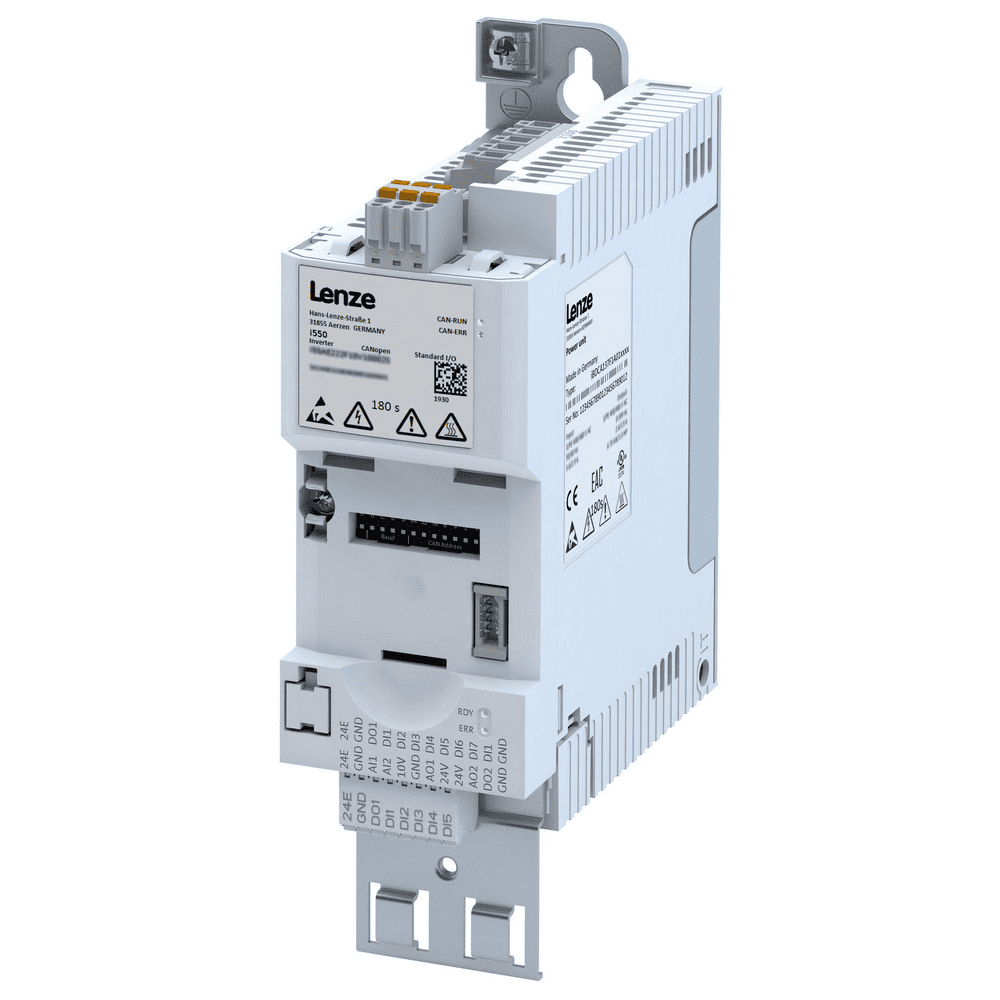

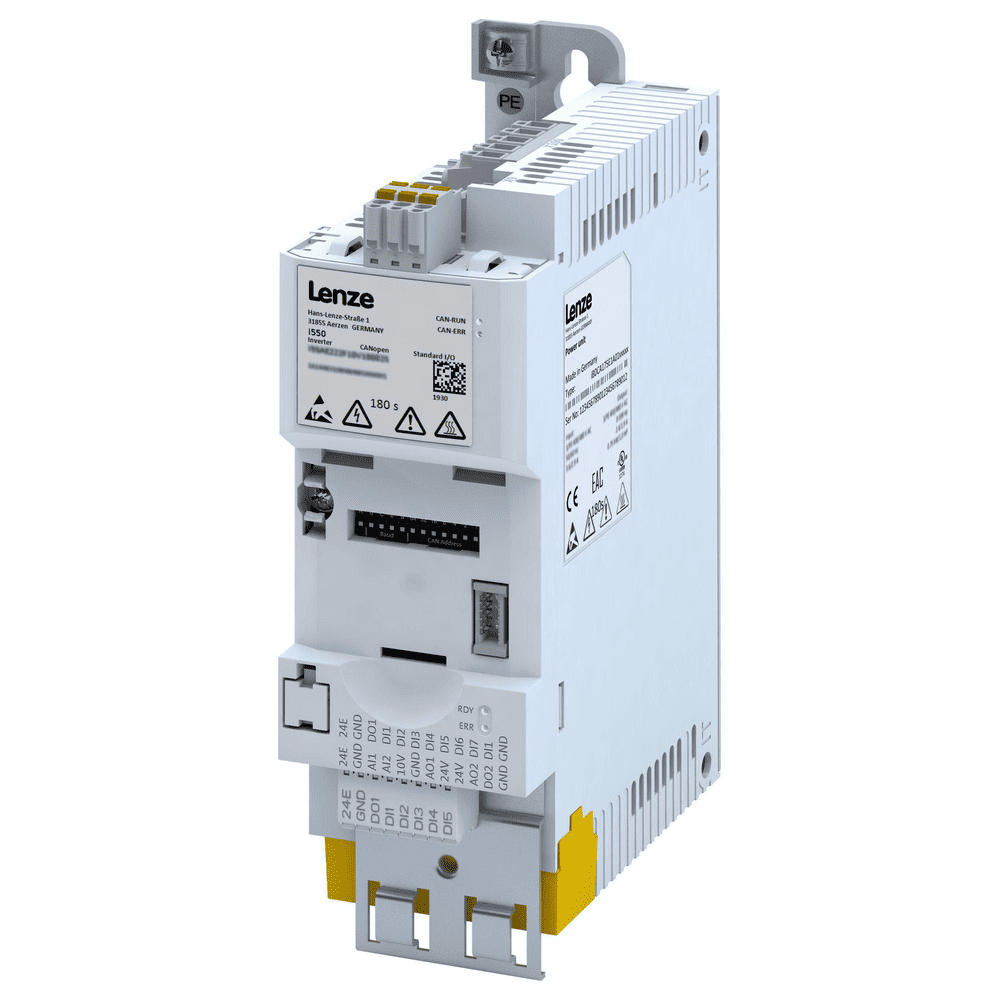

Lenze i550 Cabinet

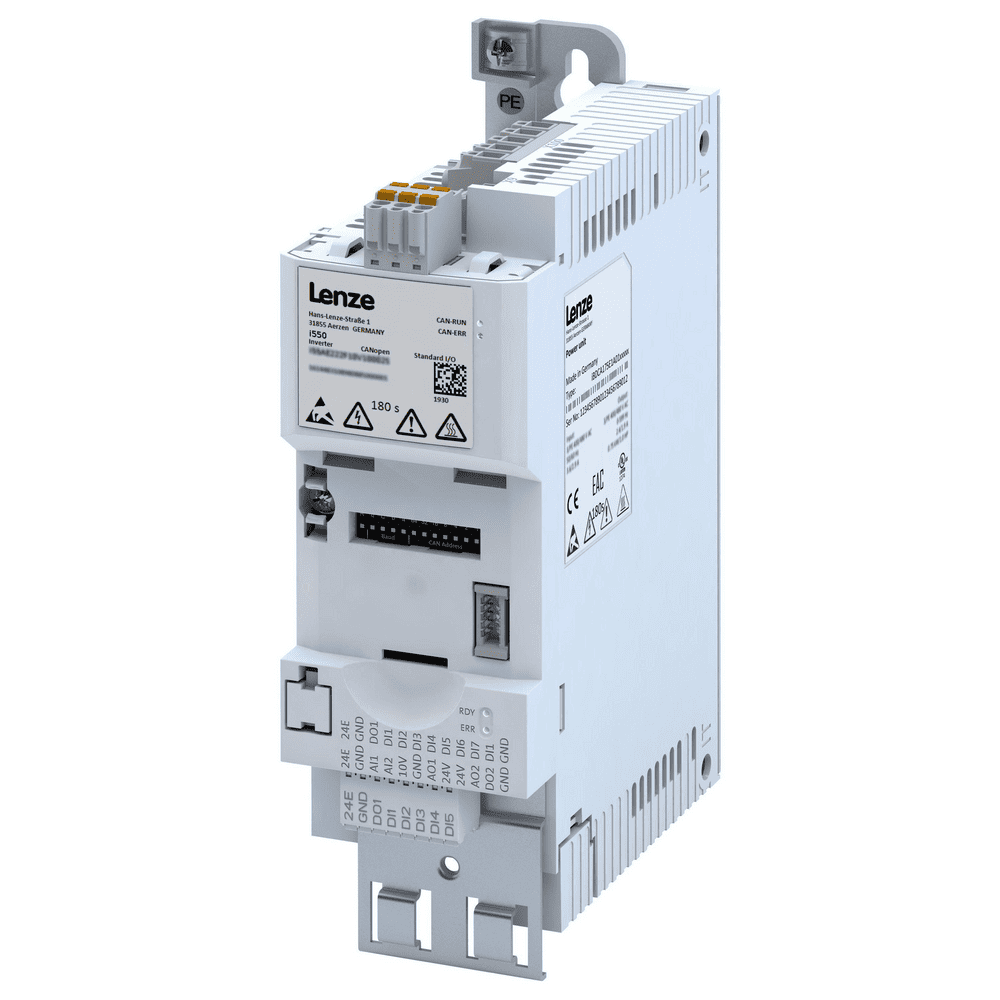

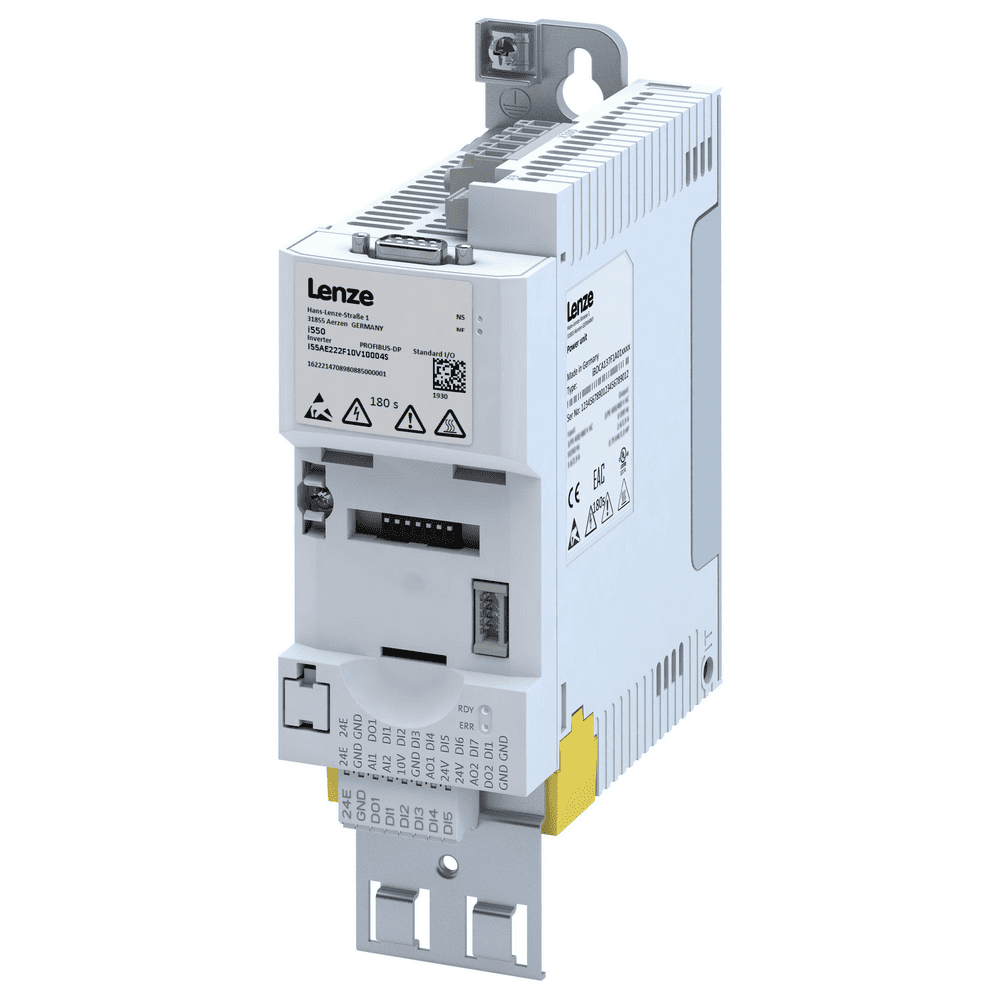

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

i550 Frequency inverter

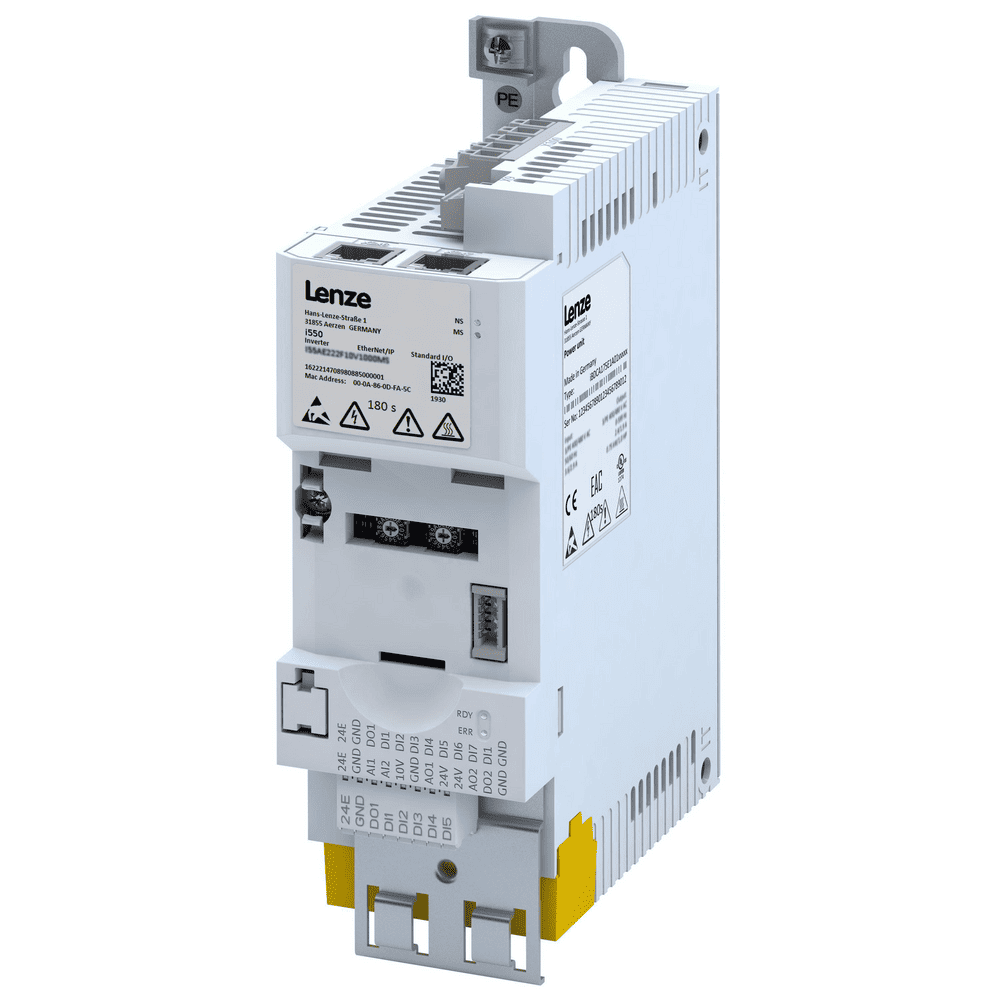

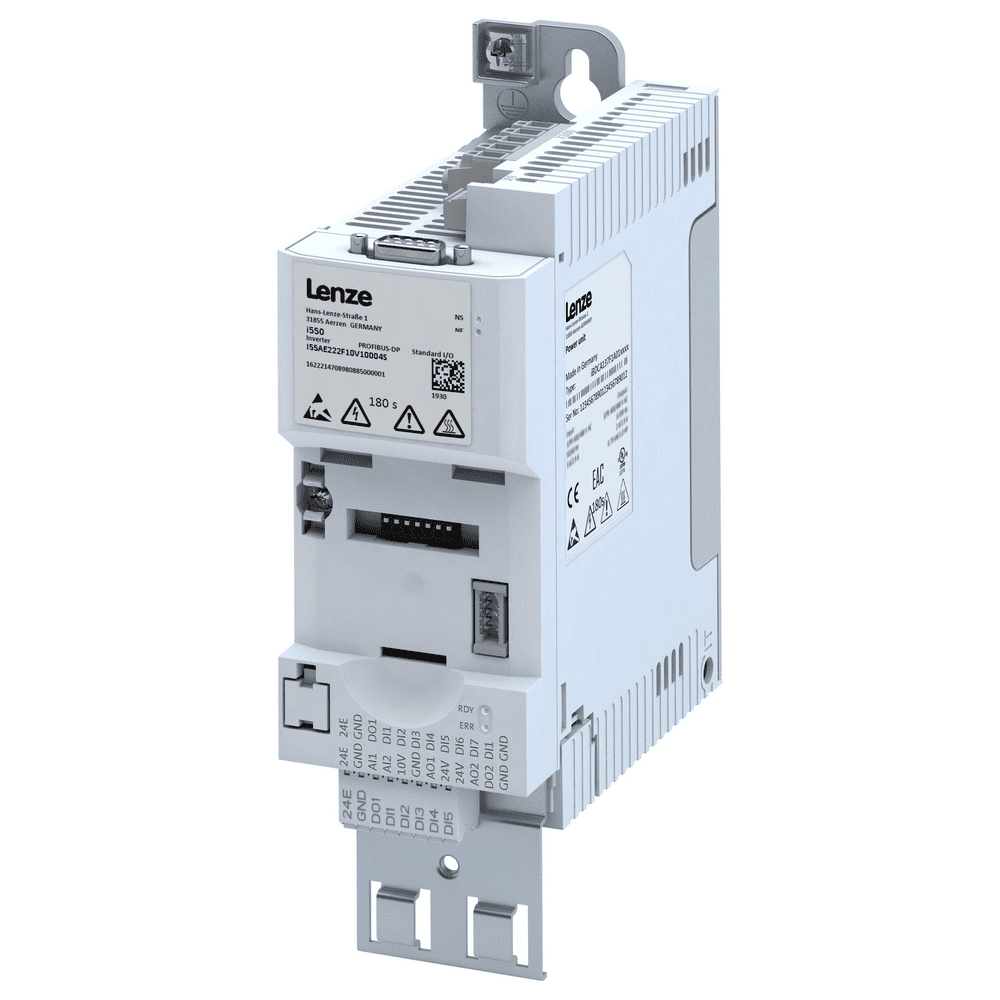

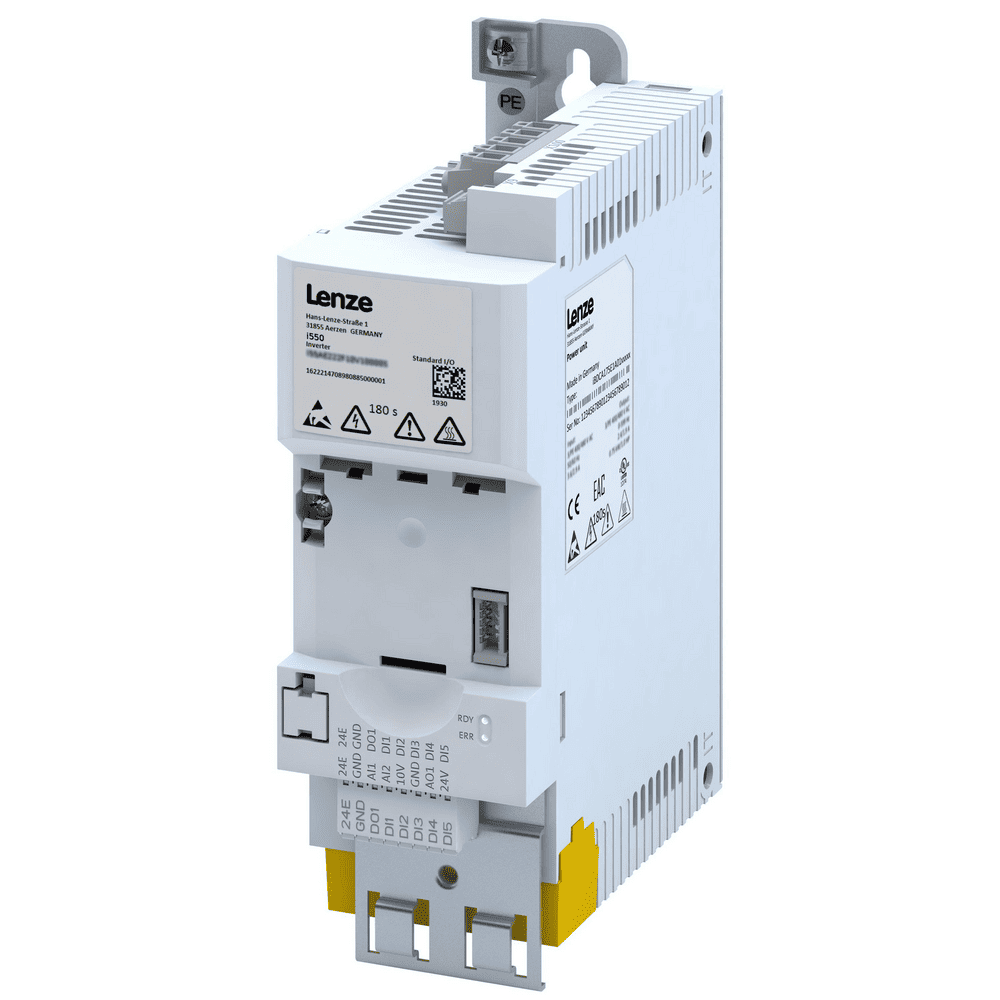

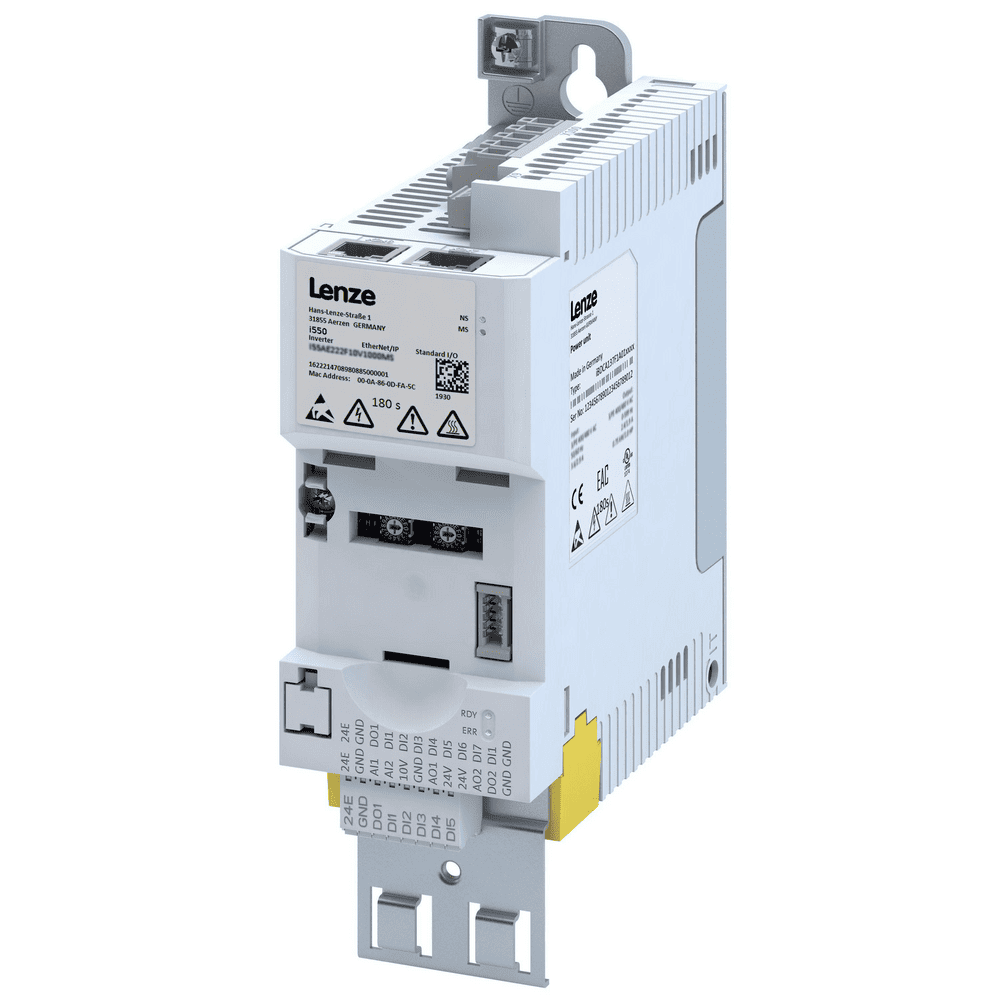

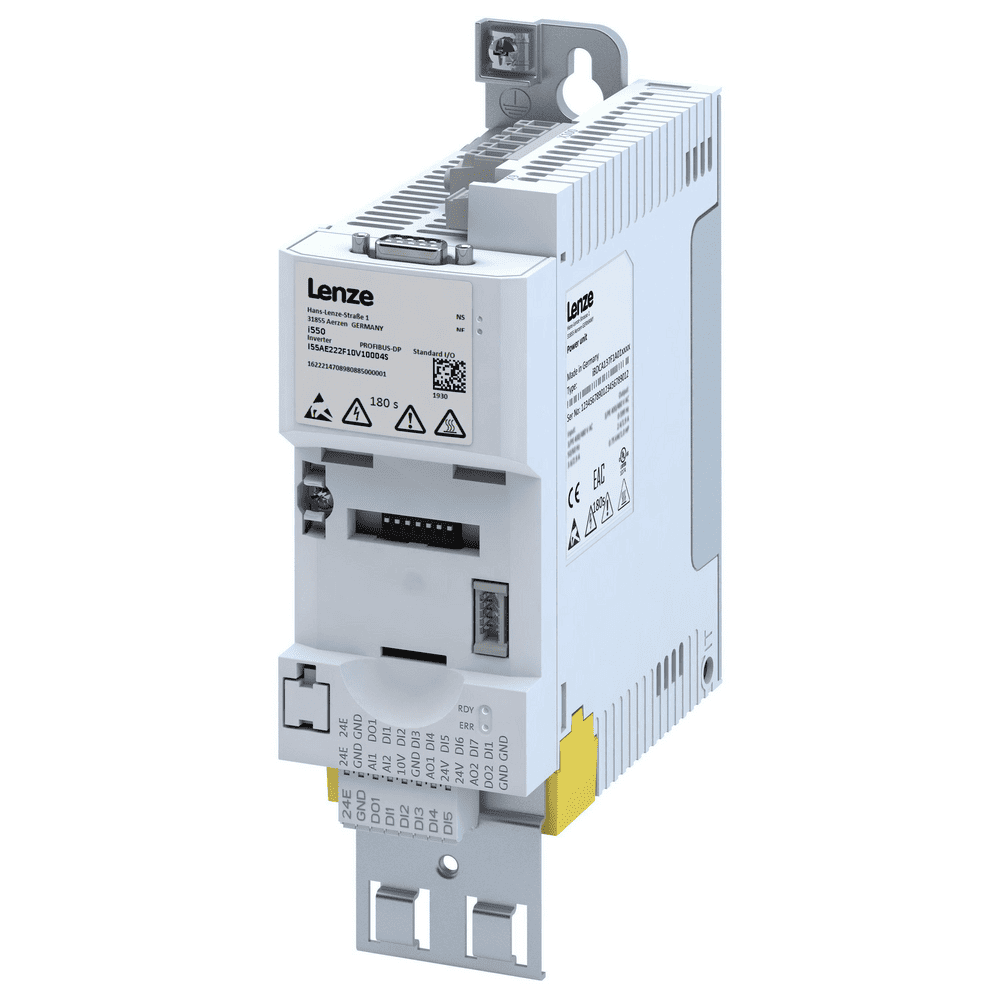

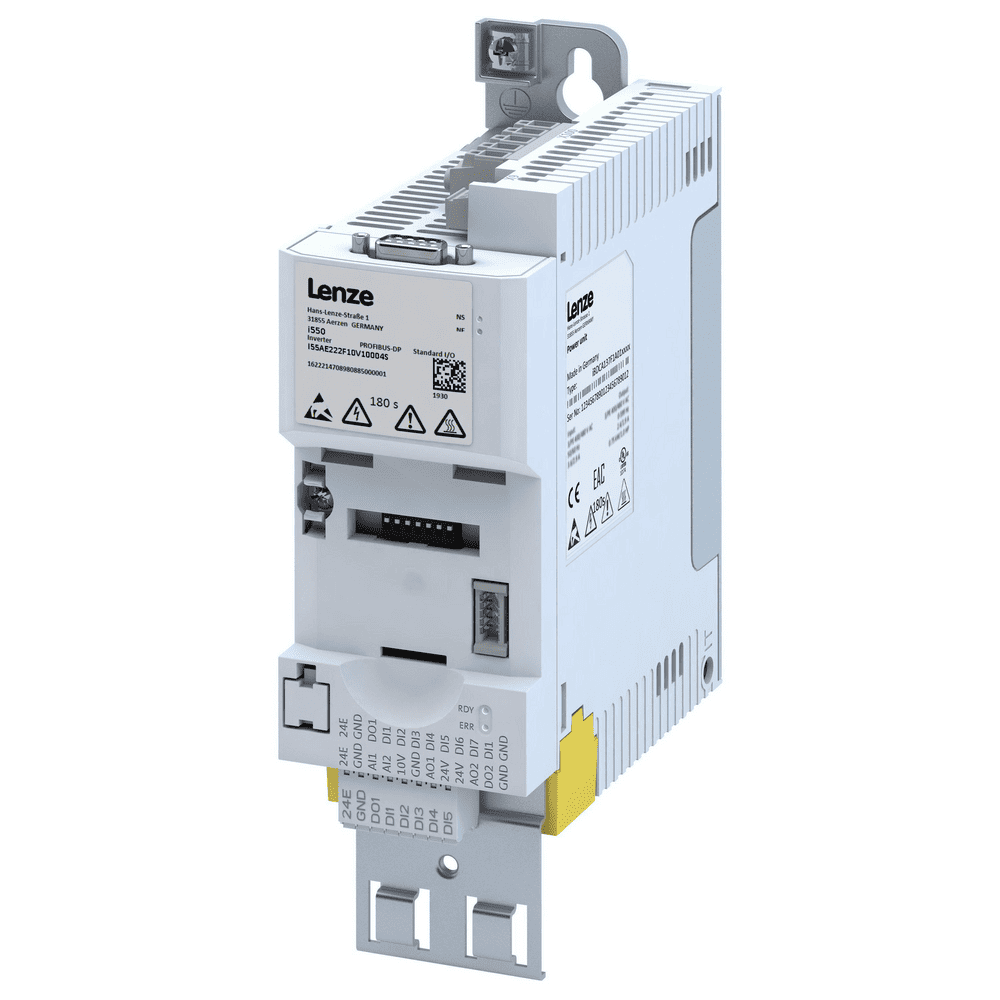

