Endress+Hauser Promag 50 Fault Codes: Troubleshooting Guide

31.05.2024

Precision and dependability are critical components in the field of industrial automation. An essential tool for measuring the precise flow of conductive liquids in a variety of sectors is the flowmeter endress hauser promag. However, like any sophisticated device, it is not immune to faults and errors. Understanding these endress hauser promag 50 fault codes is essential for maintaining uninterrupted production and ensuring the efficiency of operations.

Precision and dependability are critical components in the field of industrial automation. An essential tool for measuring the precise flow of conductive liquids in a variety of sectors is the flowmeter endress hauser promag. However, like any sophisticated device, it is not immune to faults and errors. Understanding these endress hauser promag 50 fault codes is essential for maintaining uninterrupted production and ensuring the efficiency of operations.

Fault codes generated by the Promag 50 serve as a diagnostic tool, alerting operators to potential issues that may compromise the accuracy of measurements or the functionality of the device. These codes provide detailed information about the nature of the fault, allowing for quick identification and resolution.

Anticipating and addressing these errors before they escalate is crucial. Downtime caused by unresolved faults can lead to significant production delays, increased operational costs, and even compromised product quality. By being proactive in understanding and managing fault codes, you can enhance the reliability of your endress promag 50 and maintain smooth production processes.

Understanding the Promag 50

An electromagnetic flow meter designed to gauge the flow rate of conductive liquids is the endress hauser promag 50. Its lack of moving parts, in contrast to mechanical flow meters, lowers wear and tear and increases dependability. Utilizing Faraday's law of electromagnetic induction, the apparatus measures the induced voltage to ascertain the flow rate by applying a magnetic field to the liquid in motion.

Key Components and How It Works

- Sensor: The heart of the Promag 50 is its sensor, which generates a magnetic field across the pipe. As the conductive liquid passes through this field, it induces a voltage proportional to the flow velocity.

- Transmitter: The transmitter processes the voltage signal from the sensor and converts it into a flow rate reading. It also handles configuration, display, and communication functions.

- Electrodes: These electrodes are positioned within the flow tube and use the voltage that the flowing liquid induces to measure the flow rate.

- Flow Tube: The flow tube is the section of the pipe where the measurement takes place. It is lined with a non-conductive material to ensure accurate voltage detection.

Applications

The endress promag 50 is utilized across various industries for its precision and reliability. Some of its common applications include:

- Water and Wastewater Treatment: Ensures accurate measurement of water flow for treatment processes, billing, and regulatory compliance.

- Chemical Processing: Measures the flow of various chemicals, ensuring precise control of blending and reaction processes.

- Food and Beverage Industry: Monitors the flow of ingredients and products to maintain quality and consistency in production.

Advantages of Electromagnetic Flow Meters

- Non-Intrusive Measurement: Since there are no moving parts in contact with the fluid, there is minimal pressure drop and no risk of contamination.

- Low Maintenance: The absence of mechanical components reduces the need for frequent maintenance and repairs.

- Wide Range of Applications: Suitable for a diverse array of fluids, including corrosive and viscous liquids, making it highly versatile.

Common Fault Codes

The endress hauser promag 50 electromagnetic flow meter is equipped with a comprehensive fault diagnostic system that generates fault codes to alert users to specific problems. Understanding these fault codes and their meanings is essential for troubleshooting and ensuring the continued accuracy and reliability of the flow meter.

The Promag 50 fault codes are designed to provide detailed information about the nature of the issue, ranging from minor configuration errors to critical system failures. Here, we will discuss some of the most common fault codes encountered with the Promag 50 and provide insights into their causes and potential solutions.

