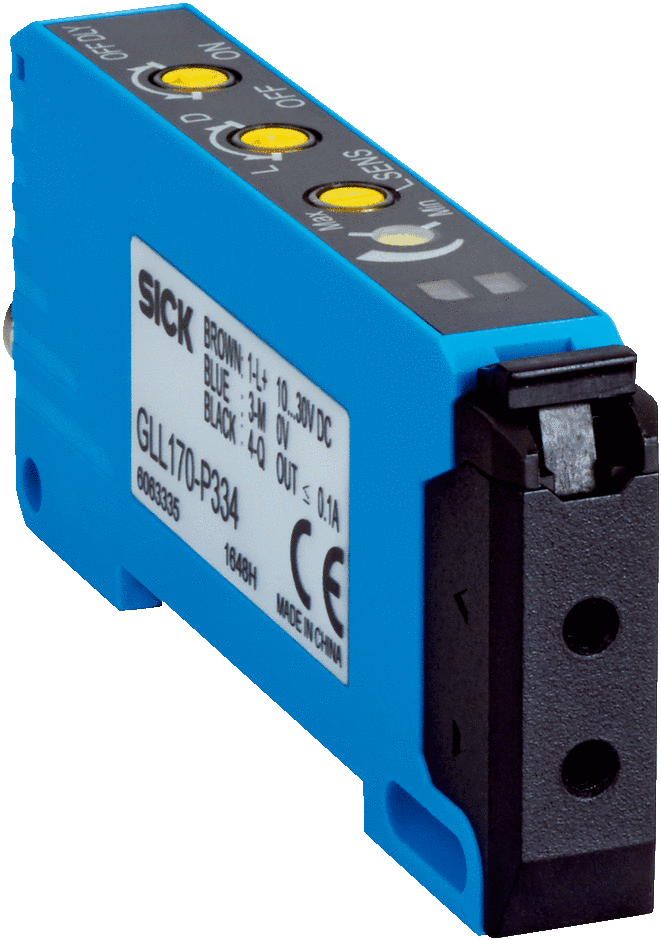

Sick Photoelectric sensors

IN STOCK!!!

- art. 1041422

- Series W12-3

- Sensing range: 20 mm ... 600 mm

IN STOCK!!!

Photoelectric sensors in a standard housing

IN STOCK!!!

Photoelectric Sensors

- Weight: 0.174 Kg

- Volume: 728.0 cm³

- Dimensions: 8.000 * 7.000 * 13.000

- Metal housing that has been IP 69k tested

- Switch selectable PNP or NPN output

- Switch selectable Light or Dark operating mode

Hybrid photoelectric sensors H18 Sure Sense

- Laser protection class 1 or 2

- Autocollimation optics

- Rugged sensors for industrial use

- Laser protection class 1 or 2

- Autocollimation optics

- Rugged sensors for industrial use

- Laser protection class 1 or 2

- Autocollimation optics

- Rugged sensors for industrial use

- Laser protection class 1 or 2

- Autocollimation optics

- Rugged sensors for industrial use

- Classification: EX II 2G Ex ia op is IIC T4 according to Directive 94/9/EC (ATEX)

- Corresponds to Category 2G

- Output type: EN 60947-5-6 (NAMUR)

- Classification: EX II 2G Ex ia op is IIC T4 according to Directive 94/9/EC (ATEX)

- Corresponds to Category 2G

- Output type: EN 60947-5-6 (NAMUR)

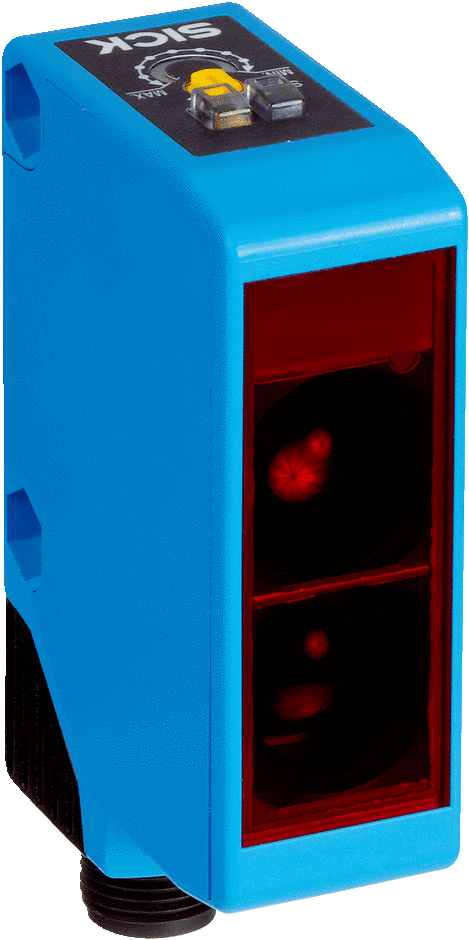

Compact photoelectric sensors W250-2

Compact photoelectric sensors W260

- Marking: EX II 2G Ex ia op is IIC T4, according to Directive 94/9/EC (ATEX)

