Namur Sensor Pepperl Fuchs: the main advantages

17.01.2024

Pepperl Fuchs' NAMUR sensors, which provide a special blend of safety, dependability, and flexibility, are crucial parts of the industrial automation environment. One of the key advantages of NAMUR sensors is their non-contact detection, which minimizes wear and tear, resulting in longer service life and lower maintenance costs. We will reveal the key benefits of utilizing Pepperl Fuchs NAMUR sensors, highlighting the reasons they are a dependable option for numerous sectors in need of dependable and adaptable automation solutions.

Namur Sensor Pepperl Fuchs Explained

Pepperl Fuchs is a leading name in the industrial automation industry, known for its commitment to innovation, quality, and safety. The brand has a rich history dating back to 1945 and has become synonymous with reliable sensor technology. Their NAMUR sensors reflect the company's dedication to producing high-quality products that meet the strictest safety standards.

The term "NAMUR" is derived from the German association for standardization in measurement and control technology, Normenarbeitsgemeinschaft für Mess- und Regeltechnik (NAMUR). This organization sets the safety and compatibility standards for sensors used in explosive atmospheres, which is why сhemical processing, oil and gas, and pharmaceuticals are among the industries that frequently use NAMUR sensors.

Namur sensor pepperl fuchs engineered to excel in hazardous environments. They are constructed with robust materials and advanced technology, ensuring they withstand harsh conditions like extreme temperatures, vibrations, and corrosive chemicals. This durability and reliability are why the brand is a top choice for industries that require consistent performance and compliance with safety regulations.

Essential Features of Pepperl Fuchs' NAMUR Sensors

NAMUR sensors play a critical role in industrial automation, offering unique features that make them indispensable in various industries. Their key attributes contribute to efficient operations, safety, and reduced maintenance costs.

The Technical Features of NAMUR Sensors

NAMUR sensors are designed to meet the rigorous demands of industrial automation and hazardous environments. Their technical characteristics are tailored to ensure safety, reliability, and versatility.

Table of initial technical characteristics of Namur Pepperl Fuchs sensors

| Feature | Value |

| Operating temperature range | -40°C to +85°C |

| IP protection class | IP67 |

| Cable type | M12 |

| Maximum cable length | 2 m |

| Supply voltage | 10...30 V DC |

| Current consumption | < 100 mA |

| Response time | < 1 ms |

| Hysteresis | < 2% |

| Output type | PNP or NPN |

| Can be used in hazardous areas | Yes, with ATEX and IECEx certificates |

| Housing material | Stainless steel or brass |

| Connection type | M12 connector |

| Operating frequency | 1kHz - 10kHz |

| Sensitivity | < 10 mm |

| Sensor size | M8, M12, M18, M30 |

| Mounting type | Threaded, flange, bracket |

These technical characteristics highlight the versatility and robustness of NAMUR sensors, making them an excellent choice for a wide range of industrial automation applications. The excellent safety, dependability, and adaptability of Pepperl Fuchs' NAMUR sensors enable them to satisfy the needs of contemporary industrial processes.

Types Namur Sensor Pepperl Fuchs

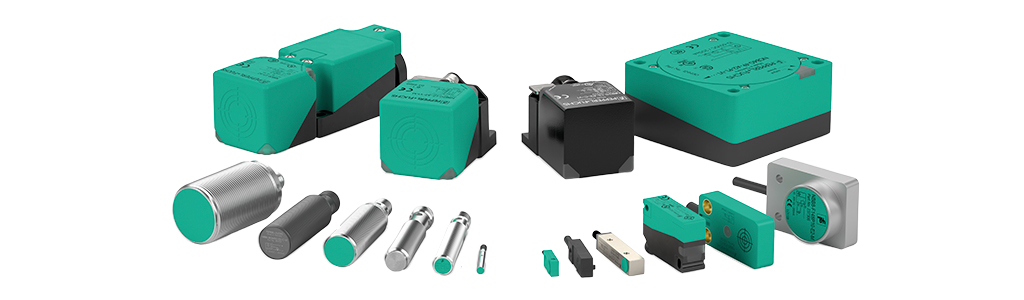

Pepperl Fuchs offers a wide range of Namur sensors, which can be classified into several categories

1. By type of detection

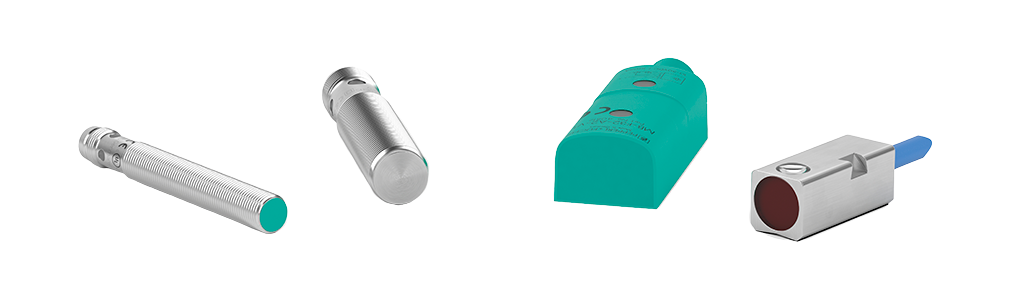

- Inductive sensors: These sensors use a magnetic field to surround themselves in order to detect metal things. Your metal object alters the magnetic field when it enters the function, activating the sensor output. Inductive magnetic sensor by Namur Pepperl Fuchs come in a range of sizes, detecting configurations, and output kinds.

