Baumer edge sensors

21.10.2019

SPECIFICATION:

Edge sensors are special devices that determine edges of the measured objects and perform other tasks of position measurement.

Such units make measurements according to optical principle, using a special optical signal. Generally, they use LED as a light source. They operate in various industrial areas, for example, in conveyors, in packaging, for the detection of welds, etc.

Such devices are indispensable in situations when quickly count and track the positions of a huge number of objects is needed.

The German company produces four main types of edge sensors:

- PosCon OXE7

- ZADM 023

- ParCon

- SCATEC

Each of these series is created to perform specialized positioning tasks. Let's take a closer look at them.

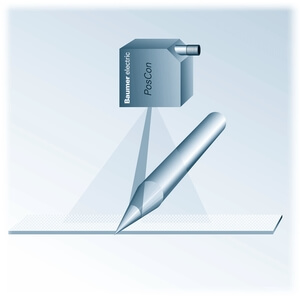

PosCon OXE7

The OXE7 series measures the width and gap. The main features of the series are:

- Lack of reflector

- Independence from run-out and lighting conditions

- Flexible mounting within ± 30 °

Units work without a reflector so the objects run-out has no effect on their sensing. Two optical receivers are installed in design. They obtain the returning signals. Such optical pulses reflect directly from the surface of the object and project into receivers. The equipment doesn`t need additional external processing devices or software.

PosCom sensors have the following major benefits:

- Wide working area

- Functions are controlled by a simple click on the button

- Ability to control using RS 485 interface

- Custom adjustable patterns for measuring

The devices can work with a side angle of up to 30°. It is possible to mount them in various positions without changes in the accuracy of results.

Products are delivered to the user with already-made factory calibration. Optically aligned axis qTarget and LED indicators ensure its stable operation.

The PosCon sensor category includes three main series:

- Poscon CM

- Poscon HM

- Poscon 3D

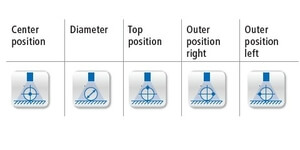

PosCon CM devices are designed to work with circular objects. Their main function is to determine the center, diameter, the highest point (top position) of the object. They  can also track outer points on the right or left side. Sensors work optimally with diameters from 30 to 130 mm. This category includes the OXC7-11170024 series.

can also track outer points on the right or left side. Sensors work optimally with diameters from 30 to 130 mm. This category includes the OXC7-11170024 series.

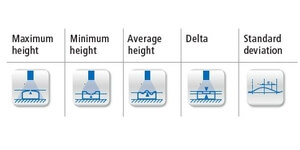

PosCon HM is a type of sensors for measuring values and changes in heights. They have a measurement accuracy of up to 2 μm and measure position using 5 indicators.

The following series belong to this type:

- OXH7-11149406

- OXH7-11161809

Such devices are easy to operate and there is no need of accurate positioning. Equipment measures the maximum, minimum and midpoints on objects as well as deviation parameters.

PosCon 3D is the most advanced type that specializes in measuring edges, width and gap of objects. The equipment operates with a wide variety of materials and in different conditions.

The series includes four models:

- OXE7.E15T-11148276

- OXE7.E15T-11177353

- OXE7.E25T-11111452

- OXE7.E25T-11174280

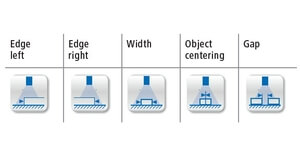

Sensors determine the extreme rightmost and leftmost edges, widths and gaps between objects. Presented sensors also perfectly perform centering tasks.

ZADM 023 line sensors

Sensors in this category have an extremely wide operating range (up to 875 mm). Their principle of work consists  of several actions. Optical signal (laser beam) comes from the built-in light source (pulsating infrared diode) to the reflective foil. Further, the diode array receives that signal.

of several actions. Optical signal (laser beam) comes from the built-in light source (pulsating infrared diode) to the reflective foil. Further, the diode array receives that signal.

The built-in microcontroller analyzes the received data and processes the result into analogue value. The length of the diode array and current distance to the measured surface determine the size of the measuring field.

ZADM sensors have a durable die-cast zinc housing with enclosure rating of IP67. Models have two output circuit options (PNP and NPN). Units operate with a resolution of up to 0.15 mm and signal frequency of 500 Hz.

The main advantages of the series are the ability of working with a wide measuring field and operating with transparent objects or foil. Models have three measuring modes: width, edge and centering. All products use Teach-in technology.

ParCon light-band sensors

Light-band sensors, like previous types, measure the width and edges of objects according to optical principle of operation. Pulsed infrared diode acts as a light source here. Outgoing optical signal is reflected by the opposite foil and then get to the diode array.

Its design forms a narrow working area from two sides. An object passes through such connection and blocks the path of beam. Then part of the light felling on the diode array get darker. The built-in microcontroller analyzes these parameters and generates an analogue signal.

The main benefits of ParCon technology are:

- Presence of parallel light beams

- Measurement with high frequency

- Optimal operation with rounded objects

- Measurement of very small objects

Unlike PosCon units, ParCon has a parallel measuring field in the form of a narrow strip with highs up to 24 mm. Light is not scattered over a distance in such design.

The sensors have a extremely high resolution (from 0.05 mm) and a large output frequency (up to 1800 Hz). This allows them to operate with very fast-moving and small objects.

Presented units also perform diameter monitoring. Mode switching (edge, center) by the user is performed via click on single button. Sensing system is housed in robust aluminum body with protection level IP67. Such design make it possible to use equipment in harsh conditions.

Scatec edge sensors and copy counters

The devices of this family are designed specifically for working with a looped conveyor belt. They are very popular in the packaging industry and in working with seamless objects.

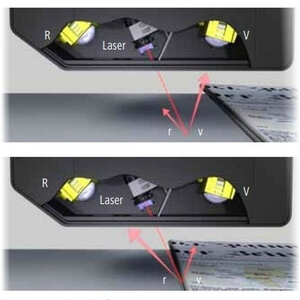

Units in this category operate according to the optical principle. A laser acts as a light signal. Two receivers (V and R) receive such pulses. This feature allows to accurately calculating the number of objects.

The following series belong the category of Baumer SCATEC:

- SCATEC-J

- SCATEC-2

- SCATEC-2 Box

- SCATEC-2 Gripper

- SCATEC-10

- SCATEC-15

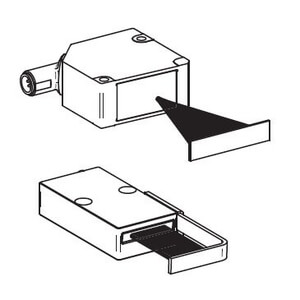

The company has created specialized models for different tasks. For example, SCATEC-2 BOX is designed to work in the packaging industry with the calculation of the boxes number in a conveyor belt. Such devices have a high response speed and can process up to 3 million copies per hour.

The products of the series use several modern technologies. ScaDiag diagnostic software records and saves all processing data. Plug & Play function provides quick commissioning.

Conclusion: The German company produces a wide variety of products for measuring edges. Sensors use different optical working principles and perform a wide range of tasks. Baumer is one of the market leaders in this segment thanks to its own developments and using of modern technologies in its products.

On our website Eltra-trade.com you will find all presented models. To check out stock availability and terms of delivery to your region, please contact our managers or leave a quick request.