- Rated category 2G for explosive environments

- Output type: EN 60947-5-6 (NAMUR)

- Marking: EX II 2G Ex ia op is IIC T4, according to Directive 94/9/EC (ATEX)

- Rated category 2G for explosive environments

- Output type: EN 60947-5-6 (NAMUR)

- Laser protection class 1 or 2

- Large sensing range and high levels of operating reserve

- Rugged sensors for industrial use

- Long sensing range with high operating reserve

- Metal housing that has been IP 69k tested

- Switch selectable PNP or NPN output

- Long sensing range with high operating reserve

- Metal housing that has been IP 69k tested

- Switch selectable PNP or NPN output

- Long sensing range with high operating reserve

- Metal housing that has been IP 69k tested

- Switch selectable PNP or NPN output

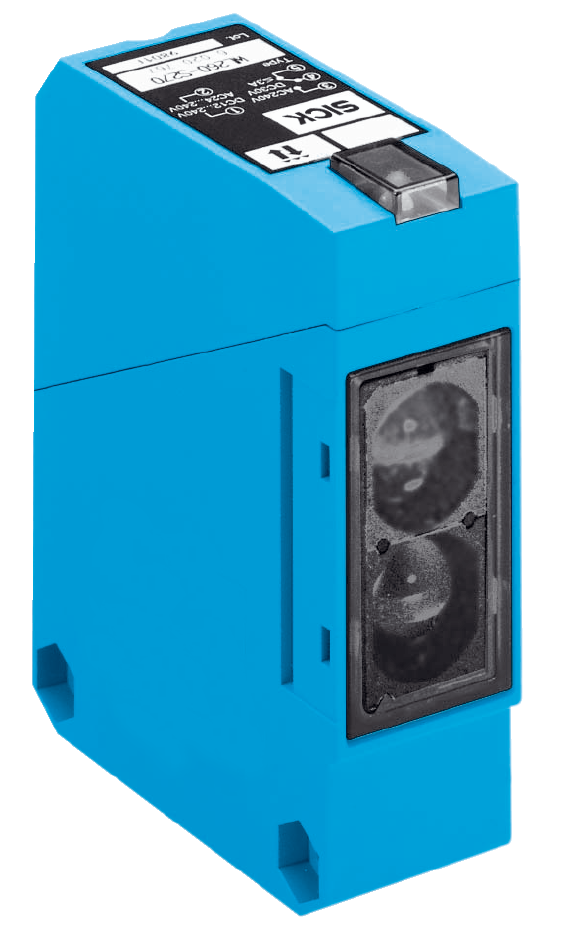

- High operating reserve at a long range

- Switch selectable PNP or NPN output and light/dark switching

- Versions with DC voltage (10...30V) or universal AC/DC voltage (12 … 240 V DC / 24 … 240 V AC)

- High operating reserve at a long range

- Switch selectable PNP or NPN output and light/dark switching

- Versions with DC voltage (10...30V) or universal AC/DC voltage (12 … 240 V DC / 24 … 240 V AC)

- High operating reserve at a long range

- Switch selectable PNP or NPN output and light/dark switching

- Versions with DC voltage (10...30V) or universal AC/DC voltage (12 … 240 V DC / 24 … 240 V AC)

- High operating reserve at a long range

- Switch selectable PNP or NPN output and light/dark switching

- Versions with DC voltage (10...30V) or universal AC/DC voltage (12 … 240 V DC / 24 … 240 V AC)

Switch selectable PNP or NPN output and light/dark switching

Versions with DC voltage (10...30V) or universal AC/DC voltage (12 … 240 V DC / 24 … 240 V AC)

A photoelectric sensor is a compact electronic device that evaluates the parameters of an object that falls into the coverage area by processing light radiation of different ranges. They are classified into several types depending on the design and other features, but the principle of operation of this equipment is the same in each case. Today we will talk more about Sick photoelectric sensors.