Fault codes list

| Error Code | Description | Possible Causes | Solution |

| F01 | Sensor error | Damaged sensor, incorrect sensor connection | Check sensor connection, replace sensor |

| F02 | Measuring circuit error | Interference in sensor cable, incorrect grounding | Check sensor cable for damage, ensure sensor is properly grounded |

| F03 | Electronics error | Damaged flowmeter electronics | Contact Endress+Hauser service center |

| F04 | Range exceeded | Flow rate exceeds flowmeter range | Install a larger range flowmeter or reduce flow rate |

| F05 | No signal from sensor | Sensor is not connected or damaged | Check sensor connection, replace sensor |

| F06 | Temperature error | Incorrect temperature measurement | Check temperature sensor, replace sensor |

| F07 | Configuration error | Flowmeter is configured incorrectly | Check flowmeter configuration, reset to factory defaults |

| F08 | Software error | Flowmeter software is corrupted | Update flowmeter software |

| F09 | Communication error | Problem communicating with flowmeter | Check communication cable, restart flowmeter |

Promag Error Codes: Detailed Explanation and Troubleshooting

F01: Sensor Error

Cause:

- Damaged sensor

- Incorrect sensor connection

Solution:

- Check sensor connection: Ensure the sensor is properly connected to the flowmeter and the cable is not damaged.

- Inspect sensor: Check the sensor for any visible signs of damage, such as cracks, dents, or corrosion.

- Replace sensor: If the sensor is damaged, replace it with a new one from Endress+Hauser.

F02: Measuring Circuit Error

Cause:

- Interference in sensor cable

- Incorrect grounding

Solution:

- Check sensor cable: Inspect the sensor cable for any signs of damage, such as cuts, kinks, or frayed wires.

- Verify grounding: Ensure the sensor is properly grounded to eliminate electrical interference.

- Shield cable: If the cable is exposed to electromagnetic interference, consider using a shielded cable to reduce interference.

F03: Electronics Error

Cause: Damaged flowmeter electronics

Solution:

- Reset flowmeter: Try resetting the flowmeter to factory defaults. Refer to the user manual for instructions.

- Contact Endress+Hauser support: If resetting the flowmeter doesn't resolve the issue, contact Endress+Hauser support for further assistance.

F04: Range Exceeded

Cause: Flow rate exceeds the flowmeter's measurement range

Solution:

- Install larger range flowmeter: If the flow rate consistently exceeds the flowmeter's range, install a flowmeter with a larger measurement range.

- Reduce flow rate: If possible, adjust the process to reduce the flow rate to within the flowmeter's range.

F05: No Signal from Sensor

Cause: Sensor is not connected or damaged

Solution:

- Verify sensor connection: Ensure the sensor is properly connected to the flowmeter and the cable is not damaged.

- Check sensor power: If the sensor requires external power, ensure it is receiving power.

- Replace sensor: If the sensor is still not detected, replace it with a new one from Endress+Hauser.

F06: Temperature Error

Cause: Incorrect temperature measurement

Solution:

- Inspect temperature sensor: Check the temperature sensor for any signs of damage or contamination.

- Calibrate temperature sensor: Calibrate the temperature sensor according to the user manual.

- Replace temperature sensor: If the sensor is damaged or cannot be calibrated, replace it with a new one from Endress+Hauser.

F07: Configuration Error

Cause: Flowmeter is configured incorrectly

Solution:

- Check flowmeter configuration: Review the flowmeter's configuration settings to ensure they are correct for the application.

- Reset to factory defaults: If the configuration is complex, consider resetting the flowmeter to factory defaults and reconfiguring it.

- Consult user manual: Refer to the user manual for detailed configuration instructions.

F08: Software Error

Cause: Flowmeter software is corrupted

Solution:

- Update flowmeter software: Download and install the latest software update from Endress+Hauser.

- Contact Endress+Hauser support: If the software update fails or doesn't resolve the issue, contact Endress+Hauser support for further assistance.

F09: Communication Error

Cause: Problem communicating with flowmeter

Solution:

- Check communication cable: Ensure the communication cable is properly connected to both the flowmeter and the communication device.

- Verify communication settings: Check the communication settings on both the flowmeter and the communication device to ensure they match.

