Pepperl Fuchs Error Codes: Understanding Error in Industrial Machinery

01.02.2024

CONTENTS:

- Understanding Pepperl Fuchs Error Codes

- Types of Pepperl Fuchs Error Codes: A Comprehensive Exploration

- Troubleshooting Pepperl Fuchs Error Codes: A Practical Approach

- Preventive Measures for Smooth Operations: Nurturing a Glitch-Free Environment

- Summarizing the significance of understanding and resolving Pepperl Fuchs error codes

Step into a transformative expedition where Pepperl Fuchs error codes metamorphose from cryptic symbols into actionable insights. Within the realm of industrial machinery, these codes are the linchpin for ensuring a seamless and efficient operation. If the blinking lights and coded messages on your equipment have ever left you perplexed, rest assured – you're not navigating this challenge alone.

Our mission is to delve deep into the profound importance of comprehending pepperl fuchs Error Messages. Beyond mere decryption of technical nuances, our aim is to empower you with the skills to troubleshoot and resolve issues with confidence.

We don't just aim to help you understand but to master the language of Pepperl Fuchs error codes. The outcome? A more harmonious and trouble-free industrial experience that places you in command of your machinery's intricate conversations.

Understanding Pepperl Fuchs Error Codes

Pepperl Fuchs error codes, cryptic in their manifestation, often trace their roots to a variety of sources. Chief among these are sensor malfunctions, where physical damage, misalignments, or general wear and tear of components can compromise their functionality. Communication errors frequently arise due to disruptions in data transmission between devices, leading to the misinterpretation of crucial signals. Power supply issues, including voltage fluctuations and inadequate power delivery, can introduce instability into the system. A comprehensive understanding of these common causes is crucial for technicians and operators, providing a roadmap for accurate diagnosis and effective resolution.

Common Pepperl Fuchs Error Codes and Causes:

| Error Code | Description |

|---|---|

| SFERR001 | Sensor Data Misinterpretation |

| SFERR002 | Sensor Malfunction |

| SFERR003 | Discrepancies in Sensor Readings |

| CEERR001 | Communication Interference and Signal Loss |

| CEERR002 | Network Congestion |

| CEERR003 | Device Incompatibility |

| PSERR001 | Voltage Fluctuations |

| PSERR002 | Power Interruptions |

| PSERR003 | Power Surges |

How Error Codes Impact Industrial Processes

The introduction of Pepperl Fuchs error codes into industrial processes initiates a cascade of effects, intricately interwoven with the seamless operation of machinery. These codes disrupt the delicate ballet of automation, leading to suboptimal performance or even complete shutdowns. The repercussions include production delays, decreased efficiency, and heightened operational costs. Understanding the profound impact of these error codes on industrial processes is not just about addressing immediate issues but also strategizing for prevention. This comprehension not only facilitates immediate solutions but also informs strategies for preventing future occurrences, ensuring a more resilient and reliable industrial ecosystem.

The Significance of Prompt Error Resolution

The temporal aspect of resolving Pepperl Fuchs error codes holds significant weight in the dynamic industrial landscape. Swift resolution is pivotal in minimizing downtime, allowing for the unimpeded continuation of production processes. Beyond operational considerations, prompt error resolution plays a crucial role in maintaining workplace safety. By preemptively tackling potential hazards linked to malfunctioning equipment, this proactive approach not only prevents financial losses but also upholds the efficiency and safety standards crucial for thriving industrial environments. Recognizing the critical importance of resolving errors promptly underscores the need for vigilance, swift action, and a proactive stance toward maintenance and troubleshooting

Types of Pepperl Fuchs Error Codes: A Comprehensive Exploration

Understanding Pepperl Fuchs error codes is vital for maintaining the smooth operation of industrial processes. These codes act as digital fingerprints, revealing insights into the health and performance of various components. In this section, we'll explore the intricacies of sensor-related error codes, communication errors, and power supply issues, accompanied by a general table summarizing key error codes for each category.

