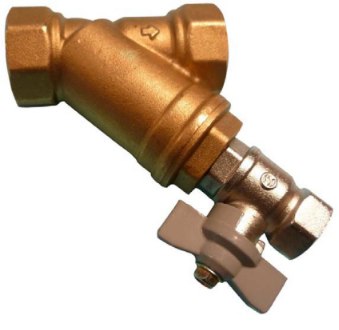

Female BSP brass strainer with drain valve - PN16 - ACS

f3230

“Y“ type cast iron strainer – ASA150

f4200

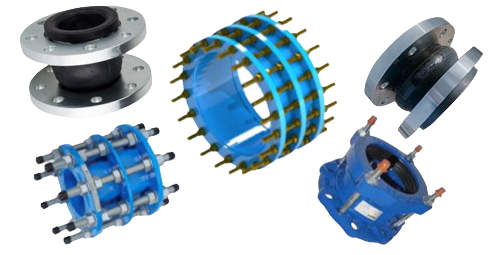

Flanged ductile iron H-strainer PN10

f4240

Flanged ductile iron H-strainer PN16

f4246

Strainer basket type ductile iron - PN16

f4250

Ductile iron strainer - PN25

f4256

Strainer basket type ductile iron - PN25

f4260

Ductile iron strainer - PN40

f4266

Strainer basket type ductile iron - PN40

f5206

Strainer basket type carbon steel - PN10

f5246

Strainer basket type carbon steel - PN16

f5256

Strainer basket type carbon steel - PN25

f6240

Flanged type “Y“ Stainless steel strainer PN16

FADK 14I4470/S14/IO art. 11014496

| measuring distance Sd | 50 ... 400 mm |

| adjustment | IO-Link |

| Teach-in range min. | > 20 mm |

| operating temperature | 0 ... +50 °C |

Weld-in nozzle with PTFE plug and counter flange with venting element

| Type | I/O and Feedback Options / MotiFlex |

- 1-channel

- Fully compatible replacement for FB3203B

- Input Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2- or 3-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- HART communication also for separately powered devices

- Simulation mode for service operations (forcing)

- Line fault detection (LFD) and Live Zero monitoring

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD)

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Module can be exchanged under voltage (hot swap)

- Installation in suitable enclosures in Zone 1

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Output with bus-independent safety shutdown

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via PROFIBUS DP

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS TCP

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- HART communication via MODBUS TCP

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Standard enclosure for FB-System

- Max. 5 slots for I/O modules

- For FOUNDATION Fieldbus H1

- Impact resistance enclosure, IP66/NEMA 4X

- Packaged certified solution

- Installation in Zone 1

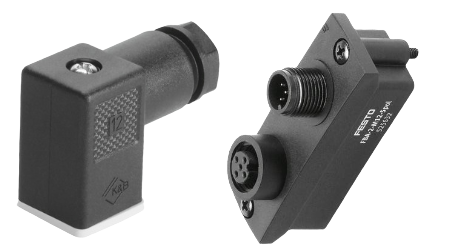

Festo FBA-2

- 8 segments, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 4 segments, redundant, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 8 segments, redundant, individual modules per segment

- Customized for Invensys, FBM228

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Dual, redundant bulk power connections