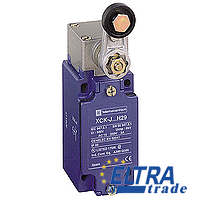

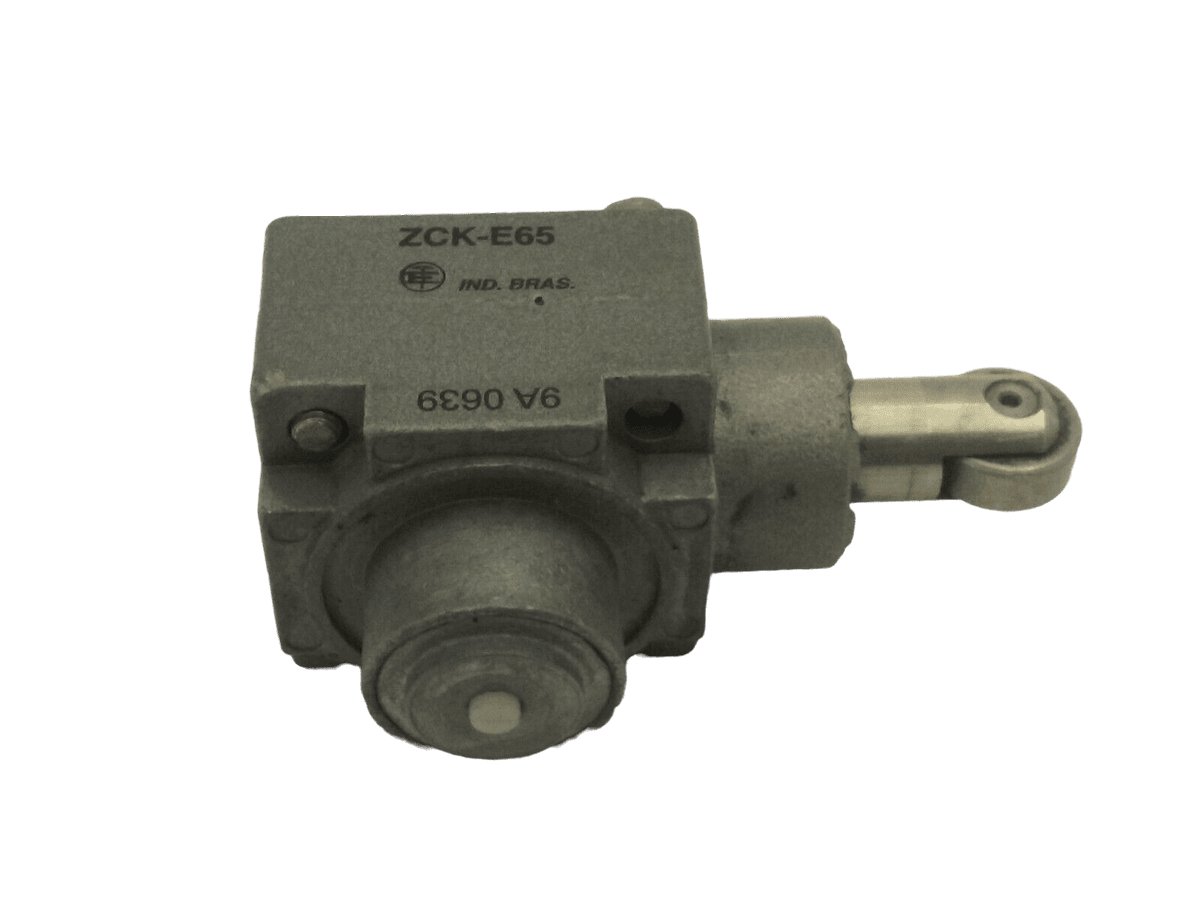

Schneider Electric OsiSense XC

xckj10511 schneider

- Number of poles: 2

- Minimum torque for positive opening: 0.5 Nm

- Minimum torque for disconnection: 0.25 Nm

- Maximum actuation speed: 1.5 m/s

IN STOCK!!!

Telemecanique Limit switche XC Standard

Pg11, 1NC+1 NO, snap action, metal end plunger, 2P

- XCKL

- thermoplastic roller lever

- 1NC+1 NO

- snap action

- 1/2NPT

- M30

- 6..150cy/min

- Sn 10mm

- 2m cable

| Product or component type | Limit switch |

| Device short name | XCKJ |

| Sensor design | Form A conforming to CENELEC EN 50041 |

| Body type | Fixed |

| Head type | Rotary head |

| Product or component type | Limit switch |

| Device short name | XCKJ |

| Sensor design | - |

| Body type | Fixed |

| Head type | Rotary head |

| Product or component type | Limit switch |

| Device short name | XCKJ |

| Sensor design | - |

| Body type | Plug-in body |

| Head type | Rotary head |

| Product or component type | Limit switch |

| Device short name | XCKJ |

| Sensor design | Form B conforming to CENELEC EN 50041 |

| Body type | Fixed |

| Head type | Plunger head |

| Product or component type | Wireless limit switch |

| Device short name | XCKW |

| Body type | Fixed |

| Head type | Plunger head |

| Body material | Plastic |

| Product or component type | Wireless limit switch |

| Device short name | XCKW |

| Body type | Fixed |

| Head type | Rotary head |

| Body material | Plastic |

| Product or component type | Wireless pack |

| Device short name | XCKW |

| Kit composition | 1 receiver 2 relays output 1 wireless limit switch with spring return roller plunger |