General Table of Pepperl Fuchs Error Codes:

| Error Code | Description |

|---|---|

| SFERR001 | Sensor Data Misinterpretation |

| SFERR002 | Sensor Malfunction |

| SFERR003 | Discrepancies in Sensor Readings |

| CEERR001 | Communication Interference and Signal Loss |

| CEERR002 | Network Congestion |

| CEERR003 | Device Incompatibility |

| PSERR001 | Voltage Fluctuations |

| PSERR002 | Power Interruptions |

| PSERR003 | Power Surges |

Now, let's delve into the details of each category:

Sensor-related Error Codes

- Sensor Data Misinterpretation:

Sensors, being the frontline data gatherers, might occasionally misinterpret data due to environmental changes, wear and tear, or calibration issues. Addressing these misinterpretations involves recalibrating sensors, ensuring they accurately capture and convey data.

- Sensor Malfunction:

Malfunctions in sensors can stem from internal failures, connectivity issues, or environmental stress. Troubleshooting sensor malfunctions involves inspecting internal components, ensuring proper connections, and creating an environment conducive to sensor longevity.

- Discrepancies in Sensor Readings:

Conflicting or inconsistent sensor readings may arise from calibration misalignment or sensor drift. Resolving these discrepancies entails recalibrating sensors and implementing measures to prevent drift, ensuring consistent and reliable data readings.

Communication Errors

1. Interference and Signal Loss:

External interference or signal loss can disrupt communication between devices. Mitigating interference involves identifying sources of disruption and implementing shielding mechanisms or signal amplification to ensure a stable and continuous data flow.

2. Network Congestion:

Congestion within the network can impede data exchange. Optimizing network traffic, identifying bottlenecks, and improving data transmission efficiency can alleviate network congestion, minimizing communication errors.

3. Device Incompatibility:

Compatibility issues among devices within the system can hinder effective communication. Addressing device incompatibility involves ensuring devices speak a common language, possibly through firmware updates or choosing compatible components during system design.

Power Supply Issues

- Voltage Fluctuations:

Variations in voltage can destabilize the entire system. Regulating voltage involves implementing voltage stabilizers or regulators, ensuring a consistent and reliable power supply to prevent disruptions.

- Power Interruptions:

Sudden interruptions in power supply can lead to error codes. Preventive measures, such as backup power systems like uninterruptible power supplies (UPS), help maintain continuous power, mitigating the impact of sudden outages.

- Power Surges:

Power surges pose risks to the integrity of the system. Protecting against surges involves employing surge protectors or suppressors, acting as barriers to prevent excessive voltage from damaging sensitive components.

By understanding the nuances of sensor-related issues, communication errors, and power supply challenges, operators can decipher Pepperl Fuchs error codes effectively. The provided table serves as a quick reference guide for identifying and addressing specific error codes within each category, ensuring a well-maintained and smoothly functioning industrial system.

Troubleshooting Pepperl Fuchs Error Codes: A Practical Approach

When it comes to the intricate realm of Pepperl Fuchs error codes, having a robust troubleshooting strategy is essential for minimizing downtime and maintaining operational efficiency. This section provides a detailed guide to troubleshoot Pepperl Fuchs error codes, offering insights into a step-by-step identification process, utilizing user manuals and documentation effectively, and making the most of contacting Pepperl Fuchs support in a language that resonates with human operators.

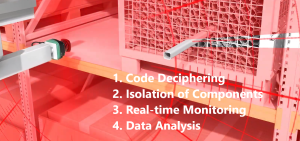

Step-by-step Guide to Identifying Errors

Navigating the labyrinth of error codes starts with a systematic identification process:

Code Deciphering:

Begin by decoding the error code itself. Think of it as translating a message; the code often reveals the specific hiccup within the system.

Isolation of Components:

Isolate the affected components for closer inspection. This step is akin to a health checkup, focusing on sensors, communication devices, and power supplies individually.

