Pneumatic solenoid valve types

24.01.2024

Pneumatically actuated solenoid valve is generally used wherever a solenoid actuator cannot be used or the process medium is abrasive, corrosive, or very viscous, which precludes the use of a solenoid-operated shut-off valve. Pneumatically actuated valves are widely used in the food industry (sterilizers, thermal chambers), water treatment and water purification, medical (sterilizers, autoclaves), and pulp and paper industry and power industry.

Choosing a Pneumatic Solenoid Valve for Your Application

The solenoid valve is designed to control the flow of liquid and gaseous products at a distance. It can be either a shut-off valve or a control valve. It can be controlled either manually or by means of automation systems. In its design and purpose, the electromagnetic valve is very similar to a conventional one, with the difference that the shut-off element is not set in motion by muscular force, but by a solenoid, an electromagnet with a movable core. When voltage is applied to the solenoid inductance coil, it, depending on the polarity, retracts or expels the core connected to the valve stem.

These shut-off and control devices are used in complex industrial installations as well as in-home heating systems, water supply, and household appliances. They are also used in liquid fuel vehicles. To reduce costs, some businesses purchase solenoid valves based on price alone. However, it is a mistake to assume that all valves are the same and little can go wrong with these seemingly simple devices, which typically consist of a coil, plunger, and seat. A highly engineered compressed air solenoid valve may cost more, but the lifetime costs will be much lower than cheaper equivalent valves.

It is important to pay attention to product quality and safety. One of the best manufacturers on the market is the Italian brand ODE, whose compact and reliable devices are designed for high loads and long hours of operation. The diaphragm in each manufacturer's product is highly durable and the body is flawlessly sealed. Given the complexity of the selection of solenoid valves - when choosing you need to pay attention to dozens of factors, we recommend that in this matter, contact only experts.

What to look for when choosing a valve:

- Working pressure range. The operating pressure is the pressure at which the valve will function properly and operate safely. The permissible pressure range for the valve is usually specified at 200C. Note that valves designed for relatively high pressures tend to perform poorly or not at all at pressures close to zero.

- Diameter of connection (DN). Measured in inches (1/2, 3⁄4, 3/8, etc.) or millimeters (25 mm, 50 mm, etc.). Keep in mind that often the valve's full bore is smaller than its nominal bore.

- Body material of solenoid valves. The basic materials are brass, stainless steel, cast iron, different types of plastics.

- Media of application. Typical media for solenoid valves: air, inert gases, fuel gas, water, oil, or steam. Both the diaphragm (in diaphragm valves) or seal (in piston valves) and the body material must be considered for the application.

The material of the solenoid valve must be compatible with the medium. Otherwise, corrosion of the body or deterioration of the diaphragm or seal material may occur. The maximum and minimum temperature of the medium is also important. High-temperature media, such as superheated steam, can heat the solenoid coil which will adversely affect its operation. Whatever the operating medium, no dirt or foreign bodies should enter the valve cavity.

Types of pneumatic solenoid valves

When controlling the flow of liquids and gases in modern industrial plants are most often used two types of valves: solenoid valves and valves with pneumatic actuators. The sheer number of different valve models of both types, designed for a wide variety of applications, has meant that the choice between the air solenoid valve and the pneumatically actuated valve is no longer obvious.

Solenoid valves are distinguished by their operating position:

- normally closed - as long as no voltage is applied to the coil, the valve is closed;

- normally open - the principle is the opposite, i.e. the valve is open as long as there is no voltage to the actuator;

- bistable - they switch from open to the closed position under the influence of the impulse. In contrast to the other types, bistable valves do not require DC voltage to hold the valve closed or open, but they operate from DC sources.

According to the principle of operation, electromagnetic valves are distinguished:

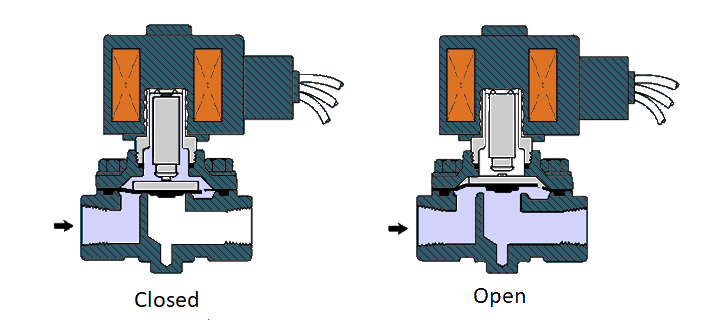

- direct action (no diaphragm) - the plunger, which is the core of the solenoid, directly opens and closes the orifice through which the working medium moves from the inlet to the outlet port;

- indirect action - the plunger closes or opens the discharge port, changing the pressure in the supramembrane cavity and causing the diaphragm to close or open the main port for fluid movement;

- combi - plunger connected to rigid center diaphragm; when actuated, the solenoid core forcibly pulls the diaphragm up to open the balancing orifice, thus relieving the pressure in the diaphragm chamber, raising the diaphragm, and opening the main orifice.

Pneumatic Solenoid Valves Advantage

The pneumatic solenoid valve can normally operate under vacuum, negative pressure, and zero pressure, but its diameter usually does not exceed 25 mm. It can also operate at zero differential pressure or vacuum or high pressure, but the capacity is high and requires horizontal installation. The upper limit of the fluid pressure range is high and can be set arbitrarily (optional), but must meet fluid differential pressure conditions.

Solenoid models are more reliable because they have no mechanical parts to wear. This device can be installed in systems with a wide variety of pressure ratings, as this characteristic does not affect its operation. It is because of these characteristics that solenoid models dominate among shut-off valves on the market.

Pneumatic Solenoid Valve has the following features:

- The reliability of solenoid valves becomes even more important in extreme operating conditions. For example, consider valve actuator control at very low temperatures.

- There is ample documented evidence that solenoid valve reliability levels decrease as temperatures drop. The solution to this problem is certified solenoid valves that operate at temperatures of -60...+90 C.

- When operating in corrosive environments, such as those containing sulfuric gas, where stress sulfide cracking often occurs, all materials of the valve's internal and external components must meet NACE requirements.

- In general, for any extreme operating environment, it is recommended to select solenoid valves that are corrosion-resistant and long-lasting and are certified by industry-recognized bodies such as Exide and TÜV.

- Finally, for potentially explosive environments, engineers should opt for solenoid valves with a wide range of explosion protection options and certifications that make them suitable for use in hazardous environments - TR TS 012/2011, ATEX, IECEx, NEMA/UL/CSA, NEPSI, PESO, INMETRO, and KOSHA.

The range of electromagnetic devices is quite large. They have various distinctive features in the design. But usually, this does not greatly affect the operating parameters. The most popular is the one-inch electromagnetic devices, which have a flow rate of up to 40 l/min.