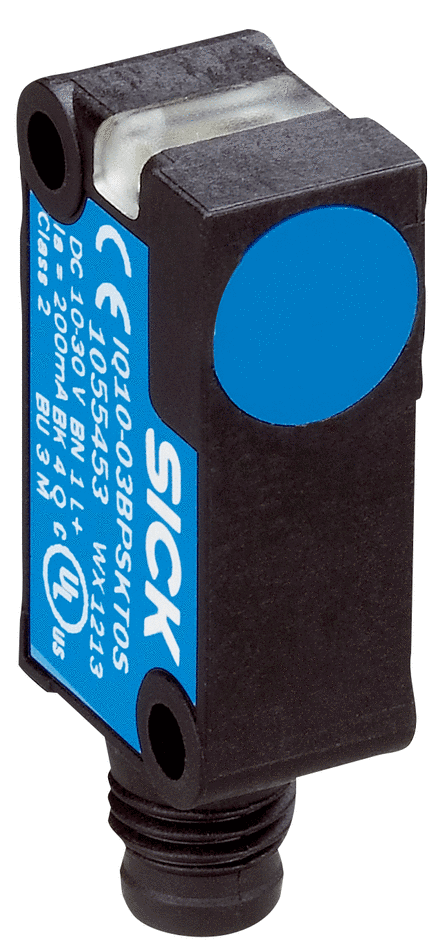

Sick Proximity sensors

IN STOCK!!!

Inductive proximity sensors

- Size: M18

- Enclosure rating: IP67

- Operating temperature: -25...+75° C

IN STOCK!!!

Magnetic field sensor

- Operating temperature: -25 °C ... 75 °C

- Switching frequency: 5,000 Hz

- Supply voltage: 10 V DC ... 30 V DC

- M30 - cylindrical housing

- Adjustable sensing range from 2 to 16 mm shielded and 4 to 25 mm unshielded

- Best-in-class electromagnetic compatibility

- PNP or NPN output versions are available

- Operating distance up to 10 mm

- High electromagnetic immunity

- Operating distance of up to 4 mm

- High switching frequency

- Short-circuit protection (pulsed)

- Size M30

- Output signal proportional to distance

- Triple operating distance

- Size M30

- Output signal proportional to distance

- Triple operating distance

- Size M12

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Size M18

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Size M30

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Size M30

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Size M30

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Size M30

- IP 67 enclosure rating

- Operating temperature from -25° C to +75° C

- Pressure resistant up to 500 bar

- Expected service life of up to 1 million pressure cycles

- Expanded temperature range of up to 100 °C

- Pressure resistant up to 500 bar

- Expected service life of up to 1 million pressure cycles

- Expanded temperature range of up to 100 °C

- Pressure resistant up to 500 bar

- Expected service life of up to 1 million pressure cycles

- Sensing range of 1.5 mm flush

- Pressure resistant up to 500 bar

- Expected service life of up to 1 million pressure cycles

- Sensing range of 1.5 mm flush

- Pressure resistant up to 500 bar

- Expected service life of up to 1 million pressure cycles

- Sensing range of 3 mm flush

- Tough VISTALTM housing

- SICK-ASIC technology

- 270° status display with extra-bright LED

- Tough VISTALTM housing

- SICK-ASIC technology

- 270° status display with extra-bright LED

- Tough VISTALTM housing

- SICK-ASIC technology

- 270° status display with extra-bright LED

- Tough VISTALTM housing

- SICK-ASIC technology

- 270° status display with extra-bright LED

- Tough VISTALTM housing

- SICK-ASIC technology

- 270° status display with extra-bright LED

- Flat, compact design

- Long sensing distance up to 1.5 mm

- Easily visible indication LEDs

- Detection of magnets

- Operating distances up to 90 mm or more based on the magnet strength

- High switching frequency

Proximity sensors are electronic devices that register the presence or absence of an object in the sensor's coverage area. This is a fairly wide class of sensors, the operation of which is based on various physical phenomena or principles of operation: capacitive, and inductive. Let's take a closer look at Sick proximity sensors.

What are Sick Proximity Sensors?

The proximity sensor is an electronic sensor that can detect the presence of objects in their immediate vicinity without any physical contact. To detect objects, a proximity sensor emits or emits a beam of electromagnetic radiation, typically in the form of infrared light, and measures the reflection to determine the proximity of an object or distance from the sensor.

Proximity sensors are commonly used in industry, from manufacturing and food processing to processing. They are also used in vehicles to detect the proximity of other vehicles to their own vehicle, as well as for parking assistance functions.

