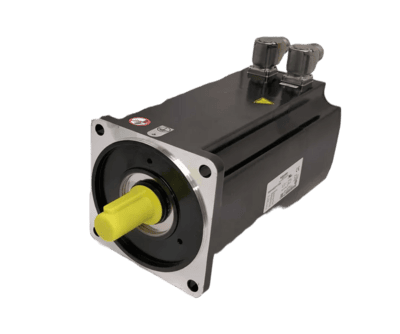

Schneider Electric Servo motor BMH

The Schneider Electric BMH series servomotor is a highly efficient and reliable drive. The company engineers have designed it for industrial solutions. Such devices offer many benefits which makes them ideal for tasks that require fast and precise positioning. The main features of BMH include low inertia, a wide range of power, and the ability to work under high-load conditions.

In addition, Schneider Electric automation solutions support various communication interfaces, which allows you to integrate them into complex control systems. Also, the devices are compatible with a wide range of other manufacturer drives and controllers, which simplifies their implementation into the infrastructure you already have. Moreover, built-in overload protection and the ability to operate in a wide temperature range ensure durability and reliability in difficult operating conditions.

Benefits of Using Schneider Electric Servo Motors

Such precision motion control solutions have many advantages that make them popular in various industries. Let's find out what advantages the company can offer you.

High accuracy and repeatability

Each Schneider servo motor provides high-accuracy control of position, speed, and torque, which is especially important for applications that require precise positioning and repeatable movements.

Wide speed range

These devices are capable of operating over a wide speed range, allowing them to be used in a wide variety of industrial processes, from slow and precise to fast and powerful.

High torque

BMH can deliver high torque in a small package, making them ideal for compact installations with limited space.

Energy efficiency

These servo motors are highly energy efficient, helping to reduce energy costs and reduce the environmental impact.

Reliability and durability

The manufacturer uses high-quality materials and advanced manufacturing techniques, which ensures the durability and reliability of its servo motors, even under intensive use.

Integration with automation systems

The drives are easily integrated with Schneider Electric automation systems and other platforms, simplifying their implementation and management.

Compact design

Thanks to their compact design, these servo motors can be easily integrated into existing systems without the need for significant changes to the equipment design.

Flexible configurations

BMH servo motors support various communication protocols and can be adapted to operate in various configurations, making them versatile for use in various industries.

Applications of the Schneider Electric BMH Servo Motors

Schneider Electric industrial automation solutions are top-rated and can be used in many areas. Below we will consider in more detail which ones.

Industrial robots. BMH servo motors are used in robotics to provide precise and fast control of the movement of manipulators and working tools.

CNC machines. Servo motor for CNC machinery provides high positioning accuracy and smooth operation of spindles and axes.

Packaging lines. In the packaging industry, BMH motors are used to synchronize the movements of conveyors, cutters, and other mechanisms, ensuring stable and fast operation of the equipment.

Robotics. Due to the high dynamics and accuracy, due to its fast and precise movement, a servo motor for robotics is an ideal solution.

Material processing. In CNC machines and other processing systems, BMH motors provide smooth and precise movement of working tools, which is critical for processing quality.

Textile equipment. BMH servo motors are used in the textile industry to control the movement of weaving and knitting machines, ensuring the accuracy and stability of the process.

Injection molding machines. In the production of plastic products, BMH motors are used to control the movement of molds and material feed, which ensures precise dosing and product quality.

Conveyor systems. In automated warehouse and logistics systems, BMH servo motors control the movement of conveyors, elevators, and sorting mechanisms, improving the efficiency and speed of cargo handling.

Food industry. In the production and packaging of food products, BMH servo motors are used to control dosing machines, cutters, and packaging machines, ensuring the accuracy and hygiene of the process.

Medical equipment. BMH motors are used in medical devices such as surgical robots and diagnostic equipment, where high precision and reliability are required.

Automation of assembly lines. In the automotive and electronics industries, BMH servo motors provide precise and synchronized movement of assembly mechanisms, which helps to increase productivity and assembly quality.

Why Choose Schneider Electric for Your Servo Motor Needs?

Schneider Electric’s choice for high-performance servo motors is based on its reputation as a leader in innovation and quality in industrial automation. The company offers solutions that combine advanced technology and years of experience. BMH Schneider servo motors are known for their high precision, reliability, and durability, making them an ideal choice for mission-critical applications in a variety of industries, including mechanical engineering, robotics, and packaging.

Schneider Electric also offers complete solutions that include not only the servo motors themselves, but also control systems, software, and integration with other automation components. This allows customers to get a single solution for the entire motion control system, ensuring compatibility and simplifying the implementation process. The company actively supports its customers at all stages, from design to maintenance, which contributes to the successful implementation of projects.