What is a Sick Photoelectric Sensor?

The photo sensor Sick is an optical sensor comprising a light source, a light receiver, and a signal output and control circuit. They can detect the presence of objects and sometimes the state of the surface.

When the emitted light is interrupted by an object in the immediate vicinity, the light receiver detects this change and switches the sensor output on or off. Some proximity sensors can even determine the distance to an object.

How Does a Sick Photoelectric Sensor Work?

The photoelectric sensor Sick works on the principle of measuring the intensity of the light beam emitted by the transmitter and incident on the photosensitive element of the receiver. Depending on the purpose of the sensor, different types of light are used, from which the beam is modulated.

Infrared light is often chosen, which is invisible to the human eye. Thanks to this, object detection can be carried out in a way that does not attract attention. Still, this solution also has its drawbacks, as anyone who has installed, for example, a sensor in the gate, which should prevent them from closing when a vehicle is standing in them, could see.

It is because of this that when performing installation work, laser pointers are often used as an additional accessory to facilitate the relative positioning of the transmitter and receiver.

Advantages of Sick Photoelectric Sensors

Sik photoelectric sensors have a lot of advantages, which we will discuss below.

- Detection of objects of various textures and colors

- IP69K shockproof stainless steel housing suitable for use on equipment that is cleaned with Ecolab-certified products.

- Possibility to select the switching logic "Light/Dark" via cable connection.

- Easy and convenient mounting thanks to M3 threaded mounting holes.

- Superior optical performance and reliable performance thanks to Sick ASIC technology.

- Easy to install and adjust thanks to the handy potentiometer and good

- visible status LEDs.

You can always find the device you need in the Sick photoelectric sensor catalogue provided by Eltra Trade.

Applications of Sick Photoelectric Sensors

Photoelectric sensors are widely used in many industries. Some industries are listed below.

- Agricultural machinery. Plant height detection in the agricultural industry for more efficient chemical spraying.

- Automatic systems. Industrial and private car washes. Level control of soap and wax in automatic car washes. Capacitive sensors are able to detect the level of liquid in plastic tanks, which allows operators to make timely replacements.

- Food, drinks, and tobacco products. The bottling process is under severe conditions. Production of fruit juices and jams. Detection of food in automatic feeders. Capacitive sensors detect the presence of pellets in the feeders. Detection of heads of cattle in meat processing plants. Production and packaging of dairy and sausage products.

- Production. Detection of paper on reels. Ultrasonic sensors control the presence of paper on the reel, for its timely replacement by the operator.

- Control of belt vibrations in grinders. Production of wood, plastic, rubber, and metalworking. Detection of objects coming out of furnaces. Special high-temperature sensors should be used in these production areas. Hand protection in automated areas and assembly lines. Monitoring the filling level of silo pits when collecting grain pdf

- Application in grinding machines. Control of the presence of operators in vehicles.

- Glass. Application in glass cutting machines. Detection of the presence of a glass sheet prior to the start of the cutting operation.

- Metal and steel. Hand protection in presses. If the sensor detects the operator's hand in an unacceptable area, a signal is given to immediately stop the equipment.

- Rock processing. Processing of marble and granite. Determination of the presence of marble or granite blanks before starting processing.

- Package. Detection of goods inside the box. Capacitive sensors detect the presence of goods inside the box through the walls of the box.

- Rubber and plastic. Hand protection in injection molding machines.

- Solar panels. Production of solar panels. During production, it is necessary to identify the location or presence of a solar panel. Capacitive sensors should be used.

- Textile industry. Hand protection in textile machinery.

- Trucks and other vehicles. Stabilizer expansion control in hydraulic valves.

- Commodity warehouses. Access control to storage areas. Detection of moving metal objects in warehouses. Used in loaders.

- Recycling. Waste level control.

Choosing the Right Sick Photoelectric Sensor for Your Needs

When choosing photoelectric sensors, one should rely on the object of measurement and proceed from its properties. Since, for example, shiny or transparent objects (made of plastic, glass, metal) can be easily detected by one type of optical photo sensor, and for sensors of another type, such objects will be a big problem and it will not be possible to achieve stable detection of such products.

And if you want to know the Sick photoelectric sensor price, you can always check the product catalog on the Eltra Trade website.

Maintenance Tips for Sick Photoelectric Sensors

For the entire production system to work properly, every tool and part must be well maintained. Perform regular system checks and complete the following tasks for all parts.

