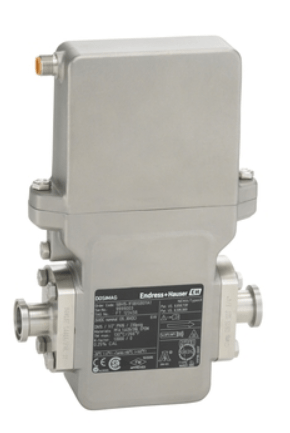

Endress+Hauser Proline Promag W10

Electromagnetic flowmeter

- Max.error: Volume flow (standard): В±0.5 % o.r. В± 1 mm/s (0.04 in/s)

- range: 9 dmВі/min to 162 000 mВі/h (2.5 gal/min to 100 000 gal/min)

- Max. pressure: PN 40, Class 300, 20K

- Overview +

- Comments +

Promag W10 is a flow meter for primary water and wastewater systems with an easy-to-use operating concept. Reliable measurements with consistent accuracy at 0 x DN at the inlet without pressure loss.

Proline Promag w 10 is used for basic measurement tasks, such as raw water sampling. The bidirectional measurement principle is virtually independent of pressure, density, temperature, and viscosity.

Endress Hauser Promag W10 Advantages:

- Suitable for basic measurement tasks such as raw water sampling.

- Flexible design – sensor with fixed or overlapping process connections. Suitability – EN ISO 12944 corrosion protection for underground or underwater installation. Increased plant availability – sensor meets industry requirements.

- International drinking water certifications. IP68 protection rating (type 6P housing). International drinking water certifications. Installation length: DVGW/ISO compliant.

- Optimum ease of use – operation with mobile devices and the SmartBlue app or touchscreen display. Simple, time-saving commissioning – guided parameter configuration in advance and in the field. Integrated heartbeat verification technology. System integration with HART, Modbus RS485. Flexible control via an app and optional display.

- 5WBBT2, DN1200 48"

- 5WBBT0, DN1000 40"

- 5WBB8H, DN800 32"

- 5WBB4H, DN400 16"

- 5WBB4F, DN450 18"

- 5WBB7H, DN700 28"

- 5WBB6H, DN600 24"

- 5WBB5H, DN500 20"

- 5WBB3S, DN375 15"

- 5WBB3H, DN300 12"

- 5WBB2F, DN250 10"

- 5WBB1F, DN150 6"

- 5WBB1Z, DN125

- 5WBB1H, DN100 4"

- 5WBB80, DN80 3"

- 5WBB50, DN50 2"

- 5WBB40, DN40 1 1/2"

- 5WBB2H, DN200 8"

- 5WBB25, DN25 1"

- 5WBB32, DN32

- 5WBBV0, AWWA 42"

- 5WBB3F, DN350 14"

- 5WBB65, DN65

- 5WBBE4, DN2400

- 5WBBE3, AWWA 90"

- 5WBBE2, DN2200

- 5WBBV3, AWWA 54"

- 5WBBT4, DN1400

- 5WBBV5, AWWA 60"

- 5WBBT6, DN1600

- 5WBBV6, AWWA 66"

- 5WBBT8, DN1800 72"

- 5WBBV9, AWWA 78"

- 5WBBE0, DN2000

- 5WBBE1, AWWA 84"

- 5WBBW9, AWWA 120"

- 5WBBF0, DN3000

- 5WBBW8, AWWA 114"

- 5WBBW7, AWWA 108"

- 5WBBE6, DN2600

- 5WBBW5, AWWA 102"

- 5WBBW4, AWWA 96"

- 5WBB9H, DN900 36"

5WBB1F-AAEAMBHP0CHA1S0MA1+AA

5WBB1F-AADAEBJA0DUA12HAA1+AA

5WBB1F-AAIAEMKM0BHD3KHMA1+AA

5WBB1H-AAEDMBHA0DUA1SGMA1+AA

5WBB1H-AADAMMJA0CQD321MA1+AA

5WBB1H-AAIAEBKM0BHD5K0AA1+AA

5WBB1Z-AAEDDMKN1BUD3KGAA1+AA

5WBB1Z-AADDMBJA0CQD321MA1+AA

5WBB1Z-AAIDMMAP3CUD3KGMA1+AA

5WBB25-AAIDEMAN1CUA1KHMA1+AA

5WBB25-AADAMMHA0DUA14HMA1+AA

5WBB25-AAEAMBJP3CUD5KGAA1+AA

5WBB2F-AAEDEMJM0CUD2SGAA1+AA

5WBB2F-AADAEMJM0DQA12HMA1+AA

5WBB2F-AAIDEMJN1BHD2K1AA1+AA

5WBB2H-AADAMBJP2BQD241AA1+AA

5WBB2H-AAIAEBKP1AUA1S0MA1+AA

5WBB2H-AADAMMJA0CQD241AA1+AA

5WBB32-AAEDEBKN1AUD5K1MA1+AA

5WBB32-AAIADBJN0AUN4K1MA1+AA

5WBB32-AAEDMBAP3CUD5S1MA1+AA

5WBB3F-AAEDMMHA0CUA1KGMA1+AA

5WBB3F-AAEDMBJP2BHD2K1AA1+AA

5WBB3F-AAIDEMKN2DHD1K0MA1+AA

5WBB3H-AAEDMBHP2BHD2K1MA1+AA

5WBB3H-AAIDDMJM0DUD2SGAA1+AA

5WBB3H-AADAEBJA0BQA14HMA1+AA

5WBB40-AAEAMBHP3CUD5S1MA1+AA

5WBB40-AADAEMJM0DQD210MA1+AA

5WBB40-AAIAEMKN1CUA2S1AA1+AA

5WBB4H-AAEDMBKA0CUD1KHAA1+AA

5WBB4H-AAIADMAM0CUD1KHMA1+AA

5WBB4H-AAIDMMAP2DUA1KHMA1+AA

5WBB50-AAEDDMJN1CHA2K1MA1+AA

5WBB50-AAIDMBHA0DUA1SGMA1+AA

5WBB50-AADAMMJP3BQA140AA1+AA

5WBB5H-AAGDDMJM0DUD1KHMA1+AA

5WBB5H-AAFAEMAN3CUD2KHMA1+AA

5WBB5H-AAKADMJN0DUA1K0AA1+AA

5WBB65-AAEAMBJP1BHD3K1MA1+AA

5WBB65-AADAEBHP3CQD341MA1+AA

5WBB65-AAIAMBKP1CUD3S0MA1+AA

5WBB80-AAEDEBKN0BHA2K1MA1+AA

5WBB80-AAIAMBKP2BUD5KHAA1+AA

5WBB80-AAEDMBJP2CHA1S1MA1+AA

Buy Endress+Hauser Proline Promag W10 with the best possible price and delivery terms on eltra-trade.com

eltra-trade.com is an electrical equipment shop. We have the status of the official representative of many European brands. We deliver to any country in the world. Our company is not an official distributor of all brands, but we can offer you competitive prices for all items in our catalog. We provide accurate delivery time information at the very beginning. We are the partner who can trust.

Comments

No comments yet