- Magneto-inductive sensors: These sensors are similar to namur inductive sensor, but they are designed to detect only ferromagnetic metals such as steel, nickel or cobalt. Namur Pepperl Fuchs magneto inductive sensors offer high resistance to interference and can be used in environments with strong magnetic fields.

- Capacitive sensors: By altering the electric field surrounding its sensor, these sensors are able to detect non-metallic items including plastic, liquids, and bulk materials. There are numerous detection areas and output kinds for Namur Pepperl Fuchs capacitive sensors.

- Optical sensors: Light is used by these sensors to identify objects. There are numerous varieties of Namur Pepperl Fuchs optical sensors, such as photoelectric, laser, and light curtain sensors. They can detect small objects and have a high accuracy.

2. By type of case

- Standard sensors: These sensors have a cylindrical body with M12 or M18 threaded mounting. They are the most common type of Namur Pepperl Fuchs gauges and stones in a wide range of production.

- Compact sensors: These sensors have a smaller body, making them ideal for applications in limited space. They are available in various types and outputs.

- Embedded Sensors: These sensors are designed to be embedded in a piece of equipment or a machine. They offer a high level of protection and impact resistance.

3. At the exit

- PNP sensors: These sensors have an output that goes high when an object is detected.

- NPN sensors: These sensors have an output that goes low when an object is detected.

- Sensors with two switching points: These sensors have two outputs that switch at different detection points.

4. According to additional characteristics

- Explosion-Proof Sensors: These sensors are certified for use in hazardous areas where explosive gases or dust are present.

- Sensors with a high degree of IP protection: These sensors have a high degree of IP protection, which makes them resistant to dust, moisture and other adverse environmental factors.

- Heated Sensors: These sensors are heated to prevent freezing or condensation in cold or wet environments.

Advantages of NAMUR Sensors from Pepperl Fuchs

NAMUR sensors are fundamental in industrial automation, offering distinct benefits that position them as a preferred choice across numerous applications.

Increased Security in Dangerous Environments

In industrial settings where hazardous conditions are prevalent, safety is of utmost importance. The use of sensors that are designed to withstand and operate in dangerous environments is crucial to maintaining safety and preventing accidents.

1. Intrinsic Safety

One of the primary features that make NAMUR sensors suitable for dangerous environments is their intrinsic safety. These sensors are designed to operate with low energy, significantly reducing the risk of sparking or overheating, which could lead to explosions or fires in volatile settings. With ATEX and IECEx certifications, strict safety requirements are met by namur sensor pepperl fuchs, guaranteeing adherence to laws in risky sectors including oil and gas, chemical processing, and pharmaceuticals.

2. Resistance to Environmental Factors

NAMUR sensors are built with robust materials like stainless steel or brass, providing resistance to these environmental factors. This durability ensures that the sensors maintain their reliability and safety, even in challenging conditions, reducing the risk of equipment failure and potential accidents.

3. Stable and Consistent Operation

Sensors are designed to offer reliable signal output, minimizing the risk of false readings or malfunctions. This stability helps prevent unexpected issues that could lead to hazardous situations, ensuring a safer working environment.

4. Compatibility with Safety Systems

NAMUR sensors standardized signal output allows for seamless integration with emergency shutdown systems and other safety mechanisms. This compatibility ensures that the sensors can work in tandem with other safety measures, providing an additional layer of protection in dangerous environments.

Universal Use Cases for NAMUR Sensors

The well-known NAMUR sensors from Pepperl Fuchs for their versatility and adaptability, making them suitable for a wide range of industrial applications. Their universal use cases stem from their intrinsic safety, contactless detection, and robust design.

1. Industrial Automation

Conveyor systems, robotic arms, and automated assembly lines are perfect places for NAMUR sensors to work since they can detect product movement and direct automated processes without requiring physical contact.

2. Process Control

In industries such as chemical processing and oil and gas, these sensors help control flow, pressure, and temperature. Their intrinsic safety makes them suitable for hazardous environments, while their consistent signal output ensures accurate monitoring and control.

3. Safety Systems

They are often integrated into emergency shutdown systems, safety interlocks, and other safety-critical applications to ensure that operations can be halted or adjusted in response to safety concerns.

4. Material Handling

NAMUR sensors non-contact detection allows them to identify and track objects without causing damage or wear. This capability is particularly useful in industries like logistics, packaging, and warehousing, where efficient material handling is essential.

5. Position Detection

Sensors can be used to detect the position of robotic arms, conveyor belts, and other moving components, ensuring proper alignment and operation.

