Lenze 8400 Top Line

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

FI 8400 TopLine Inverter

Frequency converter 15844271

FI 8400 TopLine Inverter

Frequency inverter 15843213

Voltage: 400/500 V

Electrical Current: 16.5/13.2 A

FI 8400 TopLine Inverter

The frequency converter is used in conjunction with an asynchronous motor, automatically converting the AC frequency to the required parameters. Thus, the device controls the speed and torque of electric motors in a continuous process. Using an electrical device, you can not only fully automate production processes, but also achieve significant energy savings - up to 50%

The market of electrical equipment is represented by frequency converters for a wide range of applications. Devices can be both small power and high-voltage units. Modern equipment provides continuous process control in systems with asynchronous and synchronous motors.

But today we will talk in more detail about the Lenze 8400 TopLine.

What is Lenze 8400 TopLine?

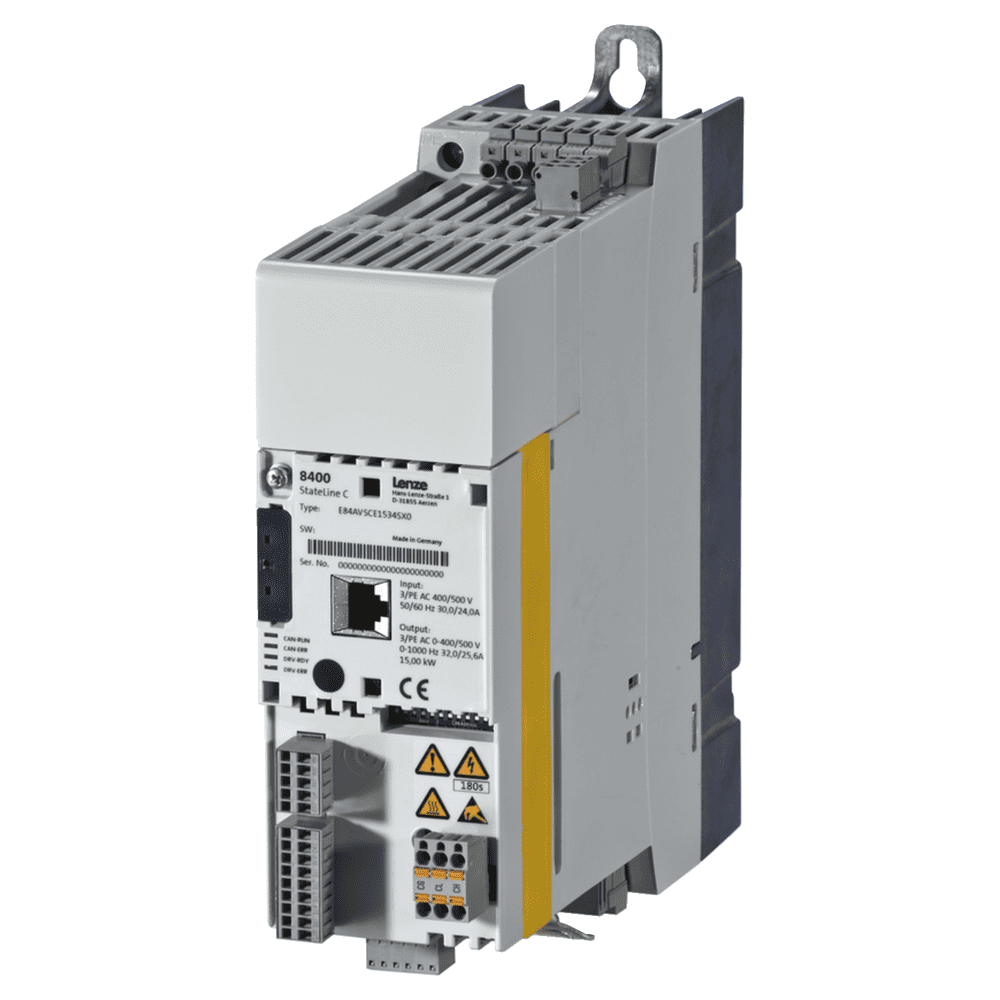

Asynchronous and synchronous servomotors can be operated with the Lenze 8400 TopLine in the power range at an input voltage of 230/240 V, 1/N/PE from 0.55 to 2.2 kW, and at 400/500 V, 3/PE from 0.37 to 45.0 kW. The devices are supplied with an appropriate control system and, in addition to the resolver input, are equipped with input interfaces for incremental and absolute encoders (single and multi-turn). The 8400 TopLine frequency converter (servo drive) completes the Lenze range of modular drive systems by matching the servo drive. It includes positioning with strict requirements in terms of dynamics and accuracy.

In terms of energy efficiency, the 8400 TopLine frequency inverter impresses with its patented standard VFC ECO mode voltage frequency control function. This mode intelligently adapts the magnetizing current to the actual requirements of the load, thereby reducing losses and saving energy (power consumption is reduced by up to 30%). With the VFC ECO mode, Lenze has succeeded in developing an intelligent concept that protects the environment and at the same time reduces energy costs.

Lenze 8400 TopLine Functions

Here are some of the main functions of Lenze 8400 TopLine:

- PID controller: used to control an external process with a feedback signal. The reference signal can come from an analog input, from the control panel via a preset reference, or via a serial interface. Measures the deviation of the stabilized value (eg pressure, speed, temperature, etc.) from the setpoint (so-called setpoint) and generates a control signal. The presence of this regulator inside the converter makes it possible to simplify the control system and refuse to use external regulators (controllers). The availability of a differential analog input allows the transmitter to be operated with two identical process sensors (for e.g. differential evaluation).

- A frequency converter complete with a programmable microprocessor controller can be used to create multifunctional control systems for electric drives, including those with redundant mechanical units.

- The use of an adjustable frequency drive allows you to save electricity by eliminating its unjustified costs, which occur with alternative methods of regulation with process flows by throttling, using fluid couplings and other mechanical control devices.

- Energy savings when using an adjustable electric drive for pumps averages 50% of the power consumed by pumps with throttle control. This determined the widespread introduction in industrialized countries of the controlled drive of pumping units. At the same time, companies offer various types of frequency converters for asynchronous pump motors.