Decoding Endress+Hauser Promag 300 Fault Codes: Troubleshooting Guide

29.02.2024

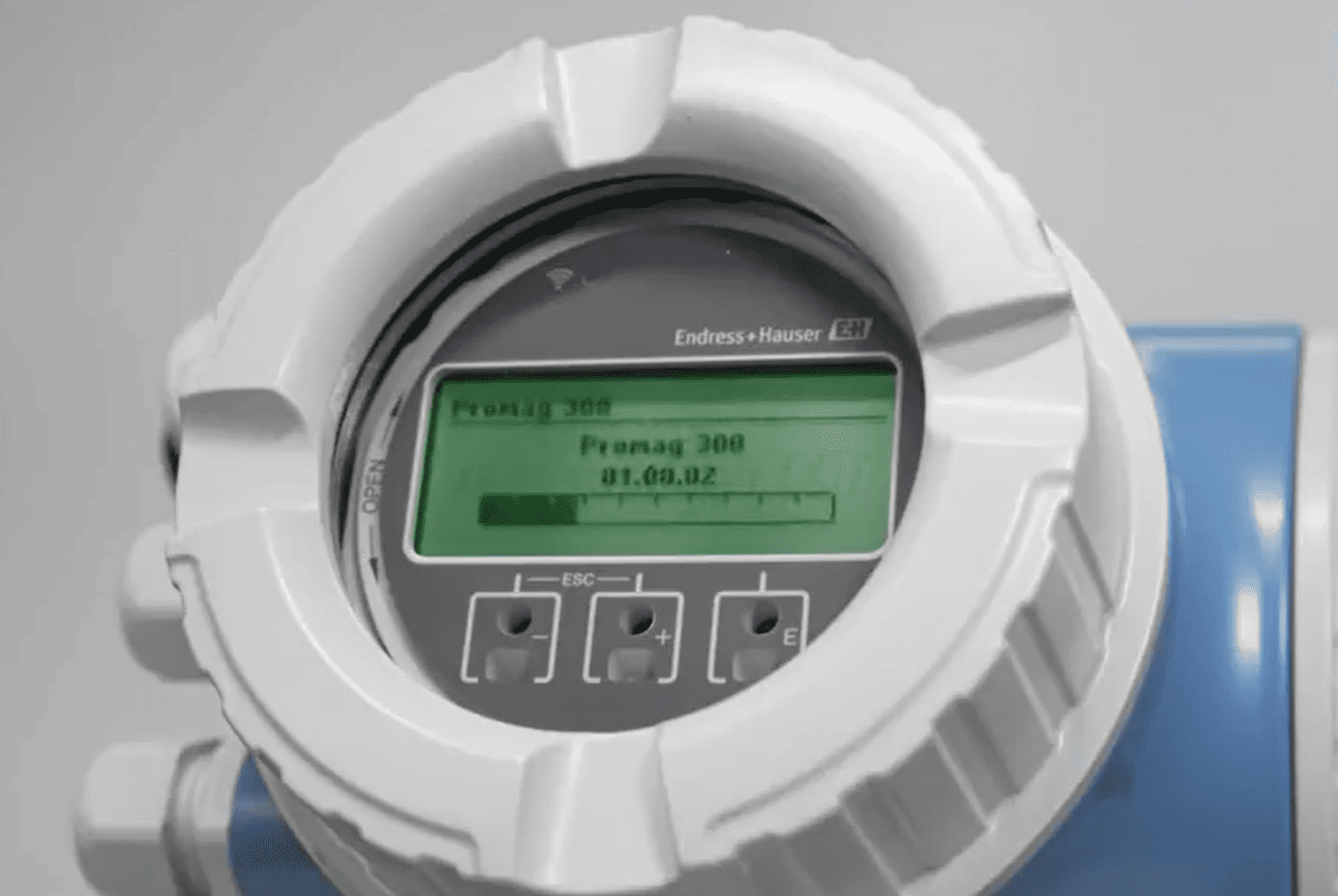

Endress+Hauser is a Swiss company producing industrial measurement devices. In particular, they produced electromagnetic flow meters. Like any other equipment, they can break down, and when the device malfunctions, you can often see errors shown on the display. Today we will talk in detail about Endress+Hauser Promag 300 fault codes.

Understanding Promag 300 Error Codes

Understanding Promag P 300 error codes is crucial for diagnosing and resolving issues with your equipment. These error codes typically provide information about specific faults or problems that the flowmeter has detected. Thus, when you find out the nature of the breakdown of your device, you can easily fix it. That is why below we will consider in detail all the codes and ways of solving Promag 300 faults.

Common Fault Codes and Their Explanations

Let’s continue our diagnostic guide for Promag 300 with common fault codes and their meanings.

Common fault codes for local display

| Error | Possible cause | Solution |

| Local display dark and no output signals. | The supply voltage does not match the value indicated on the nameplate. | Apply the correct supply voltage. |

| Local display dark and no output signals. | The polarity of the supply voltage is wrong. | Correct the polarity. |

| Local display dark and no output signals. | No contact between connecting cables and terminals. | Check the connection of the cables and correct if necessary |

| Local display dark and no output signals. | Terminals are not plugged into the I/O electronics module correctly. Terminals are not plugged into the main electronics module correctly. | Check terminals. |

| Local display dark and no output signals. | I/O electronics module is defective. Main electronics module is defective. | Order spare part |

| Local display is dark, but signaloutput is within the valid range | Display is set too bright or too dark. |

|

| Local display is dark, but signal output is within the valid range. | The cable of the display module is not plugged in correctly. | Insert the plug correctly into the main electronics module and display module. |

| Local display is dark, but signal output is within the valid range. | Display module is defective. | Order spare part. |

