SMC Air cylinders

IN STOCK!

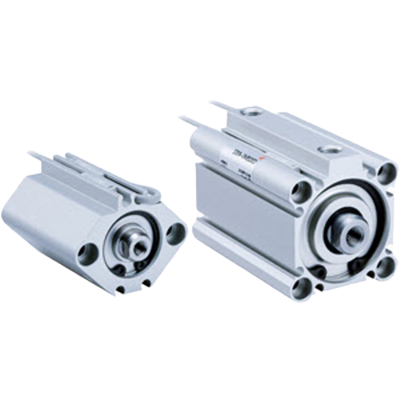

SMC CQ2B20-20DM belongs to CQ2 SMC cylinders.

Double-acting and standard design with internal rod thread.

- C(D)75

- Air Cylinder

- Double Acting

- Single Rod

- Standard

- C(D)76

- Air Cylinder

- Double Acting

- Single Rod Configurator

- C(D)76

- Air Cylinder

- Double Acting

- Single Rod Configurator

- C(D)85

- ISO 6432 Standard Cylinder

- Double Acting

- Single Rod Configurator

- C(D)85-S/T

- ISO 6432 Cylinder

- Single Acting

- Single Rod Configurator

- C95S(D)

- ISO Cylinder

- Double Acting

- Single Rod

- Large Bore Configurator

- C95S(D)

- ISO Cylinder

- Double Acting

- Single Rod

- Large Bore Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D) 125

- ISO Cylinder

- Double Acting

- Single/Double Rod Configurator

- C96S(D) 125

- ISO Cylinder

- Double Acting

- Single/Double Rod Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96S(D)

- ISO 15552 Cylinder

- Double Acting

- Single/Double Rod w/Air Cushion and Bumper Cushion Configurator

- C96Y(D)

- ISO 15552 Cylinder

- Smooth Cylinder

- Double Acting

- Single Rod configurator

- C(D)75

- Air Cylinder

- Double Acting

- Single Rod

- Standard

- C(D)75

- Air Cylinder

- Double Acting

- Single Rod

- Standard

- C(D)75

- Air Cylinder

- Double Acting

- Single Rod

- Standard

- C(D)75

- Air Cylinder

- Double Acting

- Single Rod

- Standard

| Standard stroke lengths | up to 300 mm |

| Weight | 63020 lb (ca. 28,585 kg) |

- C(D)85

- ISO 6432 Standard Cylinder

- Double Acting

- Single Rod Configurator

- ISO 6432 Standard Cylinder

- Double Acting

- Single Rod Configurator

Pneumatic cylinders are actively used today to perform all kinds of operations with compressed air (inlet or outlet in various elements of the circuit breaker, outlet, stopping or limiting its supply at a certain point in time, inlet into an arc extinguisher, etc.). Today we will take a closer look at the SMC air cylinders catalog.

Types of SMC Air Cylinders

The main types of SMC Air Cylinders are:

- Clamp cylinders

- Compact air cylinders

- Compact air cylinders ISO

- Compact air cylinders with guide rod

- Free mount cylinders

- Guide cylinders

- Hydraulic cylinders

- ISO air cylinders

- Rodless cylinders

- Stainless steel cylinders

- Standard air cylinders

- Table cylinders

Depending on the design, SMC cylinders are divided into.

- Miniature SMC cylinders. This includes screw-in, ultra-small equipment with the ability to install position sensors.

- The standard series includes a wide range of products. Models with an increased resource, combined damping, for use in the food industry, high-speed travel, with the possibility of mounting position sensors, and others are presented.

- SMC special pneumatic cylinders include a series with air-operated stoppers, swivel clamping cylinders, guided type, smooth acceleration and deceleration, high side impact resistance, and more.

Let's take a closer look at the SMC cylinder catalog.

Miniature cylinders

- Needle Cylinder CJ1

- Screw-in air cylinder CJP

- Pneumatic cylinder for panel mounting CJPB

Standard cylinders

- Pneumatic cylinder according to ISO/VDMA C85

- Pneumatic cylinder standard C76

- Pneumatic cylinder according to ISO/VDMA C95

- Pneumatic cylinder according to ISO/VDMA CP95

- Guides for ISO cylinders GUM GUL

- Pneumatic cylinder according to ISO C92

- Pneumatic cylinder CS1

- Pneumatic cylinder compact, collapsible CG1

- Stainless steel pneumatic cylinder CG5

Compact cylinders

- Compact cylinder diameter 12-25 mm CQS

- Compact cylinder standard diameter 12-100mm ECQ2

- Compact cylinder standard diameter 125-200 mm CQ2

- Air-damped compact cylinder RQ

- Compact Cylinder for CDU/CDUK Universal Mounting

- Compact cylinder with CQM guides

- Compact Cylinder Guided MGP

- Dual force cylinder with anti-rotation mechanism MGZ

- Cylinder compact, low friction MQQ

- Cylinder compact, low friction MQM

Special cylinders

- Cylinder with precision lock C92LA

- Cylinder with positioner C92P

- Cylinder with smooth acceleration and deceleration REC

- Rodless cylinder with smooth acceleration and deceleration at the end of the stroke REA

