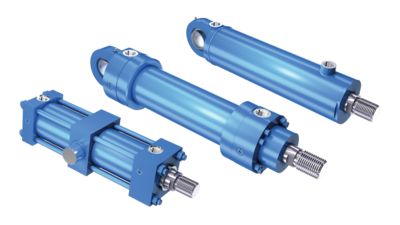

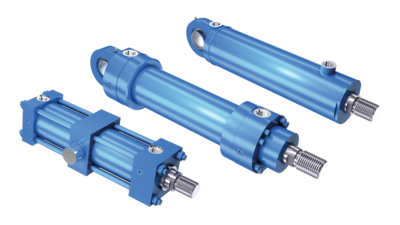

Bosch Rexroth Cylinders

The Seal Kit CD250.200 125MA from Bosch Rexroth is a seal kit designed for hydraulic cylinders of the CD250 series with a piston diameter of 200 mm and a piston stroke of 125 mm. This seal kit is made of high quality materials, which ensures its resistance to wear, high pressure and chemical resistance.

The Seal Kit CDH.160 110M from Bosch Rexroth is a seal kit designed for use in the CDH series of hydraulic cylinders. This seal kit is made of high quality materials and is designed to provide reliable and long-lasting performance in the harshest conditions.

cdh2 rexroth

- Maximum speed: 0.3 m/s (0.98 ft/s)

- Working volume: up to 126.7 L (33.5 gal)

- Stem volume: up to 18.9 L (5 gal)

- Operating temperature: -20°C to +80°C (-4°F to +176°F)

cdm1 rexroth

- Type: Double acting hydraulic cylinder

- Maximum piston speed: up to 1 m/s

The Seal Kit CY210.063 045MXZY7667 from Bosch Rexroth is a set of seals designed for use in hydraulic systems. It is used to prevent fluid leakage from cylinders, motors and other components. The set consists of different types of seals made of different materials such as rubber, fluorine rubber, and polyurethane.

cdt3me5

- Storage temperature: from -40°C to +100°C

- Hydraulic oil ISO VG 32 - 46

- Accuracy class: ISO H2

cdt3mp5

- Type: Double acting hydraulic cylinder

- Manufacturer: Bosch Rexroth

- Series: CDT3MP5

- Test pressure: 240 bar (24 MPa)

- Working fluid temperature: From -20°C to +80°C

cdh1 rexroth

- Type: Double action

- Body: Aluminum

- Stem: Steel with hard chrome coating

r900999t31 Rexroth Hydraulic Cylinder

- Elevation speed: 0.1 m/s

- Volume of the working chamber: 0.22 l

- Stem volume: 0.04 l

- Operating temperature: from -20°C to +80°C

- Fluid type: Hydraulic oil ISO VG 32

- Viscosity: from 20 to 100 cSt (at 40°C)

rexroth 7294

- Working fluid temperature: From -20°C to +100°C (-4°F to +212°F)

- Viscosity of working fluid: Up to 32 cSt (centistokes)

- Maximum air pressure: 10 bar (145 psi)

SEAL KIT CY210P063/028MXZ18292

Bosch Rexroth are known for having many years of experience in the development and production of hydraulic cylinders, making their products some of the best on the market. Their cylinders play a key role in the operation of hydraulic systems, providing precise and powerful movement in a variety of industries. As one of the world leaders in hydraulic equipment, Bosch Rexroth offers you high-quality cylinders that meet the most stringent requirements for performance and reliability.

The main advantages of Bosch Rexroth cylinders include:

- High quality and reliability. Each cylinder undergoes strict quality control to ensure durability and trouble-free operation.

- Innovative technologies. Constant research and development allow us to offer innovative solutions that meet the highest standards.

- A wide range. Bosch Rexroth offers cylinders in a variety of sizes and configurations to meet the needs of a wide range of industries.

Eltra Trade is the official distributor of Bosch equipment, offering a wide range of cylinders and professional support, guaranteeing you high-quality and reliable products.

Why Choose Bosch Rexroth Cylinders?

Bosch Rexroth cylinders are one of the most reliable and efficient solutions for hydraulic systems in various industries. Let's look at them in more detail.

Accuracy

High positioning accuracy: Bosch Rexroth cylinders provide precise and stable movement, which is critical for processes requiring high precision.

Durability

Using high-strength alloys and advanced processing technologies increases the cylinders' service life.

High performance

The cylinders provide a fast and accurate response to control signals, which improves overall system performance.

Energy efficiency

Innovative sealing systems and optimized designs reduce leakage and energy loss. Modern technologies allow for minimizing energy consumption while maintaining high performance.

Application in various industries

- Process automation. Used in robotics, machine tools, and other automated systems to accurately and efficiently perform production operations.

- Injection molding and stamping. Used to create high pressures and precise motion control when processing materials.