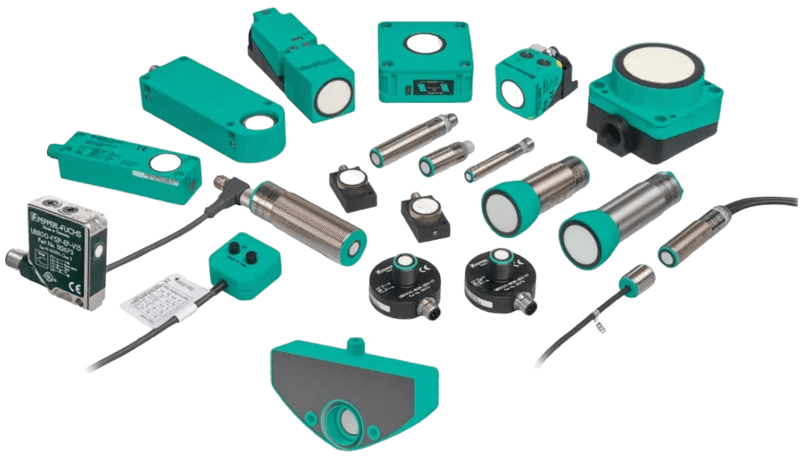

6. Level and Distance Sensing

In industries such as food processing and pharmaceuticals, they can monitor the level of liquids or powders in tanks and hoppers. Their sensitivity allows them to detect minute changes, providing accurate data for process control and quality assurance.

7. Versatile Mounting Options

NAMUR sensors can be mounted using threaded connections, flanges, or brackets, allowing them to be installed in various configurations. This adaptability makes them suitable for a wide range of industrial setups.

Compatibility with a Wide Range of Systems

P&f namur sensor designed to be compatible with a broad range of industrial control systems, making them a flexible and adaptable solution for automation and process control. This compatibility is the key advantages that set these sensors apart, allowing for seamless integration into existing systems and reducing the need for extensive reconfigurations.

1. Standardized Signal Output

One of the reasons NAMUR sensors can integrate with various control systems is their standardized signal output. This standardization simplifies the process of connecting sensors to existing systems, allowing for easy integration without the need for complex wiring or custom configurations.

2. Support for PNP and NPN Outputs

NAMUR sensors from Pepperl Fuchs offer both PNP and NPN output types, which are common configurations in industrial control systems. The ability to choose between PNP and NPN outputs allows users to select the most appropriate sensor for their specific application and system requirements.

3. Compatibility with Safety Systems

ATEX and IECEx certified, these sensors are intrinsically safe and suitable for use in hazardous settings. They can be used with safety interlocks, emergency shutdown systems, and other safety-critical applications.

4. Smooth Assimilation into Current Infrastructure

This feature is particularly valuable for industries that need to upgrade or expand their system automation without significant downtime. By offering compatibility with a wide range of systems, NAMUR sensors can be added to current setups with minimal disruption, reducing installation costs and time.

Pepperl Fuchs's NAMUR Sensors in the Future

With sectors continuing to embrace automation, digitization, and higher safety regulations, Pepperl Fuchs' NAMUR sensors appear to have a bright future. As technology evolves, these sensors are expected to play an even more significant role in industrial applications. Here are some trends and developments that could shape the future of NAMUR sensors from Pepperl Fuchs.

- Integration with IoT and Industry 4.0

As Industry 4.0 gains momentum, NAMUR sensors are set to become key components in the Industrial Internet of Things (IIoT). Pepperl Fuchs is likely to focus on IoT-enabled NAMUR sensors to meet the growing demand for connected automation solutions.

- Enhanced Safety and Compliance

Safety will remain a top priority, especially in hazardous environments. Future NAMUR sensors from Pepperl Fuchs will likely feature enhanced intrinsic safety measures and improved compliance with safety standards.

- Increased Sensitivity and Precision

Future NAMUR sensors may offer increased sensitivity and precision, allowing for more accurate detection and measurement. This improvement can lead to better process control and automation, resulting in higher productivity and reduced waste.

- Miniaturization and Flexibility

Smaller sensors with enhanced functionality can be integrated into tighter spaces and more complex systems. Pepperl Fuchs might focus on creating smaller NAMUR sensors without compromising safety or performance, providing greater flexibility in industrial design and automation.

- Sustainable and Environmentally Friendly Designs

Sustainability is becoming increasingly important in industrial automation.The use of recyclable materials and energy-efficient technology could become a key selling point for NAMUR sensors.

Conclusion

NAMUR sensors from Pepperl Fuchs are essential in industrial automation, blending safety, reliability, and versatility. Their intrinsic safety design allows them to operate in hazardous environments, while contactless detection extends their lifespan and minimizes maintenance. Built to withstand harsh conditions, these sensors are durable and consistently reliable. Their ease of integration into pre-existing infrastructures arises from their compatibility with a wide range of control systems, which improves flexibility. P&f namur sensor a recommended choice for companies that prioritize efficiency and safety in their automated operations because of these combined benefits.