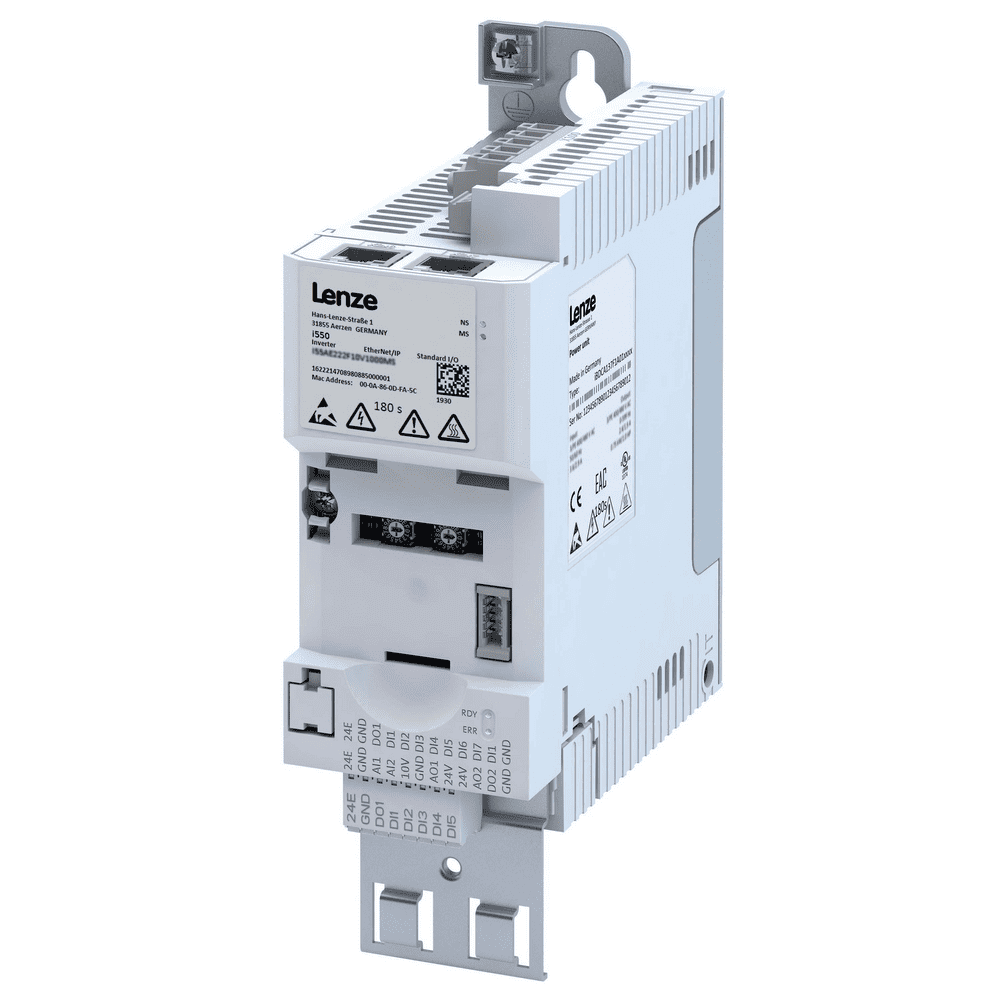

The i550 frequency converter is a compact control cabinet unit with scalable functionality. It provides universal application by supporting all standard fieldbuses and differs in versatility, reliability and ease of use. Innovative support for WLAN communication provides the shortest terms of commissioning and convenient diagnostics.

The requirements of the Green Design Recommendation are fully met.

