Pepperl+Fuchs Purge and Pressurization Systems

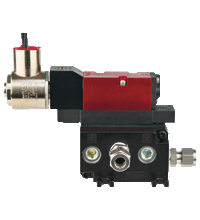

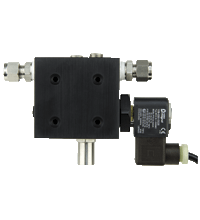

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

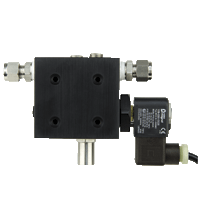

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

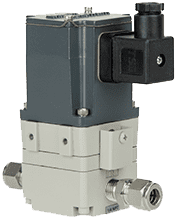

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

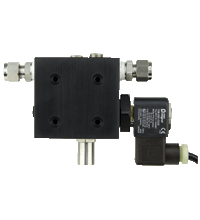

- Intrinsically Safe, 4 ... 20 mA proportional valve

- Pneumatic connections 10 mm compression ferrule tube fittings

- ATEX certification

- Maximum flow of around 8 scfm

- Closed loop flow rate control for precise dilution applications

- Must be used in conjunction with an EPV-7500-* vent

- Low cost, compact design, easy to use

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Must be used in conjunction with an EPV-7500-* vent

- External mount, square box

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Manual valve, no electrical power requirement

- Purge and pressurization valving in one device

- 316 SS

- External Mount

- 20-30VDC

- M2

Purge &Pressurization

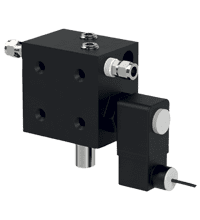

- Suitable for Zone 1 21 operation, ATEX/IECE certification

- Manifold combines the digital valve for purging and the needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- NFPA 70, NFPA 496, ISA 12.4 standards

- Optional alarm output indicates air lock failure

- Type Y system certified for Class I and Class II, Division 1 to Division 2

- Type Z system certified for Class I and Class II, Division 2 to nonhazardous area

- Class I enclosure volume up to 2 ft3

- Class II enclosure volume up to 10 ft3

- NFPA 70, NFPA 496, ISA 12.4 standards

- Optional alarm output indicates air lock failure

- Type Z system certified for Class I, Division 2 to nonhazardous

- Enclosure volume up to 15 ft3

- 100% automatic purge and pressurization system including purging, temperature and leakage control, alarming and system power

- Third party approvals for Class I, II, Div. 2 and Zone 2/22

- Universal mounting

- RTD inputs for temperature alarm and control

- Five standard purge programs

- Suitable for Zone 2 22

- ATEX IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

What Are Purge and Pressurization Systems?

Purge and pressurization systems are intrinsic safety barriers implemented in hazardous environments to prevent the entry of flammable gases or dust into electrical enclosures or equipment. These systems are commonly used in industrial settings where explosive atmospheres may be present, such as in oil and gas facilities, chemical plants, refineries, and other locations with potentially volatile substances. Below we will look at Pepperl+Fuchs hazardous area equipment in detail.

The Role of Pepperl+Fuchs in Purge and Pressurization Technology

Pepperl+Fuchs is a globally recognized provider of industrial automation and process control solutions, and the company plays a significant role in the field of purge and pressurization technology. Pepperl+Fuchs is known for its commitment to innovation. They invest in research and development to create cutting-edge purge and pressurization systems. This involves the design of integrated solutions, incorporating components such as control units, solenoid valves, pressure sensors, and other elements necessary for effective hazardous area protection.

Pepperl+Fuchs products are designed and manufactured in compliance with international standards and regulations governing hazardous area installations. This includes certifications such as ATEX (European Union), IECEx (International), and other regional certifications, ensuring that their solutions meet global safety requirements. They understand that different industries and applications have unique requirements. The company provides a range of purge and pressurization systems with modular and scalable designs. This allows users to customize solutions based on the size of enclosures, the type of hazardous substances present, and other specific needs.

P+F places a strong emphasis on user-friendly interfaces and controls. Their systems are designed to be intuitive, simplifying the configuration, monitoring, and maintenance processes. This approach enhances the usability of the technology for operators and maintenance personnel. The company integrates advanced diagnostic features and real-time monitoring capabilities into its purge and pressurization systems. This allows users to proactively identify issues, conduct preventive maintenance, and ensure the ongoing reliability of the protection system.

