Pepperl+Fuchs Retroreflective Sensors

IN STOCK!

Connection 5 m fixed cable

- Miniature design

- Easy to use

- Very bright, highly visible light spot

- Full metal thread mounting

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Not sensitive to ambient light

- Rugged series in corrosion-resistant metal housing

- Extremely high switching frequency

- Clear and functional display concept for the operating modes

- Resistant against noise: reliable operation under all conditions

- Aluminum housing with high quality Delta-Seal coated

- Miniature design with versatile mounting options

- Detects transparent objects, i.e., clear glass, PET and transparent films

- Two machines in one: clear object detection or reflection operating mode with long range

- High degree of protection IP69K

- IO-link interface for service and process data

- Ultra bright LEDs for power on, weak signal indication and switching state

- Not sensitive to ambient light, even with switched energy saving lamps

- Waterproof, degree of protection IP67

- Protection class II

- User-friendliest photoelectric sensor series for standard applications

- Miniature design

- Not sensitive to ambient light

- Metal-reinforced fastening holes

- Version with infrared light

Retroreflective sensor (glass) OBG4000-R103-2EP-IO-V31

Array control panel with highly visible LED display

Flashing power on LED in case of short-circuit

MLV41 54 G 1371

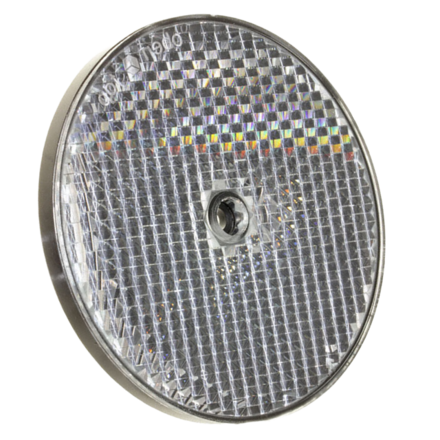

- Body material: stainless steel

- Lens material: PMMA

- Cable type: 2-wire, PVC

ref c110 2

- Compressive strength: > 10 MPa

- Tensile strength: > 10 MPa

- Impact strength: IK07

- Reflectance: > 80%

- Scattering angle: > 10°

- Efficient Line in a short M18 plastic housing for standard applications

- Two devices in one: choice of either clear object detection or retroreflective operating mode with a large detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Two devices in one: choice of either clear object detection or retroreflective operating mode with a large detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- DC voltage version

- glv18-55-g 73 120. Efficient Line in a short M18 plastic housing for standard applications

- Two devices in one: choice of either clear object detection or retroreflective operating mode with a large detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Sidelookerversion

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Sidelookerversion

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Sidelookerversion

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Version with front optical face

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Version with front optical face

- DC voltage version

- Efficient Line in a short M18 plastic housing for standard applications

- Very high detection range

- 4 LEDs indicator for 360?° visibility

- Optimized potentiometer design for a clear control button layout in the application

- Version with front optical face

- DC voltage version

pepperl fuchs ml100

Operating modes:

- Continuous

- Pulses

- Color distinction

- Difference in size

Functions:

- Error skipping

- Interval between pulses

- Adjustment of sensitivity

- Threshold adjustment

- No controls

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Full metal thread mounting

- Very bright, highly visible light spot

- Not sensitive to ambient light

- Miniature design

- No controls

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- No controls

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- No controls

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

- Miniature design

- Easy to use

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Very bright, highly visible light spot

- Full metal thread mounting

- Not sensitive to ambient light

Pepperl+Fuchs is a manufacturer of electrical devices for automation in various industrial sectors. In particular, the company is developing devices with retroreflective sensing technology. Since 1945, the company has come a long way in becoming and in our time has become one of the leading players in this market. Below we take a closer look at the retroreflective sensor from Pepperl+Fuchs.

What are Retroreflective Sensors

Pepperl+Fuchs retroreflective sensors are photoelectric sensors that use the interruption of a reflected light beam to detect objects. The sensor has a light beam emitter and a receiver/detector element built into the same housing. The retroreflector reflects the emitted light beam and returns to the sensor. When an object is placed between the sensor and the reflector, it interrupts the beam. The absence of a light beam causes the sensor to change its output signal.

When an object enters the area between the reflector and the sensor, it blocks the passage of the light beam. This interruption causes the light beam to scatter, and the sensor detects the change. This then causes the output to change.

Types of Retroreflective Sensors

Retroreflective sensors work according to the following principle. The device has a special retroreflective mode, establishing a light path between the sensor and a special reflector. Thus, when an object interrupts the light beam, the sensor immediately detects it. Stray light sensors provide a limited sensitivity range, while retroreflective sensors provide more comprehensive coverage. Some of these sensors use a visible red LED to assist with reflector installation and alignment. And a corner cube reflector is used to accurately return light energy along a parallel axis to the receiver.

Retroreflective sensors are available in various types, which we will discuss below.

