Endress+Hauser Flow Meters

Promag P 300

- Flow measurement range: 0.002-100 m3/h

- Operating temperature: -20...+150 °C

- Operating pressure: 1-6 bar

- Weight: 0.9 kg

Endress+Hauser Promag P 10

- Flow measurement range: 4 dm³/min - 9600 m³/h

- Temperature range: -20 °C - +150 °C

- Maximum working pressure: PN40

- Standard lining materials: PTFE, PFA

- Standard electrode materials: 1.4435/316L

Endress Hauser Promag P 10 Electromagnetic Flowmeter

Endress+Hauser Promag P 10

- Easy to use.

- Suitable for aggressive liquids.

- PTFE or PFA lining for extra resistance.

- Optionally available with display and touch screen.

- Communication: HART or Modbus RS485.

Promag W 10 Flowmeter

- Measurement range: 0.5-263000 m³/h

- Measurement accuracy: ±0.5%, ±0.2% (with HART)

- Working environment temperature: 0-80 °C

- Maximum working pressure: 16 bar

- Weight: 3.2 kg

Vortex flowmeter Inline version Prowirl F 200, 7F2C40, DN40 1 1/2

Accuracy flowmeter:

Volumetric flow rate of liquids: ±0,75%

Mass flow rate of liquids: ±0,85%

Volumetric flow rate of gases: ±1,00%

Mass flow rate of gases: ±1,70%

Vortex flowmeter

- Measuring range: 0.1 kg/s - 400 kg/s (0.22 lb/s - 882 lb/s)

- Accuracy: ±0.75% of the reading

- Protection class: IP67

- Operating temperature: -200°C…+400°C/-328°F…+750°F

Endress+Hauser Vortex flowmeter Inline version

- Power supply voltage: 11...45 V DC

- Power consumption: ≤ 4.5 W

- Degree of protection: IP66/IP67

- Installation height: up to 2000 m (6562 ft)

Endress+Hauser 7R2CRM flow transmitter

- Housing: Aluminum, coated

- Measuring tube: 316L

- Sensor seal: graphite

- Membrane: 316L

Endress+Hauser 8F1B25 electromagnetic flowmeter

- Measuring range: 0.01 ... 10 m/s (0.04 ... 32.8 ft/s)

- Maximum error: ±0.5% of the measured value

- Viscosity: Up to 200 mPa-s (cP)

- Degree of protection: IP67

Endress+Hauser Coriolis flowmeter

- Body material: coated aluminum

- Mounting type: flanged

- Degree of protection: IP67

- Temperature range: -40...+80 °C

- Weight: 2.5 kg

Endress+Hauser Picomag electromagnetic flowmeter

- Media temperature: -10 to 70°C

- Maximum pressure of the medium: 16 bar

- Pipeline diameter: 15 to 200 mm

- Weight: from 0.2 to 1.2 kg

Endress+Hauser FTC262-EA12D1 Capacitance Point level detection

- A simple and economical way to control the level in bulk materials.

- It is resistant to aggressive media and heavy deposits.

- It is easy to install and start up and does not require calibration.

- An attractive substitute for paddle sensors.

- Max. measurement error: Flow rate: +/- 0.8% or +/- 0.1% of

- Measuring range: up to 750 l/min

- Max. process pressure: 16 bar

Proline Promag D 10 is highly cost-effective wafer flowmeter with easy-to-use operation concept.

- Flow Rate: 3.6 to 601860 l/h

- Error: 0.5%

- Outlet Diameter: DN 40 F

- low Rate (l/min): 0.06 to 10031

- DN 50

- IP67

- Rate 3.42 to 601860 L/h

- Accuracy: 0.5%

Operating temperature: -20 to +150°C (standard)

Application: For chemical and industrial processes with corrosive liquids and high operating temperatures.

- 4 dmВі/min to 9600 mВі/h (1 gal/min to 44 000 gal/min)

- 20 to +150 В°C (4 to +302 В°F)

- PN 40, Class 300, 20K

- Wetted materials: Liner: PFA; PTFE/ Electrodes: 1.4435 (316L); Alloy C22, 2.4602 (UNS N06022); Tantalum; Platinum; Titanium

- DN 25 - DN 2400

- 24 to 230 V

- -20 to 50°C

- IP68

- 9 dmВі/min to 162 000 mВі/h (2.5 gal/min to 100 000 gal/min)

- PN 40, Class 300, 20K

- Max.error: Volume flow (standard): В±0.5 % o.r. В± 1 mm/s (0.04 in/s)

- range: 9 dmВі/min to 162 000 mВі/h (2.5 gal/min to 100 000 gal/min)

- Max. pressure: PN 40, Class 300, 20K

The E&H Flow Meter is a device that determines the volume flow or mass flow of a substance, that is, the amount of a substance passing through a flow stream, for example, the cross section of a pipeline per unit time.