- The sensor must be fixed to all installation locations provided by the manufacturer.

- Use brackets to prevent excessive vibration.

- Do not leave cables and connectors dangling freely, fix everything superfluous.

- If possible, install protective covers and protect them by any means from mechanical influences, as well as from dust settling.

- Timely clean the sensor and reflectors.

The best way to make your sensors work well is to involve all users in their care. Also remember to periodically hire a professional for a full review, as they will point out any important features that need improvement.

Troubleshooting Common Issues with Sick Photoelectric Sensors

There is a list of problems that may occur during the operation of photoelectric sensors. Let's find out how to fix the most common troubles.

- Clean your device. If this is the first time and the sensor is registering false positives, start by cleaning the entire sensor. Clean the output beam, receiver, and, if applicable, reflector. It is best to use a soft, clean, dry cloth and, if the sensor is visibly dirty, a non-abrasive, non-corrosive cleaner. After thoroughly cleaning the sensor parts, test the sensor to make sure it works.

- Re-align the pieces. If they still don't work, carefully align the entire system. This requires a rope and two people (exception: the diffuse scanner works at such a small distance that its displacement must be visually noticeable). stretch the string between them. If the photo eyes are misaligned, align them along the thread, first in the left-right direction, and then in the up-down direction. Once they are roughly aligned, continue to make minor adjustments to the emitter just until the transducer is working properly.

- Contact your dealer. If all else fails, contact the dealer who sold you the transducers - they can tell you about other more advanced procedures you can try, including changing the gain control and narrowing the beam.

If you want to get more detailed information about the device then you can check out the Sick photoelectric sensor manual.

Product Line:

- W12 Photoelectric sensors

- W24 Long-range sensor

- W27 Photoelectric Sensors

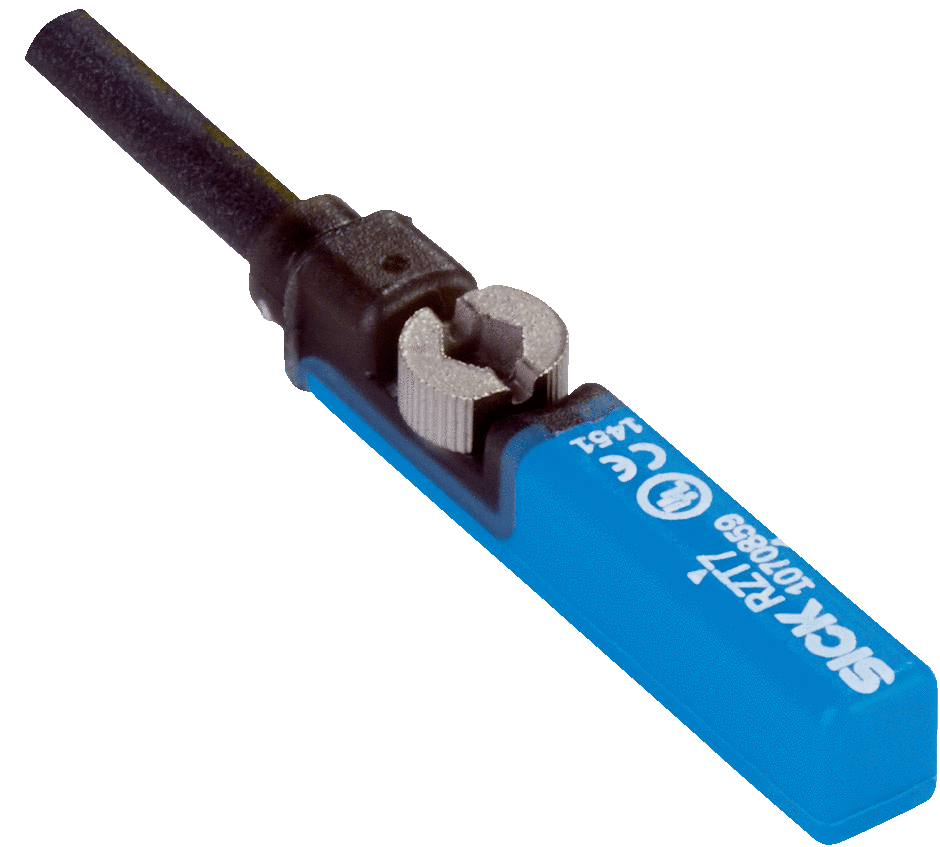

- Fiber-optic sensors