Pepperl+Fuchs Photoelectric Sensors

IN STOCK!

Connection 5 m fixed cable

- Miniature design

- Easy to use

- Very bright, highly visible light spot

- Full metal thread mounting

- Clearly visible LEDs for Power ON, switching state and weak signal indication

- Not sensitive to ambient light

- Rugged series in corrosion-resistant metal housing

- Extremely high switching frequency

- Clear and functional display concept for the operating modes

- Resistant against noise: reliable operation under all conditions

- Aluminum housing with high quality Delta-Seal coated

- Miniature design with versatile mounting options

- Extended temperature range

-40?°C ... 60?°C - High degree of protection IP69K

- IO-link interface for service and process data

- Miniature design with versatile mounting options

- IO-link interface for service and process data

- Various frequencies for avoiding mutual interference (cross-talk immunity)

- Extended temperature range

-40В°C ... 60В°C - High degree of protection IP69K

- Miniature design with versatile mounting options

- Detects transparent objects, i.e., clear glass, PET and transparent films

- Two machines in one: clear object detection or reflection operating mode with long range

- High degree of protection IP69K

- IO-link interface for service and process data

- Miniature design with versatile mounting options

- Best background suppressor in its class

- Precision object detection, almost irrespective of the color

- Extended temperature range

-40?°C ... 60?°C - High degree of protection IP69K

- IO-link interface for service and process data

- Safety control unit

- For evaluating safety thru-beam sensors PSE4-SL

- Safety category 4 according to EN61496-1

- 24 V DC supply voltage

- 2 safe output contacts

- Performance level PLe (EN13849-1) is attainable

- Component of PSE4 modular system

- Ultra bright LEDs for power on, weak signal indication and switching state

- Not sensitive to ambient light, even with switched energy saving lamps

- Waterproof, degree of protection IP67

- Protection class II

- User-friendliest photoelectric sensor series for standard applications

- Miniature design

- Not sensitive to ambient light

- Metal-reinforced fastening holes

- Version with infrared light

R2000

- Working distance range: 30 to 100 meters

- Angle resolution: 0.5 to 1 degree

- Scanning frequency: 20 to 40 Hz

- Number of inputs/outputs: 1 to 4

- pepperl fuchs r2000 price

Pepperl+Fuchs SLCS90-2400-R safety light curtain

- Type of protection: Class 2, type 4

- Number of receivers and emitters: 2

- Power supply voltage: 24 V DC

- Operating temperature range: -20...+70 °C

visolux pepperl fuchs

- Measurement type: distance, speed, direction, and size.

- Signal type: Analog, digital and switching.

- Environmental protection: Protection against dust, moisture and explosions.

- Mounting: surface mounted, flush mounted, and pocket mounted.

Diffuse mode sensor OBD800-R103-2EP-IO-V31

Triangulation sensor (BGS) OBT300-R103-2EP-IO-V31

Retroreflective sensor (glass) OBG4000-R103-2EP-IO-V31

Plastic fiber optic

- Housing: M18

- Not sensitive to ambient light

- IP67

- Very high detection rang

Miniature design with versatile mounting options

Best background suppressor in its class

Precision object detection, almost irrespective of the color

Miniature design with versatile mounting options

Best background suppressor in its class

Precision object detection, almost irrespective of the color

Microwave motion sensor with intelligent functions

Array control panel with highly visible LED display

Flashing power on LED in case of short-circuit

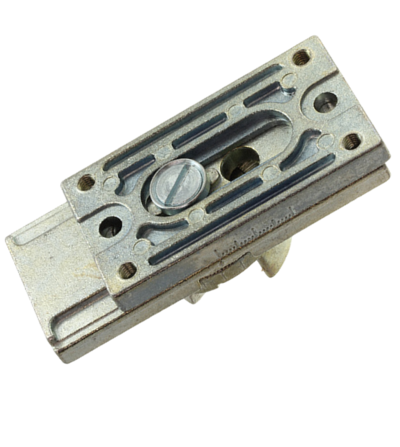

HPV D13

- Current consumption: < 10 mA

- Reverse polarity protection: Yes

- Short circuit protection: Yes

- On/off delay time: < 2ms

- Operating temperature: -20°C...+70°C

LK28 Z F1 31 116

- Type: infrared LED

- Wavelength: 870 nm

- Rise/fall time: < 2 µs

| Maximum DC Voltage | 30V |

| Response time | 0.5 ms |

| Maximum Current | ≤35 mA |

MLV41 54 G 1371

- Body material: stainless steel

- Lens material: PMMA

- Cable type: 2-wire, PVC

- Distance measurement using object

- Measuring method PRT (Pulse Ranging Technology)

