find out what are the main advantages of the Schneider Altivar 212.

Alarm system

- Monitoring of energy consumption.

- Fault detection for prompt intervention: belt break, pump running dry, phase failure, power failure, etc.

- Preventive maintenance to reduce costs and optimize equipment: alarm, operating time, etc.

- Connection to the building management system, using built-in protocols.

Easy installation, configuration, and operation

- A large number of online and configuration tools are offered to enable installation, configuration, and commissioning quickly and efficiently (Remote HMI in 8 languages, Multi-Loader, Bluetooth, and SoMove Mobile).

- Compact size.

- Ease of maintenance.

Special focus on protection

- Ensures reliable operation and protection of equipment.

- Versatile “special purpose” functions specially designed for the use of the inverter in buildings and structures (fire mode, valve control, mechanical protection function, etc.)

- Built-in EMC filter, anti-harmonic technology (THDI ˜ 30%).

Applications ATV 212

Now we will consider in what areas Schneider altivar 212 can be used.

Ventilation

- Less noise interference (pneumatic-hydraulic noise, motor noise, etc.).

- Transmission component break detection.

- Smoke extraction: forced start with fault suppression.

- Automatic restart.

- Allows valve control.

Heating and air conditioning

- Optimization of control when cleaning liquids.

- Using a PID controller (temperature, flow, pressure, etc.).

- Cost management for better energy management.

- Suppression of mechanical resonance.

Pumps

- Underload/overload detection, pump running dry.

- Configuration for multiple motors.

- Limited operating time at low speed.

- Standby/on function.

- Surge suppression to extend equipment life.

Altivar 212 VFD Installation Manual

According to the operating conditions, the installation of the frequency converter requires the following precautions and the use of appropriate accessories:

- The inverter is mounted in a vertical position ± 10°.

- Secure the base surface of the frequency converter with M5 screws with a spring washer.

- Do not install the inverter near heating elements.

- Leave enough space so that the air needed to cool the device can circulate from the bottom to the top.

- Free space in front of the device: >10 mm.

It is recommended to use spring washers for all screws.

Special recommendations for cabinet installation

- To ensure the necessary air circulation in the frequency converter:

- Install ventilation grilles.

- Make sure there is adequate ventilation. Otherwise, install a more powerful filter fan.

- Openings and/or fans must provide at least as much airflow as the frequency converter fans.

- Use special filters with UL type 12/IP54 protection.

- Remove the protective film (cover) from the top of the frequency converter.

Installation in a dust- and moisture-proof metal cabinet

Pay attention to the risk of condensation. If there is a risk of condensation, keep the frequency converter running when the motor is not running or install thermostat-controlled heating elements. Failure to follow this instruction may result in equipment damage.

Installing the frequency converter in dust and moisture-proof cabinet is necessary under certain operating conditions: in the presence of dust, corrosive gases, high humidity with the risk of condensation and dripping, liquid on the surface, etc. The maximum temperature inside the cabinet must not exceed 50 °C.

When installing the drive in a UL Type 12 or IP54 cabinet, follow these ventilation guidelines:

- Ensure minimum free space.

- If necessary, install a fan inside the cabinet to avoid hot spots inside the inverter and to evenly distribute heat over the surface of the cabinet for convective cooling.

If you want to get complete information about this line of frequency converters as well as a detailed installation diagram, then you can read the Schneider Altivar 212 manual.