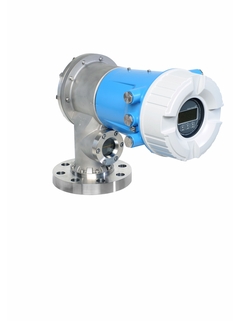

Endress+Hauser Proservo NMS81

Servo tank gauging instrument

up to 0.4 mm

Process temperature-200В°C...200В°C

(-328В°F...392В°F)

up to 25 bar (363 psi) abs

Max. measurement distance47 m (154 ft)

Main wetted parts316L, AlloyC276, PTFE

- Overview +

- Comments +

High precision servo measurement for liquid level, interface and density.

Measuring principleServo / Float Tank Gauging

Characteristic / ApplicationServo Tank Gauging: High precision measurement for liquid level, interface, spot density, profile density

Supply / Communication85-264 VAC

Ambient temperatureStandard:

-40В°C...60В°C

40В°F...140В°F)

For calibration to regulatory

Standards:

-25В°C...55В°C

(-13В°F...131В°F)

-200В°C...200В°C

(-328В°F...392В°F)

up to 25 bar (363 psi) abs

Wetted parts316L, AlloyC276, PTFE

OutputFieldbus: Modbus RS485, V1, HART

Analog 4-20mA output (Exi/ Exd)

Relay output (Exd)

Inputs:

Analog 4-20mA input (Exi/ Exd)

2-, 3-, 4-wire RTD input

Discrete input (Exd, passive/ active)

ATEX, FM, IEC Ex, NEPSI, EAC

OptionsRedundant fieldbus

Alu-coated or 316L housing

Weather protection cover

Guide wire assembly

Relief valve

Gas purging nozzle connection

Pressure gauge

Cleaning nozzle connection

Custody transfer level measurement

Interface measurement

Spot density, density profile measurement

47 m (154 ft)

Other approvals and certificatesOIML, NMi, PTB

Measuring principleServo / Float Tank Gauging

Characteristic / ApplicationServo Tank Gauging: High precision measurement for liquid level, interface, spot density, profile density

SpecialitiesCustody transfer level measurement

Interface measurement

Spot density, density profile measurement

85-264 VAC

Accuracyup to 0.4 mm

Ambient temperatureStandard:

-40В°C...60В°C

(-40В°F...140В°F)

For calibration to regulatory Standards:

-25В°C...55В°C

(-13В°F...131В°F)

-200В°C...200В°C

(-328В°F...392В°F)

up to 25 bar (363 psi) abs

Main wetted parts316L, AlloyC276, PTFE

Process connectionFlange:

DN80/3" / DN100/4" / DN150/6"

47 m (154 ft)

CommunicationOutputs:

Fieldbus: Modbus RS485, V1, HART

Analog 4-20mA output (Exi/ Exd)

Relay output (Exd)

Inputs:

Analog 4-20mA input (Exi/ Exd)

2-, 3-, 4-wire RTD input

Discrete input (Exd, passive/ active)

ATEX, FM, IEC Ex, NEPSI, EAC

Safety approvalsOverfill protection WHG

SIL

EN 10204-3.1

NACE MR0175, MR0103

OIML, NMi, PTB

OptionsRedundant fieldbus

Alu-coated or 316L housing

Weather protection cover

Guide wire assembly

Relief valve

Gas purging nozzle connection

Pressure gauge

Cleaning nozzle connection

Stilling well or guide wires for turbulent

application

Recommend PTFE displacer for high

viscosity application

Recommend AlloyC276 displacer for corrosive application

Interface measurement requires min. difference of 0.100 g/ml

between layers

Buy Endress+Hauser Proservo NMS81 with the best possible price and delivery terms on eltra-trade.com

eltra-trade.com offers a comprehensive range of industrial electrical products. We specialize in sourcing and delivering hard-to-find parts promptly. Our commitment to quality and competitive pricing makes us a preferred supplier. Partner with us for reliable and efficient electrical supply solutions.

Comments

No comments yet