- Accurate, clear, and reproducible measuring results

- Minimal black-white difference

- Red laser as the light emitter

- Version with IO-Link interface

- Version with laser class 2

VS18 M LAS 76a 118

- Degree of protection: IP67

- Body material: Stainless steel

- Connector: M12, 4-pin

- 0 ... 400 mm , adjustable

- 0 ... 25 mm

- 0 ... 400 mm

mh4 2681 uni

Traction force:

- Maximum static traction force: 200 N

- Maximum dynamic traction force: 100 N

Moment:

- Maximum static moment: 10 Nm

- Maximum dynamic torque: 5 Nm

Sensors - in automatic control systems - are sensitive elements or devices that perceive the value of the controlled parameter of the object and issue a signal to the device for comparing this value with the specified value, while generating a difference or mismatch signal, which through other devices affects the object of regulation. Today we will talk about photoelectric sensors in more detail.

What is a Pepperl+Fuchs Photoelectric Sensor?

In industry, specialized devices such as photoelectric sensors are actively used, allowing the most accurate detection of an incoming object without needing physical contact. They are used when installing various equipment, come in different types, and differ in the principle of operation. You can choose a suitable device according to its properties and consider the situation in which such a sensor will be used.

Pepperl+Fuchs photoelectric sensors are optical sensors, which consist of a light source, a light receiver, and a signal output and control circuit. They can detect the presence of objects and sometimes the state of the surface.

When the emitted light is interrupted by an object in the immediate vicinity, the light receiver detects this change and switches the sensor output on or off. Some proximity sensors can even determine the distance to an object.

Different Types of Photoelectric Sensors

Cheap photoelectric sensors according to the principle of operation are divided into three types:

- Barrier: the transmitter and receiver of the light beam (radiated by the LED) are in separate housings, which are installed opposite each other on the same axis.

- Reflector: the transmitter and receiver of the light beam are in the same housing, and a reflector is used to reflect the beam.

- Diffusion: the transmitter and receiver of the light beam are in the same housing. The receiver takes into account the intensity of the beam reflected by the controlled object.

Photoelectric Sensors Working Principle

The scope of applicability of photoelectric position sensors covers a wide industrial spectrum. Sensors of this type help to solve problems related to the management of technological processes of production, where it is necessary to detect, position, or simply count certain objects.

Due to their versatility, photoelectric sensors are today the most widely used where industrial automation is needed. They are distinguished by the ability to carry out non-contact measurements and counting of objects and display the relevant information in the form of a digital signal that is easily perceived and processed by any modern controller.

Beam interruption principle

Two housings - an emitter and a receiver, make up one device. They are installed on opposite sides of the place where the object is supposed to pass. The receiver is statically fixed opposite the emitter so that the unrefracted beam from the emitter always hits the detector of the receiver.

The working range (the size of the fixed object) is practically unlimited, and the objects being determined can be both transparent and opaque.

If the object is opaque, then the ray is simply overlapped, and blocked by the object. If the object is transparent, the beam is deflected or scattered so that the receiver does not see it until the object leaves the place of its detection. This ensures the high reliability and accuracy of the photoelectric sensor, based on the principle of beam interruption. These sensors are capable of operating at distances between the emitter and receiver from a few centimeters to tens of meters.

The principle of reflecting a beam from a reflector

The sensor consists of two parts - an emitter and a reflector. The receiver and emitter are in the same housing, which is fixedly mounted on one side of the area under study, and on the other side a reflector (reflector) is installed. Different reflectors allow this type of sensor to be used at different distances, and the sensitivity of the receiver can sometimes be adjusted.

These sensors are also suitable for detecting glass and other highly reflective surfaces. As is the case with sensors based on the principle of the interrupted beam, reflector-based sensors allow you to measure the overall dimensions of objects or simply count them.

Since there is only one case, the device as a whole requires less space for installation, sometimes this is an important advantage, especially for automation systems requiring compactness. These sensors are capable of operating at distances between the housing and the reflector from a few centimeters to several meters.

The principle of reflection of a beam from an object

The whole device is a single housing containing an emitter and a receiver capable of responding even to a scattered beam reflected from an object. Models of sensors of this type are mostly of low cost, occupy the least space for installation, they do not need a reflector.

It is enough to statically fix the sensor near the area under study, and adjust its sensitivity in accordance with the type of surface of the object being detected. Sensors of this type are suitable for working at short distances to the objects under study, on the order of several tens of centimeters, for example, with products moving on a conveyor belt.