- Try different communication method: If using a serial connection, try using a different communication method, such as Ethernet or Modbus.

Best Practices for Avoiding Faults

Ensuring the reliable operation of the flowmeter endress hauser promag 50 requires a proactive approach. By implementing best practices for maintenance and operation, you can minimize the occurrence of faults and enhance the overall performance and longevity of your device. Here are some essential strategies to help you avoid common faults with the Promag 50.

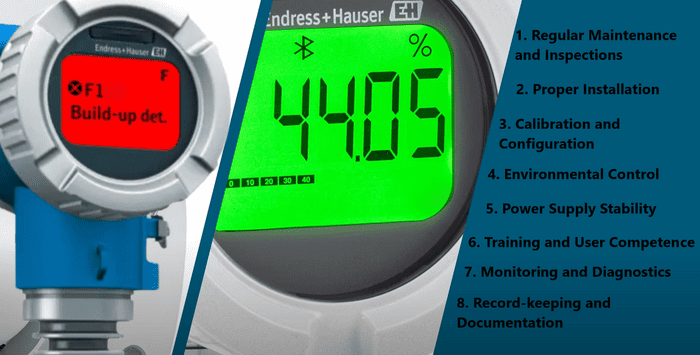

1. Regular Maintenance and Inspections

Routine maintenance is crucial for keeping the flow meter promag 50 in optimal working condition. Schedule regular inspections to check for any signs of wear, damage, or obstructions in the flow path. Cleaning the flow sensor and electrodes can prevent build-up that might interfere with accurate measurements.

2. Proper Installation

Ensure that the Promag 50 is installed according to the manufacturer’s guidelines. Correct installation includes proper alignment, securing the device to avoid vibrations, and ensuring that the flow tube is free from any obstructions. Using the correct pipe dimensions and materials also helps maintain accurate readings and prevent faults.

3. Calibration and Configuration

Regular endress hauser flow meter calibration is necessary to maintain the accuracy of the Promag 50. Follow the calibration procedures outlined in the user manual and ensure that all configuration settings match the requirements of your specific application. Misconfigurations are a common cause of faults, so double-checking these settings can prevent errors.

4. Environmental Control

Monitor the operating environment of the flow meter promag 50. Extreme temperatures, high humidity, and corrosive substances can affect the performance and lifespan of the flow meter. Ensure the device is operating within the recommended environmental conditions and protect it from harsh elements.

5. Power Supply Stability

A stable and adequate power supply is essential for the Promag 50. Use surge protectors to safeguard against power spikes and ensure that the power source meets the device’s voltage and current requirements. Unstable power can lead to frequent power supply errors and other malfunctions.

6. Training and User Competence

Ensure that all personnel operating the Promag 50 are properly trained and understand the device’s functions and endress hauser promag 50 fault codes. Educated users are more likely to follow best practices and can quickly identify and resolve issues before they escalate.

