Pepperl+Fuchs Industrial Communication and Vision

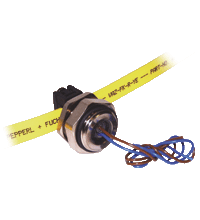

- One piece housing

- Simple and fast mounting

- Gold-plated and machined contacts

- Oil and abrasion resistant PUR line appropriate for drag chains

- Immunity to vibration

- Degree of protection IP68 / IP69K

- Halogen-free

- Metal housing

- AS-Interface cable can be mounted in any position

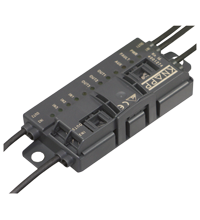

- Cable extension to up to 300 m per segment possible

- Simple commissioning by means of rotary selector

- Optimized bus terminator parameters

- Free from substances that impair paint wetting

- A/B slave with extended addressing possibility for up to 62 slaves

- Inputs for 3-wire sensors

- Power supply of the inputs and outputs from the external auxiliary voltage

- Communication monitoring

- Function display for bus, external auxiliary voltage, in- and outputs

- Cable piercing method with gold plated contact pins

- M12 connection, e.g., suitable for Lenze Smart Motor drives and SEW MOVI-SWITCH

- Integrated communication monitoring function

- Outputs short-circuit and overload proof

- Supply of the inputs and the outputs from AS-Interface

- Function display for bus, inputs and outputs

- Connection via lead

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Resolution 1280 x 960 pixel

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Web interface for easy access to video files and live streams

- Video ring buffer with a pre-run buffer for automatic recording of video up to 60 seconds before and after a situation that requires fault analysis or documentation

- Trigger video/image capture via UDP, REST API, or a digital hardware input for easy integration

- Find situations of interest quickly due to timestamped events

- REST API for full HMI integration of all camera functions

- Wide range of detection tools for flexible inspection tasks

- Combinable vision tools for feature detection, completeness checking, code reading, text recognition and object position checking

- 32 Jobs on-board can be saved

- Integrated illumination

- Mechanical focus adjustment

- Easy integration with flexible programmable data output