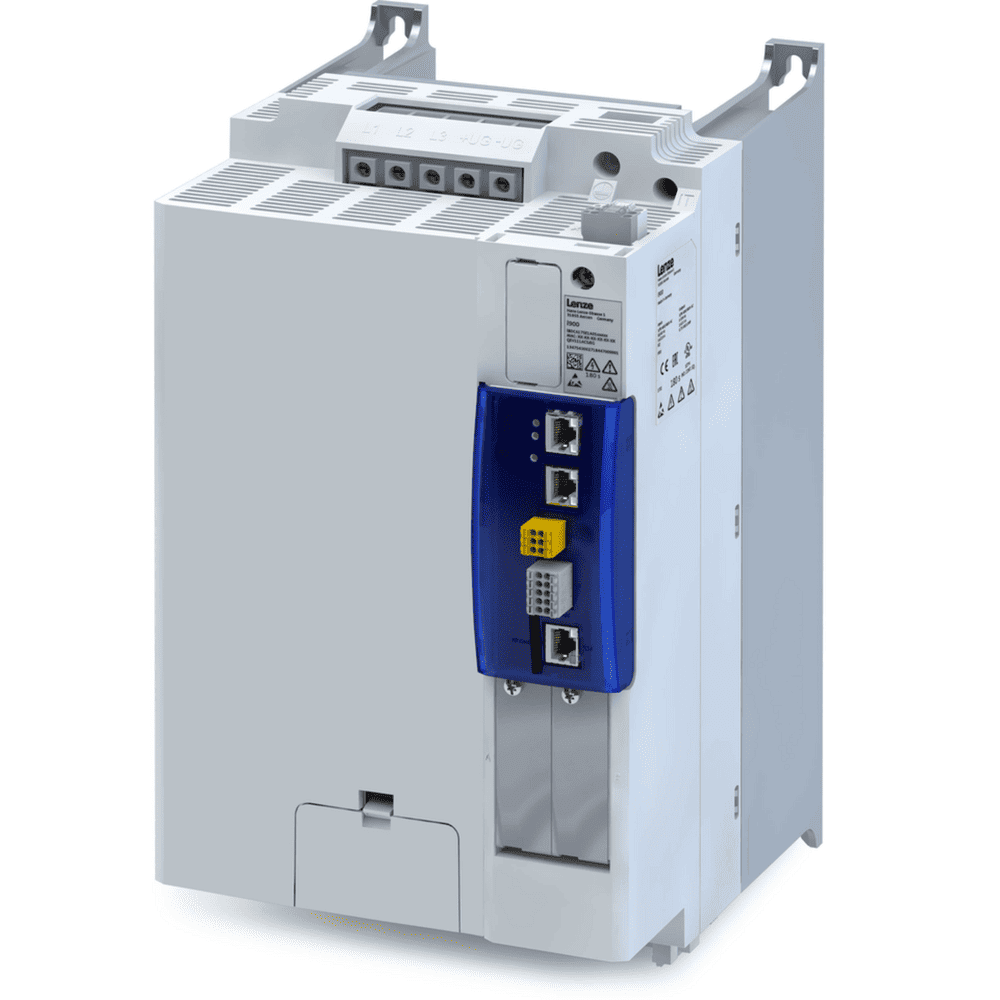

Lenze i950 cabinet

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

i950 servo inverter

I950 cabinet is a servo inverter with intelligent servo functions in the power range 0.37 - 110 kW.

Servo inverter is designed for precise, dynamic motion control while delivering impressive results for complex machine control tasks and single or multi-axis systems.

With only parameter setting required instead of programming, the i950 cabinet smart servo inverter enables easy integration into modular machine solutions based on ready-made applications for various technologies. The use of the same architecture, the same engineering solutions and application software, which have been successfully used for several decades, blurs the line between centralized and decentralized movement control. Application programming system FAST is becoming a versatile tool. If necessary, previously developed software modules allow for very easy customization and expansion. The i950 cabinet may be used in place of the i700 when the power range needs to be extended to 22-110kW. The requirements of the Green Design Recommendation are fully implemented.

Lenze I950 servo Advantages:

- Ready-made applications for various technologies, such as table positioning, electronic gear and winder;

- Single Wire Technology (OCT);

- Modular scaling for feedback system and fieldbus connection;

- Automatic settings feature for quick and easy controller setup;

- Built-in safety technology with broad functionalities up to SIL 3/PL e Cat. Four.

I950 Datasheet

Single axis: 0.37 ... 110 kW

Possibility of connecting:

3 phase 400 V a.c. current; 1 phase 230 V a.c. current; 3 phase 230 V a.c. current; 3 phase 480 Vac current

Inputs:

- 4 digital; one analog

- Safe inputs for connecting security sensors

- Resolver/multi-encoder feedback motor input

- Encoder/Resolver feedback load input

Outputs:

- 1 dig.

- Safe outputs for safe feedback

Other Features

- monitoring of temperature

- Post bus current

- Connecting encoder systems related to safety

- Single Wire Technology (OCT) via HIPERFACE DSL®

Connection interfaces:

- EtherCAT

- ethernet

- Ethernet/IP

- PROFINET

- FSoE Security Bus

- PROFIsafe safety bus based on PROFINET

- Working with Safety PLC

The following high requirements are applied to modern drive technology:

- positioning accuracy;

- speed stabilization;

- wide adjustment range;

- moment stabilization;

- overload capacity;

- high dynamics.

Today, electric drives with synchronous motors are increasingly used as servo drives. Servo converters are used to control the speed and torque of the servo motor.

Servo drives are widely used in various industries, and not all applications are highly dynamic. However, the ability to obtain highly stable or precise control, a wide speed control range, high interference resistance, small dimensions and weight are often decisive factors in their application. Today, it is difficult to find a field of activity where servo drives are not used.

The most important among them are:

- paper making;

- production of metal sheet;

- packaging;

- processing machines and machines;

- lifting and transport equipment;

- woodworking;

- production of building materials.

Eltra Trade provide the best process and delivery terms for full model range of Lenze I950 drives.