7. Monitoring and Diagnostics

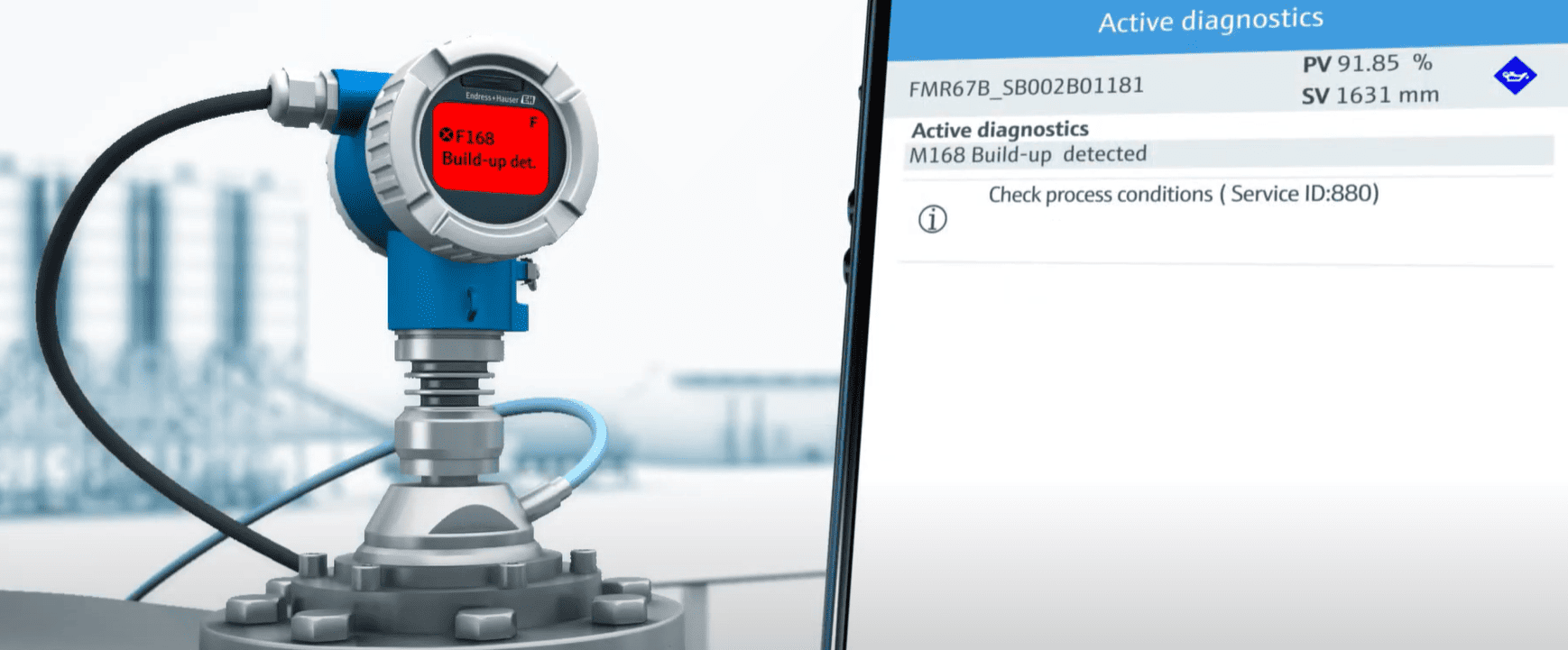

Utilize the Promag 50’s built-in diagnostic tools and any available external diagnostic software to continuously monitor the device’s performance. Early detection of anomalies allows for timely interventions, preventing minor issues from developing into significant faults.

8. Record-keeping and Documentation

Keep thorough records of all maintenance operations,endress hauser flow meter calibration, and any issues or fault codes encountered. This documentation can help identify patterns or recurring problems, providing valuable insights for preventative measures and improving troubleshooting efficiency.

9. Firmware and Software Updates

Keep the Promag 50’s firmware and any associated software up to date. Updates often include bug fixes, performance improvements, and new features that can enhance the device’s functionality and reliability. Regularly check for updates from Endress+Hauser and apply them as needed.

10. Adhering to Manufacturer’s Guidelines

Always refer to the manufacturer’s guidelines and recommendations for operating and maintaining the flow meter promag 50. These guidelines are designed to optimize performance and prevent faults, ensuring the device operates as intended.

Conclusion

Managing fault codes in the endress and hauser promag 50 is crucial for maintaining the efficiency and reliability of your industrial operations. Diagnostic fault codes list act as an early warning system, highlighting potential issues that could affect the performance of your flow meter. By understanding common endress hauser promag 50 fault codes and their causes, you can quickly diagnose and address problems before they lead to significant downtime or costly repairs.

A proactive approach to managing the Endress+Hauser Promag 50 involves a combination of proper maintenance, user education, and leveraging diagnostic tools. By following these strategies, you can ensure that your flow meter remains accurate, reliable, and efficient, contributing to the overall success of your industrial automation processes.