Different types of solenoid valves

13.06.2021

Flow control of liquid or gaseous solutions or environments has long been carried out not only mechanically. Modern industrial enterprises are constantly upgrading the main devices to meet all requirements and standards. So, in recent years, so-called solenoid valves are increasingly used for industrial purposes. A solenoid valve is understood as a device that serves to regulate the direction of movement of gas or liquid flows in various technological systems. The solenoid valve works automatically and is controlled by an electric current that is supplied to the induction coil included in the solenoid valve.

CONTENTS:

- What Is a Solenoid Valve?

- How Does a Solenoid Valve Work

- Area of Use of a Solenoid Valve

- Varieties of Solenoid Valves According to Their Internal Structure

- Solenoid Valve Options According to Their Operating Principle

- What Are the Solenoid Valves by Type of Seal and Diaphragm?

- Conclusions

What Is a Solenoid Valve?

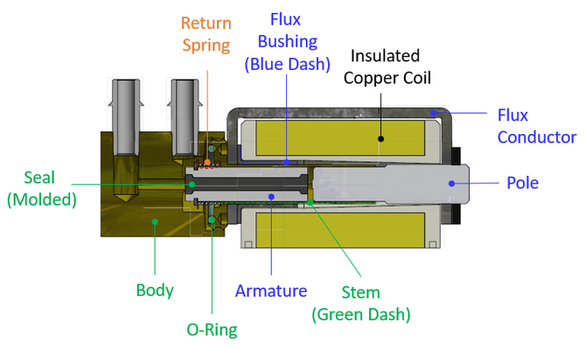

An electromagnetic (solenoid) valve is a device for controlling a working medium under pressure in a pipeline. Its main task is to open/close the bore with a plunger, which is influenced by the magnetic field of an electromagnetic coil or amplification due to the pressure of the working medium and the diaphragm.

The main components of a solenoid valve's constructions are the following:

- The valve body, which consists of an inlet, an outlet, and a seat.

- A reinforcement tube with a core on which the coil is mounted.

- Plunger that slides inside the reinforcement tube and, in some cases, serves as a seal.

- The electromagnetic coil, which creates a magnetic field necessary to move the plunger.

How Does a Solenoid Valve Work?

The copper induction coil, which is located inside the closure device, is hermetically sealed to prevent vapor, liquid or gas particles from entering. When it is necessary to open or close the flow channel of the working medium, the retractable stem solenoid and the diaphragm are used.

In the absence of current, under the influence of spring, the valve completely blocks the flow channel of the working medium or, on the contrary, leaves it completely open. After the voltage is applied to the coil, the cored rod is displaced, resulting in an increase or decrease in the flow cross-section.

In general, for all types of solenoid valves, the operating principle is very simple: the movement of the stem is carried out by the action of electromagnetic induction. When an electric current flows through a coil, an electromagnetic field is applied to the core at its center. The strength and direction of this field depend on the applied voltage. As a result, the shut-off element of the valve moves and the flow area of the channel increases or decreases.

Area of Use of a Solenoid Valve

The use of different types of solenoids is possible in various fields because their design is created taking into account a specific environment. The selection of solenoid valves is performed according to their application area.

Depending on the modification, the solenoid valve coil can operate with an operating voltage of 5 to 35 V DC or 220 V AC. Low-voltage solenoid valves are designed to operate in pipelines with a small diameter and low pressure inside the working medium. Their scope is rather limited. It is convenient to integrate such valves into low-voltage control systems, connect to various microcontrollers. Often they are used in private households to connect and control water supply and heating circuits.

In industrial enterprises, different types of solenoids are used almost everywhere including the following areas:

- Oil refineries and gas enterprises;

- Water, gas and heat supply systems;

- Ventilation and air conditioning systems;

- Sterilizers and irrigation systems:

- Pipelines serving food production, systems for bottling beverages, oils, liquid substances.

The scope of application is quite extensive, therefore, the design features of each type are adjusted to a specific area of operation. Each type of solenoid valve is designed to work with a specific medium, temperature ranges and pressures. Care must be taken when selecting a solenoid valve. If you are not sure which type you need, Eltra-Trade employees will help you decide and advise on all your questions.

Depending on their connection type, all solenoids are divided into three main types:

- Flange solenoids;

- Clutch solenoids;

- Choke solenoids.

As for their sizes, there are lots of diameter options suitable for almost every pipe diameter from 1/8'' to 6''. The body of each solenoid valve could be made of the following materials:

- PPA/PVC/nylon;

- Stainless steel;

- Brass;

- Cast iron.

Every type of material has its own durability, temperature and pressure features that should be taken into account.

Varieties of Solenoid Valves According to Their Internal Structure

By design, all solenoid valves are divided into three main types:

- Poppet solenoid valves,

- Diaphragm ones,

- Piston valves.

Solenoid diaphragm valves are the most common choice for household applications. They are installed on water supply systems and heating circuits when introducing automation, including smart home systems.

If we consider all these valves by the position of their closing element with de-energized solenoid of the coil, there are three basic types:

- Normally closed valve. Until the solenoid is energized, the spring presses on the core, and the working medium is closed.

- Normally open valve. In it, on the contrary, when energizing the solenoid, the working medium is opened.

- Bistable, working in both options.

Solenoid Valve Options According to Their Operating Principle

If we talk about the operating principle, there are two major options of solenoid operated valve.

- Indirect solenoid valve. This type of valve is available with connection sizes from 1/4 " to 3". With large diameters, the static pressure of the working medium increases, and it is necessary that the magnetic field created by the coil be able to cope with it. This is achieved through the use of a servo-controlled action in the valve. With this design, the medium pressure helps maintain the seal on the main valve.

- Direct-acting solenoid valve. The two-way valve has an inlet and outlet connection in the body. This type can work with 0 pressure level.

By their acting, solenoid valves of any voltage can be:

- A single-acting solenoid valve with one branch pipe for connection to the pipeline. It is used as safety elements for the rapid release of steam or liquid at too high a pressure.

- Double-acting solenoid valves are the most popular as they have two branch pipes both for entering and exit of the flow. They are placed in pipeline ruptures to connect two pipes into the line.

- Triple-action valves are an important element in heating systems. Thanks to them, you can easily redirect the flow of water or gas from one circuit to another.

What Are the Solenoid Valves by Type of Seal and Diaphragm?

When we talk about the diaphragm type of solenoid, there are also several options available. The solenoid valve diaphragm is located inside the housing to shut off the fluid flow. In addition, a sealant layer is usually laid between the coil and the nozzles. In terms of their composition, both of these components are made of polymer materials. So, the seal is usually made from:

- EPDM that is an inexpensive polymer resistant to salts, acids and alkalis,

- FPM that is resistant to oils, gasoline, with the widest range of operating temperatures,

- NBR is an oil-tolerant polymer.

Based on the scope of application, it is worth paying attention to the type of seal in the valve. The membrane is selected in the same way.

Conclusions

The range of solenoid valves on the market is extremely wide. And it is worth choosing workable and reliable components, relying on several key characteristics at once. This is the type of connection, design features, the principle of operation, number of nozzles, material of the valve itself and its seal and membrane.

In order to get reliable solenoids, it is better to buy them at the Eltra-Trade store. We work with the best manufacturers of industrial equipment and are always ready to help you with the selection of solenoid valves for your pipeline.

We offer at the best prices: Burkert solenoud valves, Univer valves and other brands.