Real-time Monitoring:

Utilize real-time monitoring tools as your detective's magnifying glass. Track the system's behavior to catch the error in action, making identification more precise.

Data Analysis:

Dive into historical data for patterns. This is like looking at the system's past to identify recurring issues or specific conditions triggering the error.

Utilizing User Manuals and Documentation

User manuals and documentation act as trusty companions during troubleshooting:

Code Lookup:

Open the manual for a detailed code lookup. Much like consulting a dictionary, the manual provides meanings and potential causes for specific error codes.

Component Information:

Explore the documentation for component specifications. This is your reference guide to understanding sensors, communication protocols, and power supply requirements.

Troubleshooting Guides:

Check for troubleshooting guides tailored to specific error scenarios. Think of these guides as roadmaps, offering clear instructions to navigate and resolve issues efficiently.

Firmware and Software Updates:

Look for updates in the manual. Updating firmware and software is similar to keeping your system's software in tune with the latest solutions, addressing known issues.

When Contacting Pepperl Fuchs Support

When all else fails, and the complexity of the issue requires expert assistance, it's time to connect with Pepperl Fuchs support:

Gather Information:

Before reaching, gather pertinent information, including error codes and any steps you've taken. This helps streamline the support process and speeds up the resolution.

Online Support Portal:

Explore Pepperl Fuchs' online support portal for self-help options. It's like checking an FAQ section before seeking direct assistance, often providing quick solutions.

Technical Support Contact:

When direct support is needed, contact Pepperl Fuchs' technical support. Share your concerns in a straightforward manner, detailing the issue and the steps you've already taken.

Remote Assistance:

Embrace the option of remote assistance if offered. It's like having a technician right beside you, remotely accessing the system to identify and address the issue firsthand.

Preventive Measures for Smooth Operations: Nurturing a Glitch-Free Environment

In the intricate of industrial processes, preventing problems is often more efficient than addressing them. We look practical preventive measures for minimizing pepperl fuchs fault codes, focusing on straightforward approaches that resonate with human operators.

Regular Maintenance to Avoid Errors

Think of regular maintenance as giving your industrial setup a periodic check-up. Just as you'd ensure your car runs smoothly with routine tune-ups, regular maintenance involves inspecting sensors, calibrating components, and performing system checks. By addressing potential issues before they escalate, you create a robust defense against unexpected errors, ensuring the continuous harmony of your industrial processes.

Upgrading Firmware and Software

Technology advances at a rapid pace, and your industrial system should keep up. Upgrading firmware and software is like giving your system a technological boost. Similar to updating your phone to access new features, Pepperl Fuchs releases updates to improve performance and address potential bugs. By staying current with these upgrades, you equip your system to handle evolving challenges, reducing the chances of encountering outdated software-related errors.

Employee Training on Error Prevention

In the grand symphony of industrial operations, employees play a crucial role as conductors of error prevention. Imagine training drivers not just to react to road signs but to anticipate potential challenges. Employee training on error prevention focuses on recognizing early signs of malfunctions, understanding error codes, and implementing basic pepperl fuchs troubleshooting steps. By educating and empowering your team, you create a human layer of defense, fostering a culture where every operator contributes to a glitch-free environment.

Summarizing the significance of understanding and resolving Pepperl Fuchs error codes

Grasping and tackling Pepperl Fuchs error codes is like deciphering the secret language of your industrial machinery. These codes, initially puzzling, are actually your system's way of talking to you. Understanding them means gaining the upper hand in maintaining the smooth flow of operations. We've explored the reasons behind errors, learned about different types, and discovered effective troubleshooting techniques.

Understanding and addressing Pepperl Fuchs error codes is not just a technical puzzle; it holds significant practical value. It's a proactive strategy aimed at preventing disruptions, saving valuable time, and, ultimately, safeguarding financial resources. Mastering the language of these error codes serves as a key to unlocking a smoother and more efficient industrial journey. It's a skill worth acquiring, and it's high time we all become fluent in it to navigate the complexities of industrial processes with confidence and efficiency.