| Product weight | 0.41 kg |

| Product or component type | Wireless pack |

| Device short name | XCKW |

| Kit composition | 1 wireless limit switch with spring return roller lever 1 receiver 2 relays output |

| Product weight | 0.41 kg |

| Product or component type | Limit switch |

| Device short name | XCMD |

| Sensor design | Miniature |

| Body type | Plug-in body |

| Head type | M12 plunger head |

OsiSense XC from Schneider Electric is a series of sensors designed for industrial applications. These sensors are used to detect the presence or absence of objects, measure distances or monitor certain conditions in various industrial processes. Let's find out more about the Schneider Electric OsiSense XC.

Features and Specifications of Schneider Electric OsiSense XС

Let's take a look at some of the general features and specifications of the OsiSense XC.

The main categories includes:

- OsiSense XCKJ Industrial range

- OsiSense XCK Classic range

- OsiSense XC Compact range

- OsiSense XCM Miniature range

Sensor types

- The OsiSense XC range includes different types of sensors for various industrial applications

- OsiSence inductive proximity sensors. These devices are used to detect the presence or absence of metal objects.

- Capacitive proximity sensors. Sensors are used to detect a wide range of materials, including non-metallic objects.

- Ultrasonic sensors. These sensors are used for distance measurement, object detection, and level measurement.

- Photoelectric sensors. These devices are used for object detection, counting, and positioning using light beams.

- Pressure Sensors. These sensors are used to measure pressure in gases or liquids.

Sensitivity range

Each type of sensor in the OsiSense XC range has specific sensitivity ranges that determine the distance or proximity at which they can detect objects or measure distances. The sensitivity range may vary depending on the specific model and type of sensor.

Output types

OsiSense XC sensors offer various types of outputs for interfacing with control systems or PLCs. General output options include.

- Transistor outputs NPN (normally open/normally closed) or PNP (normally open/normally closed) for proximity switches.

- Analog output options for pressure transmitters.

- Digital outputs such as NPN, PNP, or relay outputs for photoelectric sensors.

Connection options

OsiSense XC sensors typically provide connection options that are compatible with industry-standard connection methods. This includes pre-wired cables or connectors making it easy to integrate sensors into existing systems.

Applications of Schneider Electric OsiSense XC

Schneider OsiSense XC sensors are used in a variety of industrial processes requiring reliable and accurate sensors. Here are some common applications where they are used.

- Presence detection.

- Counting and sorting objects.

- Distance measurement and positioning.

- Liquid level monitoring.

- Machine safety.

- Material detection.

- Monitoring and control of pressure.

- Automation and robotics.

It is important to note that the applications of OsiSense XC sensors are not limited to the examples above. The versatility of the range of sensors allows them to be customized and adapted to meet specific industrial process measurement needs in a variety of sectors including manufacturing, automotive, food and beverage, packaging, and more.

Installation and Maintenance of Schneider OsiSense XC

Installation and maintenance of Schneider Electric OsiSense XC sensors require special attention to ensure proper functionality and durability. Here are some general guidelines to help you.

Device installation.

- Review the OsiSense XC standard datasheet, including the installation guide and user manual provided by Schneider Electric. These documents contain specific instructions and recommendations for the installation process. Then choose a suitable place to mount the sensor.

- Provide the necessary power to the sensor according to the manufacturer's specifications. Check the voltage and current requirements and make sure they match the power source available in your system.

- Follow the connection instructions provided in the documentation to ensure a correct and secure connection. Use appropriate cables, connectors, and terminal blocks as recommended by Schneider Electric.

- After installation, perform a thorough test and check to make sure the sensor is working properly. Check the correct detection, accuracy, and response according to the specified parameters.

Device maintenance.

- Perform regular visual inspections of the OsiSense XC sensors for any signs of damage, wear, or loose connections. Inspect the sensor housing, wiring, and mounting to make sure everything is in good condition.

- Keep the sensor clean by removing dirt, dust, or debris that may accumulate on the surface of the sensor. Gently wipe the transducer with a clean, soft cloth or brush. Avoid using harsh chemicals or abrasive materials that could damage the sensor.

- Check wiring connections periodically to make sure they are secure and tight. Loose connections can cause the sensor to malfunction.

- If necessary, calibrate or adjust the parameters of the OsiSense XC sensor according to the manufacturer's instructions. This may include recalibrating the sensing distance, sensitivity, or other adjustable parameters.

- Follow the recommended maintenance intervals provided by Schneider Electric. These intervals may include lubrication, component replacement, or a system check.