I550 cabinet inverters are designed for installation in a control cabinet. Among the distinguishing features of these devices are slim design, scalability and exceptional usability.

These Lenze Drives are suitable for conveyor drives, trolleys, winders, extruders, pumps and many other machine and machine applications. Inverters are already compliant with the new version of EN 50598-2, which will soon come into force, and are available in the power range 0.25...110 kW (for light loads up to 132 kW).

Advantages:

- Saving space thanks to compact design: Width 60 mm (up to 4 kW), depth 130 mm (up to 11 kW), installation without gaps.

- Innovative communication support (including via WLAN).

- Modular design allows you to create different configurations of products in accordance with the requirements of the machines.

- Optionally it is fitted with Safe Torque Off (STO) conforming to SIL 3 (EN IEC 62061/EN IEC 61508) and Protection Performance Level e (EN ISO 13849-1).

- Innovative networking capabilities that enable commissioning in the shortest possible time.

- The device provides additional flexibility in use - you can order it as a complete device or as separate components (power supply, control unit and safety module), making it possible to create various product configurations.

Connectivity:

- 1 phase, 120 VAC current.

- 1 phase, 230 VAC current.

- 1/3 phase, 230 VAC current.

- 3 phase, 230 VAC current.

- 3 phase, 400/480 VAC current.

- Standard input-output (I/O) option:◦ 5 digital inputs; 1 digital output; PNP/NPN logic.

