ABB DCS 500 fault codes

05.07.2024

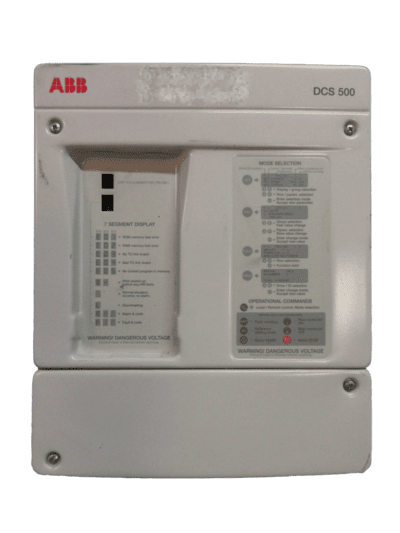

In the realm of industrial automation, the ABB DCS 500 stands out as a robust and reliable direct current (DC) drive system. This versatile piece of equipment is engineered to provide precise control over DC motors, making it an integral component in various industrial applications. Whether it's in manufacturing, processing, or any other sector requiring fine-tuned motor control, the ABB DCS 500 delivers performance that meets the high demands of modern industry.

What is ABB DCS 500?

The ABB DCS 500 is designed to offer advanced motor control solutions that enhance the efficiency and reliability of industrial operations. Here’s a closer look at its basic features and specifications:

- Advanced Control Algorithms: The ABB DCS 500 utilizes sophisticated control algorithms to ensure optimal motor performance. These algorithms allow for precise speed and torque control, which is essential for maintaining the efficiency and productivity of industrial processes.

- Robust Construction: Built to withstand harsh industrial environments, the ABB DCS 500 features a rugged design that ensures long-term durability. Its sturdy construction minimizes downtime and maintenance costs, making it a cost-effective solution for industrial automation.

- User-Friendly Interface: The drive system is equipped with an intuitive user interface that simplifies operation and troubleshooting. This ease of use is particularly beneficial for operators and technicians who need to quickly address any issues that arise during operation.

- High Power Output: The ABB DCS 500 is capable of delivering high power output, making it suitable for applications that require significant motor power. This capability is crucial for industries where powerful motor performance is a necessity.

- Extensive Diagnostic Capabilities: One of the standout features of the ABB DCS 500 is its comprehensive diagnostic system. This system provides real-time monitoring and fault detection, allowing operators to identify and resolve issues promptly. The ability to quickly diagnose and address faults helps to maintain continuous operation and reduces the risk of costly downtime.

Key Features and Specifications of ABB DCS 500

The ABB DCS 500 is a versatile digital DC drive designed for a wide range of applications with DC motors up to 5 MW. It is available in two versions: for two-quadrant and four-quadrant motor control.

Main characteristics

- Rated current: from 25 A to 5150 A

- Supply voltage: 3 x 230-1000 V

- Degree of protection: IP54

- Cooling: fan

- Control inputs/outputs: analog and digital inputs/outputs, serial data bus

- Ambient temperature: from -20°C to +50°C

- Additional options: EMI filters, regenerative brakes, positioners

Advantages of using ABB DCS 500

The ABB DCS 500 offers a number of advantages that make it an excellent choice for a wide range of applications. Here are some of the key benefits:

1. Wide power range: The DCS 500 is available in a wide range of rated currents, from 25 A to 5150 A, making it suitable for a wide range of applications, from small machines to large industrial installations.

2. Two-quadrant and four-quadrant engine control: The DCS 500 offers both two-quadrant and four-quadrant motor control. Two-quadrant control allows the motor to rotate in one direction and brake, while four-quadrant control allows the motor to rotate in both directions and brake in both directions. This provides the flexibility and control precision required for many applications.

3. High productivity: The DCS 500 offers fast response times, high positioning and speed accuracy, making it ideal for applications where precision and dynamic performance are required.

4. Reliability: The DCS500 ABB is designed using robust components and has a high degree of protection, making it reliable and durable.

5. Ease of use: The DCS 500 is easy to set up, operate and maintain.

6. Energy efficiency: The DCS 500 offers a number of features that help improve energy efficiency, such as regenerative braking, which allows energy to be fed back into the grid when the motor is braking.

7. Reduction of operating costs: The reliability, durability and energy efficiency of the DCS500 ABB help reduce operating costs over the life of the drive.

8. A wide range of options: The DCS 500 offers a wide range of options such as EMI filters, regenerative brakes and positioners that allow it to be adapted to specific application needs.

9. Compliance with standards: The DCS 500 complies with all relevant industry standards and regulations.

Fault codes in ABB DCS 500

The ABB DCS 500 DC drive is equipped with a self-diagnosis system that detects and records faults. Each fault has a unique code that can be displayed on the drive display or via the configuration software.

