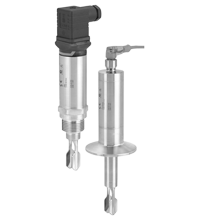

Pepperl+Fuchs LVL-A7H

Vibration Limit Switch

We ship

to United States of America

- Limit switch for liquids in the food sector

- External function test with test magnet

- Onsite function check possible thanks to LED indication

- Large selection of process connections for hassle-free installation in existing systems

- Easy to install even at points difficult to access due to compact design

- Rugged stainless steel housing

- Suitable for process temperatures up to 150 В°C (302 В°F)

- Cost-saving plug connections

- Approval as overfill protection and leak detection system acc. to WHG

Item Number:

LVL-A7H

Delivery standard: 3-6 weeks, depending on the country.

Condition:

new

Contact our experts

- Overview +

- Comments +

| Climate class | DIN EN 60068-2-38/IEC 68-2-38 |

| Degree of protection | IEC 60529 |

| Power consumption | - DC-PNP: < 975 mW - AC/DC: < 850 mW |

| Current consumption | - DC-PNP: < 15 mA - AC/DC: < 3.8 mA |

| Display elements | The LED display is on the connection side. - green LED: indication of ready to operate - red LED: fault indication - yellow LED: operating mode indication |

| Influence of medium temperature | -25 andmicro;m/В°C |

| Designation | see technical information (TI) |

| Mass | see technical information (TI) |

| Shock resistance | EN 60068-2-27 |

| Connection | - cable 5 m - valve plug NPT1/2 - valve plug QUICKON - valve plug M16 - plug M12 |

| Material | see technical information (TI) |

| Electromagnetic compatibility | NE 21 |

| Measuring frequency | approx. 1100 Hz in air |

| Influence of ambient temperature | negligible |

| Switching point | 13 mm В± 1 mm |

| Supplementary information | Statement of Conformity, Declaration of Conformity, Attestation of Conformity and instructions have to be observed where applicable. For information see www.pepperl-fuchs.com. |

| Sanitary compatibility | EHEDG , see approval (ZE) |

| Surface quality | Ra < 1.5 andmicro;m (EHEDG) Ra < 0.76 andmicro;m (EHEDG, 3-A) |

| Reference operating conditions | - ambient temperature: 25 В°C (+77 В°F) - process pressure: 1 bar (14.5 psi) - fluid: water (density: approx. 1 g/cm3, viscosity: 1 mm2/s) - medium temperature: 25 В°C (+77 В°F) - density setting: > 0.7 g/cm3 - switching time delay: standard (0,5 s, 1 s) |

| Measured value resolution | < 0.5 mm |

| Dimensions | see technical information (TI) |

| Measuring method | The tuning fork is brought to its resonance frequency by means of a piezoelectric drive. If the tuning fork is covered by liquid, this frequency changes. The electronics monitor the resonance frequency and indicate whether the tuning fork is freely vibrating or is covered by liquid. |

| Overspill protection | Z-65.11-554 (overspill protection acc. to WHG) Z-65.40-555 (leak detection system acc. to WHG) If you need the approvals also in paper form, select the option WH in the type code. |

| Switching current | max. 250 mA |

| Rated voltage | - DC-PNP: 10 ... 35 V DC, 3-wire - AC/DC: 20 ... 253 V AC/DC, 2-wire |

| Supplementary documentation | technical information (TI) manual (BA) approval (ZE) |

| Process connection | - thread ISO 228 G1/2, G3/4, G1 - DIN 11851 DN25 PN40, DN32 PN40, DN40 PN40 - thread ASME MNPT1/2, MNPT3/4, MNPT1 - thread M24 x 1,5 for flush-mounted installation in adapter - DIN 11851 DN25 PN40, DN32 PN40, DN40 PN40 (dairy pipe) - Tri-Clamp ISO 2852 DN25-38, DN40-51 - Flush-mounting in weld-in adapter Rd52, tuning fork can be aligned |

| Output type | switch output |

| Influence of medium pressure | -20 andmicro;m/bar |

| Hysteresis | max. 3 mm |

| Measured variable | density |

| Construction type | compact device device with short tube |

| Degree of protection | - IP65/67, NEMA 4X enclosure (plug M12) - IP65, NEMA 4X enclosure (valve plug) - IP65/68, NEMA 4X/6P enclosure (cable) - IP66/68/69, NEMA 4X/6P Enclosure (M12 plug for metal housing cover) |

| Switching time | - 0.5 s when tuning fork is covered - 1.0 s when tuning fork is uncovered - other switching times on request |

| Operating mode | MAX = maximum safety: The device keeps the electronic switch closed as long as the liquid level is below the fork. example application: overspill protection MIN = minimum safety: The device keeps the electronic switch closed as long as the fork is immersed in liquid. example application: dry running protection of pumps The electronic switch opens if the limit is reached, if a fault occurs or in the event of a power fails (quiescent current principle) |

| Measurement range | min. 0.7 g/cm3, optional> 0.5 g/cm3 |

| Vibration resistance | EN 60068-2-64 |

| Function test | function test with test magnet (optional accessory) |

| Non-repeatability | В± 1 mm acc. to DIN 61298-2 |

Buy Pepperl+Fuchs LVL-A7H with the best possible price and delivery terms on eltra-trade.com

eltra-trade.com offers a comprehensive range of industrial electrical products. We specialize in sourcing and delivering hard-to-find parts promptly. Our commitment to quality and competitive pricing makes us a preferred supplier. Partner with us for reliable and efficient electrical supply solutions.

People also buy

Comments

No comments yet