- Application input-output (I/O) option: 7 digital inputs; 1 digital output; PNP/NPN logic.

- Standard input-output (I/O) option: 2 analog inputs; 1 analog output.

- Application input-output (I/O) option: 2 analog inputs; 2 analog outputs.

- Frequency input: 0…100 kHz.

- 1 relay with NO/NC contact (24 V DC, max. 2 A; 240 V AC, max. 3 A).

- External 24V power supply and internal 24V power supply.

- Spring terminals, with detachable connection.

- Motor thermal contact monitoring.

Permissible overload: 200% for 3 s; 150% for 60 seconds.

The device has following engine control options: servo control with feedback; vector control of synchronous motors without sensors; sensorless Vector Control; energy saving function; v/f control with linear/quadratic characteristic (VFC plus); Control using a voltage-frequency (V/f) characteristic with feedback.

Functions:

- DC braking.

- Braking curve monitoring for low wear brake control.

- Dynamic braking using a braking resistor.

- S-shaped ramps for smooth acceleration and deceleration.

- Flying start loop, PID controller.

- Direct current (DC) circuit connection.

Security features: Safe torque off (STO).

Industrial networks: CANopen, Modbus RTU, Modbus TCP, IO-Link, EtherCAT, EtherNet/IP, PROFIBUS, PROFINET, POWERLINK.

Ambient temperature during operation:

3K3 (-10...+55 °C) EN 60721-3-3 (2.5%/°C derating above +45 °C).

You can buy Lenze I550 Drives at the lowest price from Eltra Trade company. Just contact our managers to get a quotation.