Pepperl+Fuchs Purge and Pressurization Systems

- Certified for Class I, Class II, Division I- Zone 1 / Zone 21 to nonhazardous

- Intrinsically safe electrical/pneumatic manifold assembly

- Intrinsically safe user interface for programming and monitoring the system

- Enclosure volume up to 450 ft3 (12.1 m3)

- Control Unit monitors system operation and controls enclosure power

- Universal mounting (brackets included)

- 316L stainless steel Type 4X enclosure

Purge&Pressurization

Purge&Pressurization

Purge &Pressurization

- Interface for field connection back to EPCU

- DIN rail mounting

- Easy termination of connections

- Removable terminal on EPCU side

- Allows for temperature sensing to automatically initiate cooling or heating of enclosure

- Intrinsically safe and loop powered with the 6000 Series control unit

- Suitable for Zone 1 and Division 1 mounting

- Four temperature points per hub

- Temperature control for purged/pressurized enclosures

- Remote sensor

- Suitable for Zone 1 and Division 1 mounting

- Intrinsically safe when used with the 6000 Series purge system control unit

- Easy mounting for temperature measurements up to 3 m from the temperature hub

- Automatic purge and pressurization system for most applications

- User-friendly, easy programming

- LCD screen for operation status and LED's for quick visual identification of system

- HART communication through RS485 with PACTware and device app's through Bluetooth

- Maximum enclosure size 12.75 cubic meters

- Compact design with panel mounts or direct mounts available

- Universal power 20 to 30 VDC / 100 to 250 VAC. 50 to 60 HZ

- Pressure, temperature, dilution control and monitoring

- Up to SIL 2 acc. to IEC 61508

- Automatic purge and pressurization system for most applications

- Universal power 20 to 30 VDC / 100 to 250 VAC. 50 to 60 HZ

- Up to SIL 2 acc. to IEC 61508

Purge&Pressurization

Purge&Pressurization

- Complete approved cable glands, plugs, and nuts for installation to the 6500 control unit

- Selection of material - stainless steel, nickel plated brass, or plastic

- ATEX/IECEx approved / II 2G 1D

- Must be used in conjunction with an EPV-7500-* vent

- External mount, rectangular box

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Manual valve, no electrical power requirement

- Purge and pressurization valving in one device

- Must be used in conjunction with an EPV-7500-* vent

- Panel mount, rectangular panel

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Manual valve, no electrical power requirement

- Purge and pressurization valving in one device

bebco purge

Gas supply:

- Volumetric gas flow rate: 0.001 to 100 l/min

- Maximum length of pipelines: up to 100 m

Controller:

- Type of control: analog, digital

- Availability of display: yes, no

- Availability of interfaces: RS485, Modbus, Ethernet

- Maximum enclosure size 450 ft3 (12.7 m3)

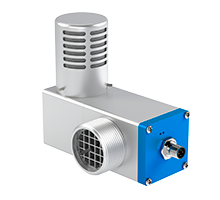

- Pressure relief vent with flow and pressure monitoring at the exhaust

- Universal mounting in any orientation

- 6000 Control Unit supports 2 vents

- Different vents for different applications

Purge&Pressurization

Purge&Pressurization

- One design, three flow rate variants to support your design requirements

- Anodized aluminum with an optional stainless steel cap

- Universal mounting

Purge&Pressurization