How does a vortex flow meter work?

06.10.2019

Vortex flowmeter is a transducer that determines the flow rate of a substance in a pipe section by analyzing a vortex street (von Kármán vortex).

CONTENTS:

- Vortex shedding flow meter working principle

- Main types

- Advantages and disadvantages of vortex flowmeters

Vortex shedding flow meter working principle

The operation of such flow meters is based on the analysis of vortex shedding that appearing when a stream flows through an obstacle. This phenomenon is also called the Karman vortex street, in honor of its discoverer. Various eddies will form regardless of the shape of the body through which the stream flows.

The easiest way to imagine this effect is the example of a flagpole and a flag. Air acts as a stream, and a flagpole as a solid body (obstruction). When the stream flows around the flagpole, vortices are formed. It can be seen on the flag canvas waving.

Streamlined bodies can be in a variety of sizes and shapes, but more often as cylindrical objects. Such barrier is mounted perpendicular to the flow direction. The measurement of the transducers is primarily based on determining the frequency of the vortex waves.

That principle is described by the formula:

f = Sr * v/d

Sr - Strouhal number

v - flow velocity

d- width of bluff body

The Strouhal number is a dimensionless quantity that depends on oscillating flow parameters (frequency of vortex shedding, flow distance and velocity).

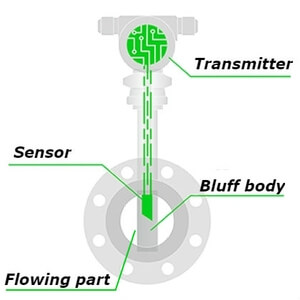

Vortex flowmeters design

All devices that related to the presented type have similar basic elements. Vortex flowmeter consists of following parts:

- Flowing part

- Bluff body

- Sensors

- Transmitter

Flowing part. This section is inside the flowmeter, which is most often mounted directly in the pipeline.

Bluff body. It consists of a solid material and is installed perpendicular to the flow. That part act like a barrier. It can be in various shape (cylinder, square, triangle, polyhedron, etc.)

Sensors are installed for the analysis of generated turbulence.

Transmitter. That device analyzes the receiving results and transform them into electrical signal.

In addition to the main elements in the vortex flow meter system, various additional devices can be installed, for example, a calculator or a normalizing converter, etc.

Main types

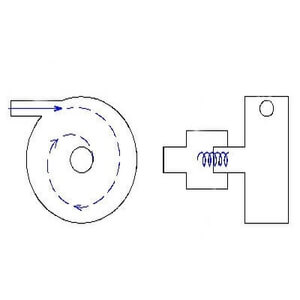

There are two types of the most commonly used vortex flowmeters:

- With a streamlined motionless body

- With a spiral vortex funnel

With a streamlined motionless body. In this type, the flow moving through a bluff body and alternately forms vortex shedding on both sides. It causes pressure surges and speed changes, which are analyzed by sensors.

With spiral vortex funnel. In such devices, vortex waves are generated with the help of special devices and already in the form of vortex street get into the flow part. Measurements are also made by analyzing changes in speed and pressure like in the previous type.

Advantages and disadvantages of vortex flowmeters

Presented devices work in different industrial applications. Like all measuring devices, they have their strengths and weaknesses.

The advantages of vortex flowmeters:

- Lack of moving parts

- High accuracy

- Wide range of working temperatures

- Good repeatability of results

- Low pollution level

The disadvantages of vortex flowmeters:

- The need for high flow rates

- There should be straight pipe sections in front of the converter

- Reducing of pressure in a stream

- Inability to work with a cross section of more than 300 mm

- External vibration influence on the result

Conclusion: presented flow converters gained wide popularity in all sectors of production. This is achieved due to the simplicity and accuracy of such devices. However, you should avoid installing them in places where various mechanical forces can act on the device, as well as in pipes with a cross section of more than 300 mm.

On our website eltra-trade.com you can find equipment of presented type.