- Guided Cylinder MGG » Flat Cylinder MU

- Swivel clamping cylinder MK2

- Pneumatic shaker XT316

Features of SMC Air Cylinders

All SMC pneumatic equipment is powered by compressed air. With the help of pneumatic cylinders installed in the system, the energy of compressed air is transformed into mechanical energy. With the help of compressed air pressure, the piston moves inside the hollow sleeve, dividing the inner cavity into the rod and piston parts. The connection of the rod with the object occurs through a sealing cuff, according to the same scheme, the force is transferred from the piston. Its value directly depends on the piston diameter and air pressure.

Due to the installation of rubber rings or special dampers, the impact load at the end of the working stroke is reduced. According to the number of end positions, pneumatic cylinders are divided into two and many positions. The design of the latter allows you to fix the rod at the given points, in addition to only in the extended or retracted position.

Applications of SMC Air Cylinders

The use of a pneumatic cylinder depends on the application in which it is used. The main function of SMC air cylinders is to generate motion and force from air pressure through the influx of compressed gas, the specific role of the pneumatic cylinder will depend on the application of the product.

The force and motion generated by pneumatic cylinders can be used in mechanisms such as clamping, pushing, blocking, and lifting. In factories, they are used to repeatedly pick up and place objects in a machine or equipment. In piping systems, they are used in service valves.

In the manufacturing industry, pneumatic cylinders are often used to open valves, doors, lift things onto conveyor belts, and lift heavy objects.

In the automotive industry, pneumatic cylinders play a different role. They are used in cars and trucks for suspension and brakes.

Benefits of Using SMC Air Cylinders

One of the strengths of SMC pneumatic cylinders is their unique piston ring design, which minimizes friction and thus improves system performance. With a minimum area at the point of contact, which does not increase even with reciprocating motion, it is possible to ensure maximum tightness.

The design creates favorable conditions for lubrication, it is evenly distributed over the surface, which ensures smooth movement at low speeds. The lubricant incorporated at the time of manufacture of the pneumatic cylinder is designed for the entire period of its operation and does not require replacement.

By choosing SMC air cylinders you also get a number of other benefits.

- Suitable for use in harsh industrial environments with a high degree of pollution.

- An oil sealing ring is installed, which provides an increased degree of tightness.

- Aimple installation due to the high accuracy of the connecting dimensions.

- Resistance to shock loads is achieved with the help of a thickened wall of the sleeve.

- Ease of maintenance is achieved through the use of a replaceable sealing ring.

- High corrosion resistance is achieved through the use of stainless steel or carbon steel with a high carbon content, chrome-plated as a structural material.

If you are interested in buying this equipment, then you can always check out the SMC cylinders catalogue, on the Eltra Trade website.

Maintenance and Care Tips for SMC Air Cylinders

Knowing the basics of repairing pneumatic cylinders will reduce your team's downtime and cut costs. Below are some things to keep in mind regarding the maintenance and repair of pneumatic cylinders.

- Always turn off the power and bleed any remaining air before starting repairs and maintenance. Pneumatic systems have compressed air which can be very dangerous, and this danger increases when the system is still connected to the power supply.

- Always inspect the cylinder, tube, and stem seal for rust or damage as these areas are most susceptible to wear. If there is a lot of rust or damage, you may need to replace the entire cylinder and its fasteners.

- Check that there is no dust left on the outer surface of the air cylinder or the mounting bracket.

- Don't forget to lubricate! Always check that all necessary cylinder components are properly lubricated and use grease packs if not enough. These components require proper lubrication to operate at full capacity:

- Piston outer surface

- piston rod surface

- Piston seal groove

- Piston seal inner and outer surface

- stem seal

- Stem seal groove on stem cap

- Pipe gaskets

- The inner surface of the pipe

If you want to buy equipment from SMC, feel free to contact Eltra Trade. We are the official SMC air cylinder distributor and guarantee you high-quality cylinders and the best service.