- Sensors with a polarizing filter. The polarizing filter in such devices is used to eliminate false signals that can occur if a bright target passes in front of the reflective sensor. And the device's filter allows the sensor to easily detect objects with high reflectivity (such as glossy details).

- Sensors for precise object detection. The Transparent Object Detection Sensor is an exceptional reflective mode photoelectric sensor that detects transparent objects that standard reflective sensors cannot detect. Using a low hysteresis circuitry, the sensor detects small changes in illumination that are characteristic of detecting apparent objects. The Clear Object Detection Sensor used polarized filters on the sensor's transmitter and receiver to reduce false alarms caused by target reflections.

- Sensors with foreground suppression. Such devices are designed to suppress the foreground. Such devices are equipped with a photoelectric reflector mode that avoids mistakenly identifying glossy targets as a reflector when they are at a certain distance. This device mode is well suited for detecting pallets wrapped in shrink tape since the sensor in reflector mode can mistake a glossy coating for a reflector and not change its state. Optical openings in front of the transmitter and receiver elements in the sensor body create an area for error-free detection of reflective depolarized material.

- Reflector area sensor. This type of sensor is equipped with several transmitters and receivers in one housing. This way, the device can form a continuous wide or high detection zone in the corresponding range.

Reflective Tape Retroreflective Sensors

Reflective tapes and reflectors from Pepperl+Fuchs are designed for use with photoelectric retroreflective sensors to ensure optimum device performance. Reflective tape is available in various shapes, sizes, temperature ranges, and mounting options. Thus, the tape is suitable for all types of retro-reflective sensors, such as laser and polarized ones.

Benefits and Applications of Pepperl+Fuchs Retroreflective Sensors

The Pepperl+Fuchs photoelectric sensor with reflector has several advantages and is widely used in industry and automation. Let's take a closer look at these two points.

Advantages of these sensors.

- Contactless detection. Retroreflective sensors operate without direct contact with the target, reducing wear on both the sensor and the target. This non-contact reading minimizes the need for maintenance and extends the sensor's life.

- Long detection range. Reflective sensors usually have a long range, which allows them to detect objects over long distances. This characteristic makes them suitable for applications where objects are not close to the sensor.

- Reliable detection. Pepperl+Fuchs retroreflective sensors ensure reliable detection even under challenging conditions. They are designed to be reliable and stable in harsh industrial environments.

- Background suppression. Some retroreflective sensors offer background suppression capabilities, allowing them only to detect objects within a specific range of distances, ignoring objects outside that range. This feature can be helpful in cluttered environments.

- Versatility. Reflective sensors can detect various materials and types of objects, making them suitable for a wide range of applications.

The most common areas of application for this type of sensor.

- Presence/absence detection.

- Object counting.

- Loading and unloading works.

- Control of doors and gates.

- Level measurement.

- Machine safety.

- Parking systems.

Installation and Maintenance of Retroreflective Sensors

Now let's move on to some tips on installing and maintaining a retroreflective photoelectric sensor properly.

- Place the sensors in ideal conditions. When placing sensors for long-term outdoor measurements, solar sensors should be placed where they will not be in the shadow of surrounding objects such as trees or power poles. Avoid locations where the sensors may be exposed to drops or splashes of water.

- Install the sensor correctly. Each sensor manual contains installation guidelines. The sensors must be mounted level to ensure accurate and consistent measurements, and the sensor cables must be installed to point to true north in the northern hemisphere or true south in the southern hemisphere to minimize azimuth error.

- Check wiring connections. Make sure your wiring is secure and properly connected. Intermittent and often annoying problems can occur when the wiring is not making good contact with the controller/datalogger being used.

- Wire grounding. Most sensors ship with a cable shield that must be grounded to reduce electromagnetic interference (EMI). The shield wire is usually bare.

- Cable connectors. Pepperl+Fuchs offers built-in cable connectors that make removing sensors from recalibration setups easy. When disconnecting the sensor for a long time, protect the remaining half of the connector from water and dirt with electrical tape or other means. Connectors are designed to be hand tightened securely only to avoid over-compression.

- Clean the sensor. Blocking the optical path between the target and the detector can result in low readings. Dust and dirt can be removed from the sensor disk using a non-abrasive cloth or cotton swab moistened with deionized water or a window cleaner. Calcium deposits from irrigation water leave a thin white film on the surface that can be removed with a dilute acid like vinegar. Infrared radiometers may have spider/insect or wasp nests in the opening leading to the filter. If spiders/insects are a problem, repellent should be applied around the entrance to the aperture (not on the filter).

- Know what you are measuring. Familiarity with sensor specifications, operation, and measurements will help you recognize errors before data stored for days or weeks becomes unreliable and unusable.

- Calibrate the sensor when necessary. Occasionally, you need to perform calibration procedures on your sensor. Thus, you can prevent incorrect detection of objects in time, and ensure more efficient operation of the device.