Endress and Hauser Flow Meter Types

Endress Hauser Coriolis Flow Meter

The action is based on the Coriolis effect: U-shaped tubes are subject to vibrations during movement, and vibrational vibrations, in turn, cause the substance to twist. The magnitude of the phase shift depends on the lot flow rate of the fluid or vapor. The flow rate is measured taking into account the resulting twist angle. Most often, such currentmeters are used for aqua media, including paints, varnishes, liquid polymers.

Advantages of mass flow meters:

- Mass flow is measured directly.

- Precipitation or contamination dissolved in the liquid does not affect the measurement results.

- There are no obstacles in the internal section, the system works stably.

- There are no obstacles in the internal section, the system works stably.

The main EH Series: Proline Promass, Dosimass, Proline Cubemass

Variable differential pressure flowmeters

The principle of operation of Endress Hauser Deltabar is based on the measurement of the pressure drop that occurs when a liquid or gas flow passes through a narrowing device (washer, nozzle). At this point, the flow rate changes, and the pressure increases. Measurements at the point of passage of an obstacle are made applying aincrement pressure sensor.

Excellences: there are no moving parts in the device.

Endress Hauser Electromagnetic Flow Meter

An electromotive force is generated by the action of water or other conductive liquid passing through a magnetic field. It turns out that the liquid flows between the poles of the magnet, creating an EMF, and the device fixes the voltage between the 2 electrodes, thereby measuring the size of the flow. This device works with minimal errors, provided that purified liquids are transported and does not slow down the flow in any way.

The principle of operation of electromagnetic flowmeters

It is based on the interaction of a moving electrically conductive liquid with a magnetic domain. When a fluid moves in a magnetic area an emf arises, as in a conductor moving in a magnetical range. This EMF is proportional to the flux evaluate, and the stream appreciate can be determined from the flow rate.

Advantages:

- There are no moving and stationary parts in the cross section, which allows you to keep the speed of fluid transportation.

- Measurements can be made in a large dynamic range.

E&H Electromagnetic Flow Meter series includes: Proline Promag, Dosimag, Picomag

Tachometric flow meters

The main measuring element is the impeller or turbine (located perpendicular or parallel to the flow, respectively). The process measures the speed of rotation and the number of revolutions made in the stream.

Advantages:

- Suitable for liquid, steam and gas flow dimension.

- Easily mounted on pipelines of small diameters and are often used in domestic conditions.

- Operates without power supply, no electrical connection required.

E&H ultrasonic flow meter

Stream meters of this type are supplemented with ultrasonic signal transmitters. The speed of the signal from the transmitter to the receiver will change every time the fluid moves. If the ultrasonic signal goes in the direction of the flow, then the time decreases, if it goes against it, it increases. By the difference in the time of signal passage along the flow and against it, the volume flow velocity of the dip is calculated. As a rule, such devices are equipped with an analog output and a microprocessor control unit, and all displayed data is displayed on an LED display.

Advantages:

- Vibration and shock resistance.

- Stable, durable housing.

- Suitable for refinery and cooling applications.

- Perform flow measurements of water and liquids similar to water in physical properties.

- Work in the average dynamic range of measurements.

- Can be mounted on pipelines of large diameters.

Endress Houser offers Clamp-on and In-line ultrasonic flow meters: Proline Prosonic Flow, Teqwave

Endress and Hauser Vortex Flow Meter

In Proline Prowirl flowmeters, the frequency of oscillations that occur in a gas or liquid flow at the moment of bypassing obstacles is measured. The flow around leads to the formation of vortices (in fact, this is why this type of device got its name), and the magnitude of the change in vortices allows you to calculate the flow strength.

Advantages:

- Suitable for measurement the flow of gases, industrial air.

- There are no moving parts in the design.

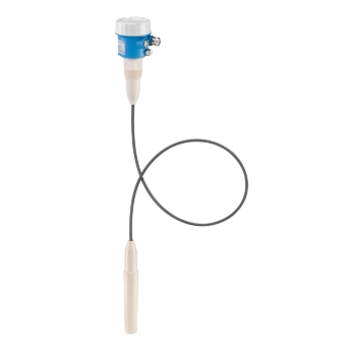

Endress Hauser Gas Flow Meter

Thermal mass flow meters from EH are designed for direct mass flow measurement of compressed air, gases and water-based liquids.

This flowmeter consists of a signal converter and a probe with temperature sensors (RTDs) located at the end of the probe. One sensor measures the operating temperature, and the other one heats up to a certain temperature above the operating temperature. As the flow increases, the heated sensor cools down.

Use of flow Meters

The flowmeters are intended for use in the heat and power, chemical, food and other industries as a means of commercial accounting and technical control of liquids in various technological processes.

You can buy any of Endress Hauser Flow Meter at the best price from our company.