SMC Parts in Stock

IN STOCK!

5-port pilot operated solenoid valve

IN STOCK!!!

Pneumatic regulator

- Body Size: 40

- Port: 04 (1/2)

- Option: Standard

IN STOCK!

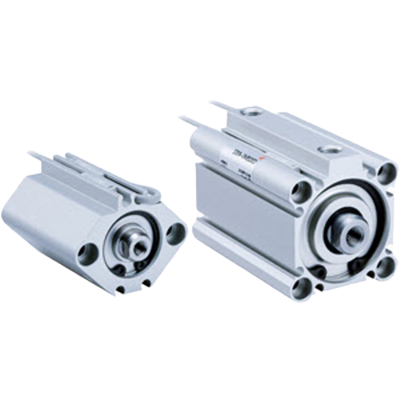

SMC CQ2B20-20DM belongs to CQ2 SMC cylinders.

Double-acting and standard design with internal rod thread.

d a90v

- Type: reed switch

- Load voltage: 24 V DC

- Load current: 50 mA

- Dimensions: 12.7 x 6.3 x 4.5 mm

IN STOCK!!!

smc dz73 sensor

- Type: non-contact

- Control method: magnetic field

- Type of contacts: NO (normally open)

- Angle of operation: 180 degrees

IN STOCK!!!

Valves

- Max operating temperature: 60 ° C

- Voltage - 220 V

- Power consumption: 2 W

- Sold in packages of 10; price is per piece

- Port Size: 1/4

- Sealant: S (With Thread Sealant)

- Applicable Tube: 6

Fitting

- Port Size: 1/4

- Sealant: S (With Thread Sealant)

- Applicable Tube: 8

- Sold in packages of 10; price is per piece

- Release Button: Round Type

- Sealant: S (With Thread Sealant)

- Applicable Tube: 6

IN STOCK!!!

Fitting

- Port Size: 1/4

- Applicable Tube: 6

- Sealant: S (With Thread Sealant)

In stock!!!

- Polyurethane, 5/8, clear

- Price for 1 pc

In stock!!!

- Polyurethane, 5/8, 1 tube, green

- Price for 1 pc

In stock!!!

- Size: 8/5

- Color: Red (opaque)

- Price for 1 pc

IN STOCK!!!

Solenoid Valve

- Voltage: 24V DC

- Body: O (For manifold)

- Pressure: standard type 0.7 MPa

IN STOCK!!!

VQZ200 Valve, SOL 3-PORT

IN STOCK!!!

Hybrid regulator

- Max effective area: 670 mm

- Power supply: 24 V DC

- Signal voltage: 1 to 5 V DC

SMC Corporation was founded in Tokyo, Japan and today has over 20,800 talented employees in 83 countries. SMC entered the pneumatics market in 1959 and has since evolved with customer needs to create a comprehensive range of automation equipment. 12,000 basic components and more than 700,000 variants provide the best competitive advantage. Despite having been listed on the Tokyo Stock Exchange since 1989, its greatest asset is its vast technical expertise.

Five technical centers, 2 of which are located in Europe (in the UK and Germany), where 1600 engineers work to provide technical support. Technical support that develops into the development of specialized solutions to customer problems. The basis of the mission is customer satisfaction, and the mechanism is constant communication with the market. A highly qualified team of 8,700 sales engineers provides support in finding the optimal solution.

The company strives to be prepared for any emergency, and to ensure that activities do not stop if it occurs. As a comprehensive automation equipment manufacturer, SMC strives to fulfill its commitment to deliver products and maintain customer confidence by contributing to both sustainable development and the expansion of technological innovation.

Over the past few years, SMC has seriously promoted and supported environmental responsibility in order to minimize the negative impact on the environment.

SMC, as a leader in the field of pneumatic equipment, constantly strives for the latest and environmentally friendly solutions, giving the highest priority to reducing CO2 emissions. One of the key components of the systems approach is the design of compact and lightweight equipment. Smaller, lighter products require fewer raw materials and less time. In addition, the products themselves consume less energy. All these measures contribute to the reduction of CO2 emissions.

SMC Corporation manufactures the widest and most complete range of industrial automation equipment:

- Compressed air preparation systems. The preparation of compressed air is a necessary step in the operation of any industrial pneumatic system. The preparation process consists in removing various kinds of impurities from the air in the form of solid, liquid and gaseous inclusions, such as dust, condensate, scale, compressor oil, wear products of pneumatic equipment and other pollutants. In addition, the preparation includes pressure regulation and smoothing of its fluctuations, and, if necessary, the supply of lubricant for pneumatic devices.

- Pneumatic distributors. This is a device designed to distribute air flows in two or more external pneumatic lines, as well as control the actuators of pneumatic systems. The main functions of the pneumatic distributor are starting, stopping, changing the direction of the air flow.

- Valves. A mechanism designed to open, close, or regulate the flow of something when certain conditions occur.

- Filters. A device for isolating desirable components of the electrical signal spectrum and/or suppressing unwanted ones.

- Pneumothrottles. Regulating pneumatic equipment is designed to change the pressure and flow of compressed air by adjusting the opening of the flow section.

- Pneumatic cylinders. Devices for linear movement of the working body of machine tools and other mechanisms. They are actuators of pneumatic systems and are designed to convert the energy of compressed air.

- Electric drives. A controlled electromechanical system designed to convert electrical energy into mechanical energy and vice versa and control this process. A modern electric drive is a combination of many electric machines, devices and their control systems.

- Control and measuring equipment. A set of technical measuring instruments (measuring instruments, sensors, etc.) and auxiliary devices intended for control field observations and studies of the state of the structure and foundation.

- Fittings and pipes. The connecting part of the pipeline, installed for branching, turns, transitions to a different diameter, as well as, if necessary, frequent assembly and disassembly of pipes. Fittings also serve to hermetically seal the pipeline and other auxiliary purposes.

- Vacuum equipment. This is equipment with which you can obtain, maintain and use a vacuum for laboratory or industrial purposes.

We ship SMC stock products worldwide. Just contact our sales to get more information about price and availability.