- Conveyor systems. Cylinders ensure the precise and reliable movement of goods and materials through production lines.

- Manipulators and robots. Used to control the movement and positioning of working tools.

- Construction equipment. Cylinders are used in excavators, loaders, and cranes to provide powerful and smooth movement.

- Agricultural machinery. Ensure reliable operation of tractors, combines, and other machines.

Types of cylinders

- Bosch Rexroth hydraulic cylinders. A basic type of cylinder that uses hydraulic fluid to generate force and movement. Hydraulic cylinders are widely used in industry, construction, and mobile hydraulics.

- Bosch Rexroth pneumatic cylinders. Use compressed air to create movement. Pneumatic cylinders are suitable for light to medium loads and are often used in automation and production lines.

- Steering cylinders. Specialized cylinders for steering systems. They are used in cars, ships, and other equipment that require precise motion control.

Technological advantages

- Innovative sealing systems. Seals are designed to minimize leakage and improve durability.

- Built-in sensors. The cylinders can be equipped with sensors to monitor position, pressure, and other parameters in real time.

Explore Our Bosch Rexroth Cylinder Range

Eltra Trade offers a wide range of Bosch Rexroth cylinders classified by type, size, and operating pressure. Let's look at each category in more detail.

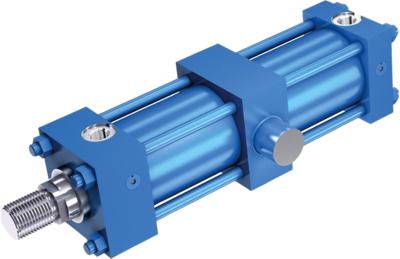

Welded cylinders

The welded cylinder has a compact design in which the body and back cover are joined by welding. This ensures high strength and leak resistance. They are often used in excavators, bulldozers, and other machines that require high loads.

Telescopic cylinders

The telescopic cylinder consists of several extendable sections, which allow for a large stroke with relatively compact dimensions when folded. They are used for lifting bodies and containers.

Linear actuators

The linear actuator converts a motor's rotary motion into a rod's linear motion. They can be electric, hydraulic, or pneumatic and are used for precise positioning in robots and automated systems.

Classification by size and working pressure

Cylinders are classified by piston diameter and stroke. The selection of sizes depends on the required force and stroke for a particular application.

The operating pressure of the cylinders also varies depending on their design and purpose:

- Low pressures of up to 100 bar are used in light industrial and domestic applications.

- Medium pressure up to 250 bar is suitable for most industrial applications.

- High pressures up to 700 bar and above are used in heavy equipment and highly loaded systems.

Cylinder Accessories & Spare Parts

Bosch Rexroth offers a wide range of hydraulic system components and spare parts for its cylinders, including fasteners, sensors, seals, and others.

Fastenings

Bosch Rexroth cylinder mounts include a variety of mounting components, such as:

- Flanges. For rigid fixation of the cylinder in a certain position.

- Hinged and corner mountings. Allow the cylinder to move and rotate in different directions.

- Brackets and brackets. For secure and flexible mounting of cylinders on various Bosch Rexroth surfaces.

Sensors

Bosch Rexroth offers sensors for monitoring the position and condition of cylinders:

- Position sensors. For precise tracking of cylinder rod position.

- Pressure sensors. To control the pressure inside the cylinder, which helps prevent overloading.

Seals

Seals are key components to prevent leaks and maintain cylinder pressure:

- O-rings. For sealing rod and piston.

- Cuffs and pads. To protect against contamination and maintain the tightness of the Bosch Rexroth system.

Other components

Bosch Rexroth also offers:

- Hoses and fittings. For reliable connection to hydraulic systems.

- Filters. To clean hydraulic fluid and protect components from contamination.

- Hydraulic cylinders repair tools. A set of special tools that will allow you to easily carry out the necessary manipulations with the equipment.

The use of original Bosch Rexroth spare parts is critical to reliability because original parts undergo strict quality control and meet all manufacturer specifications. The manufacturer also guarantees full compatibility with your cylinders, which reduces the risk of incorrect operation. The use of original spare parts extends the life of the equipment and reduces the cost of maintenance and repair of Bosch Rexroth.

Eltra Trade experts recommend that you follow several rules that will allow you to preserve your equipment for as long as possible:

- Regular maintenance. Preventative maintenance to keep equipment in working order.

- Repair and replacement. Fast and high-quality replacement of worn or damaged parts with original components.

- Modernization. Updating existing equipment to improve its performance and meet modern standards.

Eltra Trade is your trusted rexroth air cylinder distributors. We offer a comprehensive range of Bosch Rexroth pneumatic components to meet your industrial automation needs. Whether you require product information, technical assistance, or customized solutions, we are here to help.