How Do Photoelectric Sensors Work?

16.03.2023

In industry, specialized devices such as photoelectric sensors are actively used, which allow the most accurate detection of an incoming object without the need for physical contact. Such sensors are mainly used in the installation of various industrial equipment. However, they are of different types and differ in the principles of functioning. Today we will discuss what photoelectric sensors are, how they work, where they are used, and their main advantages and disadvantages.

What are Photoelectric Sensors?

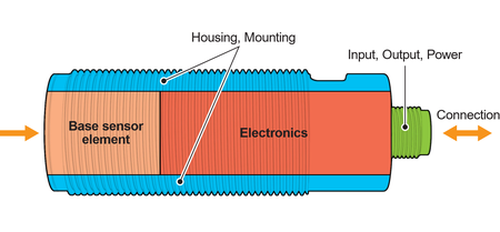

The photoelectric sensor is an optical sensor that consists of a light source, a light receiver, and a signal output and control circuit. They can detect the presence of objects and sometimes the state of the surface.

The photoelectric sensor working when the emitted light is interrupted by an object in the immediate vicinity, the light receiver detects this change and switches the sensor output on or off. Some proximity sensors can even determine the distance to an object.

Depending on the method of operation used, photoelectric sensors are usually divided into four groups:

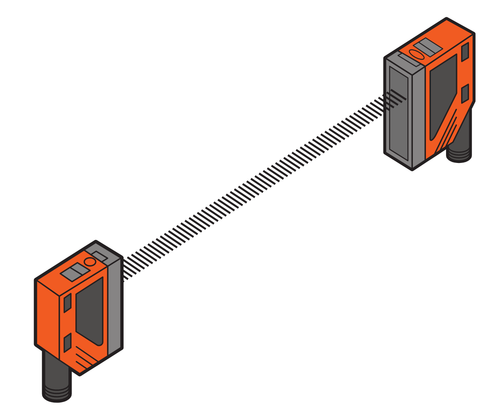

- Working on the principle of beam crossing. In this case, the emitter and the receiver working with it in pairs have two separate housings, since this is required by the operating technology. Two devices are installed opposite each other, and when interacting, the emitter sends a beam that is perceived by the receiver. If any object crosses this beam, the device immediately sends a corresponding signal.

- Sensors with the principle of reflection from the reflector. Such devices are characterized by the fact that they have an emitter and a receiver located in the same housing. In addition to this unit, a special reflector is also used, which is installed opposite the device. During operation, the device sends a beam, it is reflected from the reflector and perceived by the receiver. A special polarizing filter allows you to adjust the operation of the equipment so that the device perceives only the reflection from the reflector and nothing more.

- Devices with the reflection of light from an object. For these units, the receiver and the emitter accompanying it are also located in the same housing. In this case, the work is structured in such a way that the reflector is not needed since various objects play its role - the beam is reflected from them, hits the receiver, and the sensor sends the desired signal.

- Sensors with a fixed reflection. In fact, this is an improved version of the previous version of the equipment. Devices work on the same principle, but they more sensitively capture and determine the state of the object. For example, with the help of such sensors, it is possible to detect swollen packages on the line or a bag that is not completely filled.

How do Photoelectric Sensors Work?

The photoelectric sensing technology is that when light hits the sensor unobstructed, it will be activated. And when this light is interrupted by a barrier (a person, a workpiece, a machine part), the sensor is deactivated. Optical sensors are non-contact, that is, there is no mechanical contact with the observed object (activator).

In most cases, to increase noise immunity, light is not used in the usual spectrum, but the radiation of a laser light source (usually red). Such a source is easy to manufacture, and the radiation is easily focused into a thin beam. And due to the fact that the radiation is in the visible part of the range, the position of the sensor is easy to adjust in space.

On identify the photo sensors, in most cases, there is a “Dark On/Light On” switch. What does it mean? It inverts the logic of work. With “Dark On”, the sensor is activated when no light enters its input, that is, darkness at the input. When light hits, the sensor is deactivated, that is, its output returns to its normal state. In the “Light On” mode, the sensor is activated when its input is illuminated.

Applications of Photoelectric Sensors

Photoelectric sensors are widely used in many industries. Some industries are listed below:

- Food industry. Production and packaging lines in the food and beverage industry also use photoelectric sensors. For example, a bottle capping machine must be equipped with a system to properly align and orient each bottle cap. If there are any errors in positioning, photoelectric sensors can help detect them to keep the plant running smoothly.

- Automotive industry. When a car body is created, each component must pass through the production line in a reliable sequence. Each part must slow down and stop in front of the appropriate station at the exact time so that it can be welded or otherwise machined without any errors. Photoelectric sensors can determine when the corresponding station is nearby to stop the line and process the component.

- Engineering. For large machines that need to run in perfect synchronization, photoelectric sensors can provide a good level of reliability. In such cases, there is no margin for error, and photoelectric sensors can help you place and remove machine components efficiently.

- Doors and gates. Automatic doors and gates, such as in buses, trains, elevators, garages, etc., must have reliable sensor technology so that they open and close at the right time. The entire area in front of the door must be under the detection zone for automatic doors to work properly. Photoelectric sensors combined with infrared scanners can detect approaching people or vehicles.

- Material handling. In warehouses with full or partial automation, photoelectric sensors allow you to effectively track objects in the warehouse, help automate the storage and stacking of goods, and help you keep inventory.

- Pharmaceutical industry. Pharmaceutical industry applications such as drug packaging also use photoelectric sensors. During packaging, sensors can be used to avoid inconsistencies such as empty packaging due to no pills on the line, etc.

Advantages and Disadvantages of Photoelectric Sensors

Below we will explore the advantages of photoelectric sensors:

- They feel all kinds of materials.

- Has a longer service life.

- They have a long-range and are very reliable.

- Very fast response time.

- It's less costly.

- The scattering photoelectric sensor detects small objects, including the detection of colored marks and labels.

- The retroreflective type can detect transparent objects.

- Thru-beam type can detect long distances and is resistant to a dirty environment.

And now let's look at the disadvantages of photoelectric sensors:

- Lenses get dirty over time.

- The range is affected by the color and reflectivity of the target.

- A thru-beam requires a transmitter and a receiver at two different locations.

Eltra Trade s.r.o. supplies a lot of photoelectric sensors brands. We can offer the best prices for Sick, Peppeerl+Fuchs, Baumer, IFM Photoelectric sensors and many others.