With a global presence and a network of experts, Pepperl+Fuchs provides comprehensive support for their purge and pressurization technology. This includes technical assistance, training, and collaboration with end-users and system integrators to address specific industry challenges. Pepperl+Fuchs recognizes the diverse applications and industries that require purge and pressurization technology. The company collaborates with customers to provide application-specific solutions, taking into account the unique requirements of each industry sector.

Types of Pepperl Fuchs Purge and Pressurization Systems

Pepperl+Fuchs specializes in creating equipment for hazardous areas. Today the company has presented an extensive line of electrical enclosure purging solutions. Let's take a closer look at them.

Type X Purge System

The Pepperl+Fuchs Bebco EPS Type X purge system effectively lowers the hazardous classification within protected enclosures from Division 1 to non-hazardous. This allows the operation of general-purpose equipment within the secured enclosure.

Type Y Purge System

The Pepperl+Fuchs Bebco EPS Type Y purging system reduces the hazardous classification within protected enclosures from Division 1 to Division 2. All equipment used inside the enclosure must carry a Division 2 rating.

Type Z Purge System

The Pepperl+Fuchs Bebco EPS Type Z purge system minimizes the hazardous classification within protected enclosures from Division 2 to non-hazardous. General-purpose equipment can be safely operated within the protected enclosure.

Ex pxb Purge System

The Pepperl+Fuchs Bebco EPS Ex pxb purge system decreases the hazardous classification within protected enclosures from Zone 1/ Zone 21 to non-hazardous. This allows the operation of general-purpose equipment within the secure enclosure.

Ex pyb Purge System

The Bebco EPS Ex pyb purge and pressurization systems provide reliable protection for operating general-purpose electrical equipment in Zone 1/21 explosion hazardous locations.

Ex pzc Purge System

Ex pzc purge systems reduce the hazardous classification within protected enclosures from Zone 2 to non-hazardous. This enables the operation of general-purpose equipment within the secure enclosure.

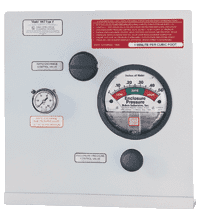

Enviro-Line Pressurization System

Enviro-Line purging units serve as an enclosure pressurization system for non-hazardous areas, operating on a supply of compressed instrument air or inert gas. They regulate and monitor the pressure within the sealed enclosure to prevent the accumulation of damaging and acidic gases and dust.

Key Features and Advantages of P+F Systems

Here are some features and advantages of Pepperl+Fuchs Purge systems.

Key features

- Pepperl+Fuchs purge and pressurization systems are designed as integrated solutions, including control units, solenoid valves, pressure sensors, and other components necessary for effective hazardous area protection.

- These systems often come with international certifications, such as ATEX and IECEx, ensuring compliance with global standards for hazardous area equipment.

- Pepperl+Fuchs systems feature user-friendly interfaces for configuration and monitoring. Intuitive controls and displays make it easier for operators to set up and maintain the system.

- The modular design allows for scalability, making it adaptable to various applications and enclosure sizes. This feature is beneficial for users with diverse industrial needs.

- Advanced diagnostic features and status monitoring capabilities provide real-time information on the system's performance. Users can quickly identify issues and take corrective actions.

- Pepperl+Fuchs pressurization system installation is designed with clear instructions and compatible mounting options. This can help reduce downtime during the implementation process.

- The systems are typically constructed with durable and corrosion-resistant materials to withstand the harsh conditions found in industrial environments.

- These systems are often designed to operate within a broad temperature range, making them suitable for installations in various climates and industrial settings.

Advantages

- Pepperl+Fuchs purge and pressurization systems contribute to a higher level of safety in hazardous environments by preventing the ingress of flammable gases or combustible dust into electrical enclosures.

- Compliance with international standards and certifications ensures that these systems meet the safety requirements of industries worldwide.

- The advanced monitoring and diagnostic features help minimize unexpected downtime by allowing users to proactively address issues before they lead to equipment failures.

- By maintaining a clean and safe internal environment within enclosures, these systems contribute to the longevity and reliability of electrical and electronic equipment.

- The modularity and scalability of Pepperl+Fuchs purge and pressurization systems make them suitable for a range of applications, allowing users to tailor the solution to their specific needs.

- While providing advanced features, Pepperl+Fuchs systems are designed to offer cost-effective solutions for hazardous area protection, helping organizations meet safety requirements without unnecessary expenses.