| Backlighting of local display is red. | Diagnostic event with "Alarm" diagnostic behavior has occurred. | Take remedial measures |

| Text on local display appears in a foreign language and cannot be understood. | Incorrect operating language is configured. | 1. Press “-” + “+” for 2 s ("home position"). 2. Press “E”. 3. Set the desired language in the display language parameter |

| Message on local display: "Communication Error" "Check Electronics" | Communication between the display module and the electronics is interrupted. |

|

Common fault codes for output signal

| Error | Possible causes | Solution |

| Signal output outside the valid range. | Main electronics module is defective. | Order spare part. |

| Signal output outside the valid current range (< 3.6 mA or > 22 mA) | Main electronics module is defective.I/O electronics module is defective. | Order spare part. |

| Device shows correct value on local display, but signal output is incorrect, though in the valid range. | Configuration error | Check and correct the parameter configuration. |

| Device measures incorrectly. | Configuration error or device is operated outside the application. | 1. Check and correct parameterconfiguration. 2. Observe limit values specified in the "Technical Data". |

Steps to Resolve Promag 300 Faults

Let’s discover some general steps that you can take to resolve common issues with Promag 300 fault codes:

- Ensure that the flowmeter is receiving the correct power supply. Check for any power-related issues, such as tripped circuit breakers or disconnected power cables.

- Check the wiring connections to the flowmeter. Make sure all cables are securely connected to the appropriate terminals and that there are no loose connections.

- Ensure that the flowmeter is properly grounded. Improper grounding can lead to electrical issues and signal interference.

- Verify that the flow profile is within the recommended limits for the Promag 300. Turbulence or uneven flow can affect the accuracy of the measurements.

- Check the condition of the electrodes. Inspect for any corrosion, coating, or damage. Clean the electrodes if necessary, following the manufacturer's guidelines.

- Make sure that the sensor is properly aligned with the flow direction. Misalignment can result in inaccurate readings.

- Review and verify the configuration settings of the flowmeter. Ensure that the parameters are set correctly for your application.

- Check if there are any available software or firmware updates for the Promag 300. Updating the firmware may resolve known issues or bugs.

- Perform a calibration if necessary. Regular calibration ensures accurate measurements. Follow the calibration procedures provided by the manufacturer.

- Refer to the user manual or technical documentation provided by Endress+Hauser for specific Endress+Hauser flow meter error codes troubleshooting information and guidelines.

Preventative Measures for Avoiding Faults

To prevent Endress+Hauser error codes from appearing and ensure the reliable operation of Promag 300 electromagnetic flowmeters, consider implementing the preventative measures that we list below.

Regular inspection and maintenance

Conduct inspections of the flowmeter system to identify any signs of wear, corrosion, or damage. Perform scheduled maintenance tasks as recommended by the manufacturer.

Electrode cleaning

Periodically clean the electrodes to remove any buildup of deposits or coatings. Follow the manufacturer's guidelines for proper cleaning procedures.

Flow profile consideration

Design and install the flowmeter in a way that ensures a stable and well-defined flow profile. Turbulence or uneven flow can affect the accuracy of the measurements.

Proper installation

Follow the manufacturer's installation guidelines and recommendations. Ensure that the flowmeter is correctly installed, including proper alignment with the flow direction.

Environmental conditions

Protect the flowmeter from extreme environmental conditions, such as excessive heat, cold, humidity, or corrosive substances. Install the flowmeter in suitable conditions specified by the manufacturer.

Avoid physical damage

Take precautions to prevent physical damage to the flowmeter. Install protective measures, such as barriers or guards, to avoid accidental impact or contact.

Monitoring and alarming

Implement a monitoring system with alarms to alert operators to any abnormal conditions or faults. This allows for prompt intervention and preventive action.

Training and awareness

Ensure that personnel responsible for operating and maintaining the flowmeter are adequately trained. Knowledgeable operators are better equipped to identify potential issues early and take corrective actions.

Documentation and record-keeping

Maintain detailed records of installation, calibration, maintenance, and any issues encountered. Documentation can aid in troubleshooting and provide a historical perspective on the flowmeter's performance.

Expert Tips for Troubleshooting Promag 300 Issues

Process instrumentation troubleshooting with Promag 300 electromagnetic flowmeters may require a systematic approach. Here are some expert tips for troubleshooting common problems.

- Start Promag 300 troubleshooting by reviewing the user manual and technical documentation provided by the manufacturer. Familiarize yourself with the operational principles, installation requirements, and troubleshooting guidelines specific to the Promag 300 model.

- Verify that the flowmeter is receiving the correct power supply. Check for any power-related issues, such as voltage fluctuations or inadequate power. Ensure that the power supply is stable and within the specified range.

- Examine all wiring connections to ensure they are secure and correctly configured. Check for loose or damaged cables and make sure they are properly connected to the appropriate terminals.

- Confirm that the flowmeter is properly grounded. Inadequate grounding can lead to electrical issues and signal interference. Address any grounding problems to ensure a stable electrical environment.

- Inspect the condition of the electrodes. Look for signs of corrosion, coating, or damage. Clean the electrodes following the manufacturer's guidelines. Ensure proper alignment of the sensor with the flow direction.

- Evaluate the flow profile and ensure it meets the recommended conditions for the Promag 300. If there are issues with turbulence or uneven flow, consider adjustments to the installation or piping.

- Utilize any built-in data logging or diagnostic features of the flowmeter. Analyze historical data to identify patterns or anomalies that could help pinpoint the cause of issues.

- Check communication protocols and output signals. Verify that the flowmeter is communicating properly with any connected devices or systems. Troubleshoot issues related to signal output or data transmission.

- If troubleshooting efforts do not resolve the issue, contact the manufacturer's technical support. Provide them with detailed information about the problem, steps taken, and any error codes or messages received.