Full overview of Burkert diaphragm sanitary and hygienic valves. The best choice for pharmaceutical industry.

26.11.2019

Burkert sanitary / hygienic valves are special units that meet the requirements of the medical, pharmaceutical and food industries.

Burkert sanitary / hygienic valves are special units that meet the requirements of the medical, pharmaceutical and food industries.

CONTENTS:

- What is sanitary valve?

- Burkert Pharmaceutical products

- Pneumatic diaphragm valves

- Electromotive and manual diaphragm valves

What is sanitary valve?

Sanitary valve is special equipment for working in industries with high demands on cleanliness and sterility.

Such sensors should not have crevices and cavities into which material can fall and accumulate various harmful bacteria. Working contact surfaces should be easy cleaning and mirror polished.

Sanitary valves operate in the following areas:

- Food and beverage processing

- Pharmaceutical process

- Biotechnology

- Medicine (hospitals etc.)

- Sterilizing equipment

- Dairy

- Cosmetics

The most important parts of the entire system are body and sealing. They must have appropriate certificates of health standards (medical or food).

Sealing and valve seats should be made of non-toxic materials and have mirror polished surfaces. The most often they are made of plastic, brass and different types of steel.

The user also should pay attention to equipment specifications. The important parameters to check are working pressure, diameter dimensions and operating temperature. Such primarily characteristics will help to determine whether the model is suitable for working with certain materials.

Burkert Pharmaceutical products

Burkert, like other hygienic valve manufacturers, highly appreciates the reliability and quality of its products. All of them have the necessary permits for working in hygienic conditions. This category includes certificates and requirements that are demanded by international organizations and national governments.

Pharma, sanitary and hygienic valves by Burkert comply with the following main global certifications:

- Level 2.2 Conformance Certification

- Level 3.1 Material Certification

- FDA compliance statement

- USP VI compliance statement

- CE Statement

- ATEX Certification

- Positive Material Identification (PMI)

- Ferrite Content Confirmation

- Surface Finish Profilometer Report

- EP Certificate

- Welding Certification and Boroscope Media

- CE Declarations

- 3A Certification

- CRN certificate

The products meet the requirements for both internal and external surfaces. All products are supported by relevant documentation for materials according to EN 10204 3.1.

The company carefully monitors the selection of materials for pharma valves producing. Only proven materials are selected.

Stainless steel for such valves consist a minimum of 10% of chromium. A chromium oxide film completely covers the entire surface and protects it from rust.

Products also provide a low content of ferrite. Electropolishing reduces roughness at 50%. For the manufacture of such details, high-precision modern CNCs are used. This kind of processing creates a high level of chromium content and thereby increase the corrosion resistance of the material.

Producer also manufactures a wide range of elastomers from EPDM, PTFE, FPM, silicone etc. They have full FDA and USP compliant certification. All materials are fully tested in the laboratories.

Pneumatic diaphragm valves

Presented valves use elastomeric diaphragm for media distribution control. They have a high level of flexibility and can be mounted in any position. Manufacturer produces types with pneumatic, electromotive and manual working principles.

Burkert produces the following series of pneumatic pharmaceutical valves:

- Type 2030

- Type 2031

- Type 2032

- Type 2033

- Type 2034

- Type 2063

- Type 2103

- Type 2104

- Type 2105

- Type 3230

- Type 8801

Type 2030 is a pneumatic 2-way valve that has a seamless plastic housing. Thanks to its features, it may operate with corrosive media.

Type 2031 this is a 2-way device with a hydroformed lightweight diaphragm valve body. It has a housing from stainless steel.

Type 2032 is a T-valve with zero dead volume metal body. The series is designed to control and manage sterile, ultrapure and abrasive fluids.

Type 2033 is a pneumatic 2-way tank bottom valve in plastic housing without welds. CIP / SIP or a sample port interfaces can also be connected to the equipment. Its diaphragm can be quickly removed and replaced.

Type 2034 is a GMP / SAP multifunctional system. It consists of pair 2/2 valves that are integrated in the assembly.

Type 2063 has actuator from stainless steel and intended for harsh environments. Stroke limiting function and various diaphragm materials are available.

Type 2103 is variable device with high bandwidth. The manufacturer produces models with both Element and stainless steel actuators. Those actuators are suitable for working with almost all control heads.

Type 2104 is a Zero Deadleg T-valve system with monoblock body without welds. It is perfect for sampling and draining purified water and injectable fluids.

Type 2105 this is tank bottom ELEMENT valve with separated chambers. Its design is similar to 2033. Structure may have Y-like outlet ends for better fluid distribution.

Type 3230 is a 2/2 plastic valve with compact size. Series is popular for operation in aggressive environments.

Type 8801 is on/off decentralized system that combine several units in one assembly. It can work with pressures up to 10 bar. Its actuator is made of polyphenylene sulfide or stainless steel.

Electromotive and manual diaphragm valves

Electromotive category is consisted of one series Type 3323 with metal or plastic housing. These devices use a stepper motor as an actuator. The stepper motor has high performance; therefore, electromotive units have a very fast opening/closing speed.

The series has diagnostic modes and drive control functions. It has DN 8 ... 50 port of mechanical connections. The models operate with industrial protocols Ethernet / IP, Modbus TCP and PROFINET.

Manual types are valves controlled by handwheel/handlever or other manual operators. They are best suited for channel opening/closing.

Burkert releases 4 series of manually operated valves:

- Type 3232

- Type 3233

- Type 3234

- Type 3235

Type 3232 is unit with TVB3G body design that operates with true union and solvent socket ends. It has a single variant of connection DN4. Actuator and housing are made of PPS.

Type 3233 is a 2/2 -way manually operated diaphragm valve with hydroformed tube body. This series has weld or clamp ends ¼ ”- ½” according to ASME BPE standard. It has very light thermal mass and steam rate savings of up to 53.8%.

Type 3234 is a manual monoblock T valve. Device housing is made of stainless steel, which is certified EN 10204 3.1. It also has a Zero Deadleg diaphragm in its design.

Type 3235 is a valve with wide port connection options (from DN15 to DN50). It has Block body design. Diaphragms are made of PTFE, EPDM, FKM and Gylon® materials are available.

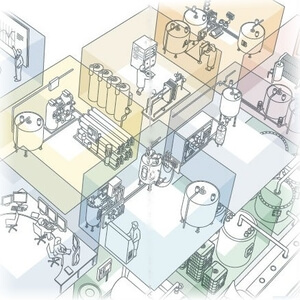

In addition to membrane pharma valves, the company also produces a wide range of other types: t-valves, multiport robolux systems, tank bottom and bellows valves. They are also operated in pumps, pipelines, and steam, fluid and gases distribution systems.

Conclusion: The Company with high responsibility makes valves involved in the health and food industry. Products always have all necessary certificates for their working areas. Careful control is carried out already at the stage of selection of material and its testing in laboratories. Therefore, Burkert valves are the products the customer can fully trust!

On eltra-trade.com you can find various Burkert valves. To find out the right model please consult with our managers! Call now!