This table the most common ABB DCS 500 fault codes list, along with descriptions, possible causes and troubleshooting steps.

| Fault Code | Description | Possible Cause | Action |

| E001 | Overvoltage | Incorrect supply voltage | Check supply voltage and connections. |

| E002 | Undervoltage | Incorrect supply voltage | Check supply voltage and connections. |

| E003 | Motor Overload | Motor overload, motor fault | Check motor load and motor condition. |

| E004 | Open Circuit | Open circuit in drive or motor | Check all connections and cables. |

| E005 | Power Part Overtemperature | Cooling system fault | Check cooling system and fans. |

| E006 | Control Overtemperature | Cooling system fault | Check cooling system and fans. |

| E007 | Feedback Sensor Fault | Sensor or cable fault | Check sensor and cable. |

| E008 | Communication Fault | Communication bus fault | Check communication bus and connections. |

| E009 | Software Fault | Software corruption | Update software or contact ABB support. |

Symptoms of ABB DCS 500 failure

The ABB DCS500 is equipped with a self-diagnosis system that detects and records faults. These malfunctions can manifest themselves in different ways, indicating that there is a problem with the drive.

Here are some of the most common signs of an ABB DCS 500 malfunction:

- The drive does not turn on: This may indicate a problem with the power supply, connection cables, or the drive control board itself.

- The drive is not working properly: This can be manifested by the motor not turning or not turning at the correct speed or torque. This may indicate problems with the motor, feedback sensors, actuator, or software.

- A fault code appears on the display of the drive: Fault codes are unique codes assigned to each specific fault. These can be displayed on the drive display or via the configuration software. Fault codes can help you determine the cause of the fault and take appropriate action to correct it.

- Drive Alarm: The drive can alarm to warn of a malfunction. The alarm may be audible or visual, such as a flashing light.

Important: If you notice any of these symptoms, stop the drive immediately and take corrective action. Do not operate the drive if it is not working properly, as this may cause damage to the drive or motor.

Other signs of failure:

- Unusual noises or vibrations from the drive or engine

- The smell of burnt or overheated electrical equipment

- Unexpected stops or resets of the drive

- Damage to the drive housing

Important: If you notice any of these symptoms, stop the drive immediately and contact ABB support.

Troubleshooting

- Determine the fault code: If a fault code appears on the display of the drive, write it down. This code will help you determine the cause of the malfunction.

- Refer to the fault code table: ABB provides a fault code table that contains descriptions, possible causes and actions to be taken to eliminate faults. You can find this table in the user manual or on the ABB website.

- Follow the recommended actions: Follow the actions recommended in the trouble code table to eliminate the fault.

- Contact ABB Support: If you cannot rectify the fault yourself, contact ABB Support.

Remember: Troubleshooting the ABB DCS 500 can be a difficult task. If you are not sure of your abilities, it is recommended to consult a qualified professional.

ABB DCS 500 fault prevention

The ABB DCS 500 DC drive is a reliable and durable device, but like any mechanical or electrical equipment, it can fail. By following simple rules of preventive maintenance, you can significantly reduce the risk of malfunctions and extend the life of the drive.

Recommendations for preventing malfunctions of ABB DCS 500

- Inspect the drive regularly: Inspect the drive regularly for signs of damage or wear. This includes checking the housing, cables, connections and sensors.

- Keep the drive clean: Regularly clean the drive from dust and dirt. Dirt can accumulate in the vents and fans, which can cause the drive to overheat.

- Check the supply voltage: Make sure that the supply voltage of the drive corresponds to the nominal voltage. Incorrect supply voltage can damage the drive.

- Check connections: Make sure all connections to the drive are tight and secure. Loose connections can cause overheating and sparking.

- Calibrate the sensors: Calibrate the drive feedback sensors regularly. Incorrectly calibrated sensors can lead to incorrect operation of the actuator.

- Update the software: Make sure the drive has the latest software version installed. Software updates may contain bug fixes and performance improvements.

- Use original spare parts: When replacing any drive components, use only genuine ABB spare parts. The use of non-original spare parts can damage the drive.

- Contact a qualified technician: If you are unsure or have problems with the drive, contact a qualified ABB service technician.

By following these simple rules, you can significantly reduce the risk of DCS500 ABB malfunctions and extend the life of the drive.

Other tips for preventing malfunctions

- Do not overload the drive.

- Do not operate the drive in extreme environmental conditions.

- Do not operate the drive with damaged or worn components.

- Follow the ABB operation and maintenance instructions.

Remember: Prevention of malfunctions is always cheaper and easier than repairs. By following these tips, you can ensure that your ABB DCS 500 will work reliably for many years.

Conclusion

In the realm of industrial automation, the ABB DCS500 stands as a reliable and powerful DC drive system, but like any complex machinery, it can encounter issues that manifest as fault codes. Understanding these fault codes is crucial for maintaining the efficiency, reliability, and longevity of your drive system.

Thorough understanding of ABB DCS 500 fault codes and a commitment to timely intervention and regular maintenance will empower you to keep your industrial processes running seamlessly. This proactive approach not only enhances operational efficiency but also extends the lifespan of your drive system, ensuring that your investment in industrial automation delivers optimal returns.

The Eltra Trade website offers ABB DCS drives with worldwide delivery and our knowledgeable experts are always on hand to assist with your selection!