There are many types of proximity sensors and they use different methods for sensing. For example, the Sick capacitive proximity sensor is more suitable for plastic and organic targets, while the Sick inductive proximity sensor can only detect metal targets.

What Does a Proximity Sensor Do?

The proximity sensor Sick detects an object without touching it and therefore does not cause abrasion or damage to the object. Devices such as limit switches detect an object by touching it, but proximity switches detect the presence of an object electrically without touching it.

Proximity sensors use solid-state outputs, so there are no contacts to affect life. Unlike optical detection methods, proximity sensors are suitable for use in places where water or oil is used. Detection occurs with virtually no exposure to dirt, oil, or water on the object to be detected.

Proximity sensors provide a fast response compared to switches that require physical contact. Also, such devices can be used in the temperature range from -40 to 200 C.

Sick proximity sensors detect physical changes in an object, so they are almost unaffected by the object's surface color. Unlike switches, which rely on physical contact, proximity sensors are affected by ambient temperature, surrounding objects, and other proximity switches.

Choosing the Right Sick Proximity Sensor for Your Needs

All applications have specific needs, but in general, the following steps will help you select the right Sick sensor for your application.

- What sensing distance is required? The detection distance is the distance between the sensor tip and the object to be detected. In the selection guide and in the technical data table for each sensor family, regardless of manufacturer, the sensing distances are indicated.

- How much space is available to install the sensor? Have you ever tried round probe or short body versions but couldn't fit them? Rectangular sensors can meet your needs. The same technology as the standard round proximity sensor is housed in a rectangular housing. This technology includes sensing distance, electrical protection, and switching frequencies similar to round sensors.

- Need a shielded or unshielded sensor? Shielded and unshielded sensors are also referred to as embedded and non-embedded. Unshielded sensors provide longer sensing distances, while shielded sensors allow flush mounting.

- Sensor placement. Consider placement in the environment. Will the sensor be underwater, in a high-temperature environment, constantly splashed with oil, etc.? This will determine the type of sensor you can use.

Maintenance Tips for Sick Proximity Sensors

Let's take a look at tips for maintaining Sic sensors.

- Place the sensors in ideal conditions. When placing sensors for long-term outdoor measurements, solar sensors should be placed where they will not be in the shadow of surrounding objects such as trees or power poles. Avoid locations where the sensors may be exposed to drops or splashes, or where birds may perch.

- Proper sensor installation. Each sensor manual contains mounting recommendations, and Apogee has developed specific mounting brackets for a variety of applications. Solar sensors should be mounted level to ensure accurate and consistent measurements and sensor cables should be mounted to point to true north in the northern hemisphere or true south in the southern hemisphere to minimize azimuth error.

- Check wiring connections. Make sure your wiring is secure and properly connected. Intermittent and often annoying problems can occur when the wiring is not making good contact with the controller/datalogger being used.

- Clean the sensors. Blocking the optical path between the target and the detector can result in low readings. Dust and dirt can be removed from the sensor disk using a non-abrasive cloth or cotton swab moistened with deionized water or a window cleaner. Calcium deposits from irrigation water leave a thin white film on the surface that can be removed with a dilute acid such as vinegar. Infrared radiometers may have spider/insect and/or wasp nests in the opening leading to the filter. If spiders/insects are a problem, repellent should be applied around the entrance to the aperture (not on the filter).

- Know what you are measuring. Familiarity with sensor specifications, operation, and measurements will help you recognize errors before data stored for days or weeks becomes unreliable and unusable.

Troubleshooting Common Issues with Sick Proximity Sensors

Sometimes unforeseen situations can occur with sensors. In such cases, you can take a few simple steps to fix the problems.

- Define the problem. Try to identify the problem due to which the proximity sensor stopped working on its own. This way you may be able to quickly fix the problem.

- Clean the sensor. Another possible problem could be sensor contamination. Try to completely clean the device and perhaps the problem will be solved.

- Re-align all parts. There is a possibility that some parts of your device are located incorrectly. In order to solve this problem, you need to align the photo eyes with a thread from top to bottom and then from left to right.

- Check inputs. Make sure all inputs are receiving electrical current.

- Contact a dealer. If none of the above helped you then contact your dealer for assistance.

If you want to know the Sick proximity sensor price or see the detailed characteristics of each of the available devices, you can do it on the Eltra Trade website. And if you have any questions, our managers will be happy to provide you with advice.