ABB ACS550 Common Fault Codes

21.12.2021

In the process of operation of the frequency converter, sooner or later problems related to its correct operation arise. Errors and failures can occur both when turning on (setting) the frequency converter and during its operation.

CONTENTS:

- Overcurrent, Overvoltage & Overload

- Heatsink Overtemp

- Short Circuit

- DC Undervoltage and AI-1/AI-2 Loss

- ID Run Fail

- Encoder Error and Motor Phase

There are two types of messages: warnings and failures.

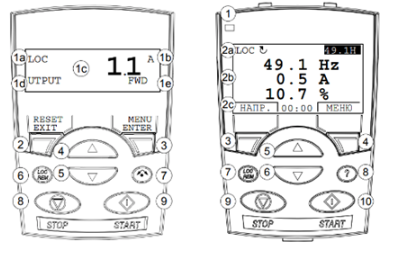

- Warning. The code is accompanied by the letter A (on the base panel) or the word abb drive alarm 2021 on the smart panel. They are displayed in case of non-emergency situations which are worth paying attention to. The warning is reset automatically if the cause is eliminated.

- Failure. The abb drive fault codes are followed by F (on the base panel) or FAULT (on the smart panel). If a fault occurs, the motor stops to avoid damage to the frequency converter itself or other equipment. To reset the failure, remove the cause of the failure, then, if the indicator flashes red on the panel or the frequency converter - disconnect the power supply from the frequency converter for 5 minutes and supply it again. If the indicator continuously lights red, it is necessary to press RESET on the control panel or disconnect the power supply from the frequency converter for 5 minutes and supply it again.

If most errors occur, the inverter stops working. The reaction to some errors can be programmed. For example, if a fault occurs the frequency converter can stop or continue to run by issuing a fault message. In some frequency converters, there is a so-called "fire mode", when the frequency converter works despite problems, up to breakdown and fire.

To begin with, let's look at the typical abb alarm 2021 and error messages of frequency converters, which are displayed on the user's screen. Note that most of abb vfd alarm 2021 messages are transmitted via the communication channel (if present) to the controller and handled accordingly.

ABB ACS550 frequency converters have incorporated all the latest research. This series of ABB frequency inverters guarantees the highest technical level, remarkable reliability characteristics, and ease of use. In the drive, the ACS 550 principle of vector control is used, which allows you to get the highest motor torque episode at low speeds and improves the quality of the scientific and technical process.

The ACS550 frequency converter is equipped with:

- built-in electromagnetic compatibility filter (EMC);

- depending on the power - choke with variable inductance on the cover of multiple current or choke on the input of the drive (allows to reduce to the maximum the level of interference generated by the converter and increases insensitivity to the instability of the mains);

- connection terminal box, allowing to make the attachment of cables to the body of the drive with the simultaneous grounding of the shields;

- a wide set of integrated defenses, allowing almost always avoiding the defect of the drive itself, the motor it controls, and the device;

- macros to control the external scientific and technical parameter using one of the two integrated PID controllers;

- 2 user macros and 8 stereotype macros;

- built-in program to control a pumping station with up to 4 pumps;

- built-in Modbus RTU protocol (RS-485 interface).

Overcurrent, Overvoltage & Overload

1. Code on the display: OC (Over Current). This message indicates that the frequency converter output current has exceeded the allowable value. If this error occurs the first time you start the frequency converter, you should check if the rated current of the frequency converter matches the actual motor current - a short circuit may have occurred inside the motor. In some types of frequency converter, OC overload can be divided into 3 different errors - overcurrent during acceleration, under braking, running at a constant speed.

2. Code on display: OL (Over Load). This message is related to the previous one and some extent duplicates it. The OL message may be caused by the internal electronic thermal motor protection, or by the motor being overloaded mechanically (over torque). The overload level is set when setting the frequency converter, and both the current level (in amperes or percent) and the response time in seconds are set.

3. Code on display: OV (Over Voltage). This message appears when the DC link voltage exceeds the allowable threshold. First of all this error occurs during braking when the motor is in the power generation mode. This problem can be solved in several ways - increase the braking time, apply a braking resistor, disable braking (stopping the motor at free coasting), raise the limit level of overvoltage limitation if possible.

Heatsink Overtemp

Code on display: DEV OVERTEMP. The drive heat sink is overheating. The temperature is higher.

Similar fault: OH (Over Heat). After abb vfd troubleshooting we get this code on the display. This message indicates the converter temperature is too high. The first thing to do is to check that the internal fans of the inverter are working properly and clean them with compressed air. Also, check the heat dissipation from the converter and the temperature and air circulation inside the control cabinet. It may be necessary to install additional cooling or to reduce the load.

We have listed only the main fault messages. Their number can be up to several dozens, which allows more accurate tuning of the converter operation and abb vfd ach550 troubleshooting. In different frequency converter models these messages can be indicated in different ways, for example, in the ProStar PR6000 frequency converter they look like Er01, Er02, etc., but the meaning is similar.

In several frequency inverter malfunctions, the messages are not displayed on the screen. Mainly, it is related to power supply problems or fatal faults in the frequency converter. In addition, if there are problems with the initial start-up, there is a possibility of an error in the connection of control circuits (start-up). Let's take a closer look at such malfunctions.

Short Circuit

Code on display: F0004 (FAULT 4) - short circuit.

Possible causes:

- Short circuit in the motor or motor cable(s);

- Interference in the mains.

DC Undervoltage and AI-1/AI-2 Loss

The inverters have two analog input contacts, of which AI 1 can only be used for voltage input and AI 2 for voltage and current input (if the number of input and output contact functions needs to be increased).

- Code on display: AI1 LOSS Analog input 1 loss.

- Code on display: AI2 LOSS Analog input 2 loss.

ID Run Fail

Code on display: ID RUN FAIL Engine run error has not been successfully executed.

Six operating parameters can be output: set frequency, real frequency, real motor current, percentage of current, DC bus voltage, output voltage, real motor speed, cumulative total running time, IGBT transistor temperature, PID set value, PID return value, status of terminal inputs and outputs, analog inputs AI 1 and AI 2, current segment number, torque set value.

Up to five error messages can be stored; if a fault occurs, fault type, voltage, current, frequency, and operating state can be queried.

Encoder Error and Motor Phase

Code on display: Encoder Error, F0023 (FAULT 23) - The frequency converter is not receiving the correct encoder signal;

Even though the presented frequency converter was designed to perform routine tasks in production, it has several advantages over its analogs. The key advantage of this model is simplicity and standard. Since no extraordinary goals are set for the device, the design is quite simple and unpretentious.

The drive is completed mainly with standard spare parts. This means that the time required for commissioning and the cost for repairs are kept to a minimum.

Thanks to standardized parts, installation is also no problem. Frequency controllers come already with built-in energy efficiency features.

Abb acs 550 frequency inverters generally have several nice design features:

- Built-in Modbus protocol.

- Availability of a special variable inductance choke.

- Variety of available power ratings from 0.75 to 355kW.

- The boards are protected with a special coating.

- Loads with variable and constant torque.

Also, the use of standard software in frequency converters can be attributed to the explicit advantages of the represented series. This somewhat simplifies the programming of the device. The devices are equipped with Fieldbus, which uses its protocol.

Eltra Trade offers a wide selection of ABB products. Our managers assist with selection and questions, ensuring fast worldwide delivery.