Encoder working principle

19.06.2022

The encoder can be found in a printer, subway, airplane, streetcar, construction crane, elevator, even on an advanced garden plot as a gate opening sensor. Let's take a closer look at the product that is widely used in the automation of industrial processes.

What does the word encoder mean?

Three types of encoders can be used to measure the angle of rotation: Absolute position, an incremental encoder with "1" or "0" output, and incremental sine encoder. The absolute angle encoder is based on a disk divided into several segments with different patterns. For example, there are 8 segments for a 3-bit signal.

- The absolute encoder tracks its position by providing information from the moment the power is turned on. This is useful when the machine is not in use all the time and the power is off at that time.

- The rotating incremental encoder disc generates a digital pulse signal. It also has a reference mark to indicate the current rotational position, indicating the zero angle. The reference pulse, commonly referred to as the "Z" pulse, uses photodetectors electronics to determine the exact reference position once per revolution, generating "quadrature" signals that form two pulse streams, A and B, offset in time by 90 to each other. The sequence in which they are generated makes it possible to recognize the direction of rotation of the motor as measured. Some encoders also produce inverse pulses.

- An incremental encoder with a sinusoidal signal generates a sinusoidal signal. It generates a sine wave, a cosine wave, and a reference mark which are processed in electronic circuitry. These signals are quite different from the amplitude modulated sine wave converter signals. Encoder signals are much higher in frequency and do not contain a "carrier frequency".

Which encoder is the most useful

Let's take the motor as an example: The motor is of course the basis, but many control systems require that the information about the angular position of the motor is also very precise. The control algorithm loop takes the feedback signal from the position sensor to control the current in the motor at each stage of its operation. This control is based on independent control of the IGBT transistors feeding the windings of each of these phases, which results in regulation of current and therefore motor rotation.

Let's take the motor as an example: The motor is of course the basis, but many control systems require that the information about the angular position of the motor is also very precise. The control algorithm loop takes the feedback signal from the position sensor to control the current in the motor at each stage of its operation. This control is based on independent control of the IGBT transistors feeding the windings of each of these phases, which results in regulation of current and therefore motor rotation.

Resolvers coupled to motors operate at high temperatures and under heavy shock loads. Place the electronic motor control circuitry away from the motor's magnetic field and interference. On the other hand, the electronic circuits for encoder signals, because of the need for shorter connections, must be placed close to the encoder, which increases the temperature of their operation.

The resolver windings (usually 6 turns in the encoder) require good insulation due to the relatively high voltage applied to the motors, usually above 300V. The resolver must also withstand high temperatures. Its feedback circuits can withstand temperatures in excess of 125C, making the resolver the preferred solution for automotive and industrial applications in the harshest environments.

The absolute position sensor continuously signals the actual rotational position of the units. Resolvers produce unique sine and cosine voltage signals at each 360 position, which is why they are absolute position sensors. A digital encoder signal, on the other hand, can be absolute or incremental. Absolute encoders send data over a serial data bus such as SSI (synchronous serial interface). The controller must communicate with the drive unit according to this protocol.

The absolute position sensor continuously signals the actual rotational position of the units. Resolvers produce unique sine and cosine voltage signals at each 360 position, which is why they are absolute position sensors. A digital encoder signal, on the other hand, can be absolute or incremental. Absolute encoders send data over a serial data bus such as SSI (synchronous serial interface). The controller must communicate with the drive unit according to this protocol.

Incremental encoders do not provide absolute information and can only be used to increase or decrease the position counter. An incremental encoder does not retain position information after a power failure, even if the memory in the circuit is non-volatile.

Users of powerful motors used in transport applications prefer resolver encoders in practice because vibrations and strong shocks remain under control during position detection. Their copper windings in plated transformer cores in heat-resistant steel housings are environmentally resistant. And encoders consist of optoelectronic optical glass systems in epoxy-coated plastic housings and are environmentally sensitive. Because of shock and vibration, the accuracy of encoders there is lower than that of resolvers. The transparent optical disk used in an optical encoder is susceptible to dust contamination, despite safety precautions.

To increase resistance, encoder manufacturers use plastic or metal discs and other more heat-resistant components instead of glass. Mechanical insulation, as well as dust and grease protection, are used to increase resistance to shock and vibration. Resolvers are available as separate components, rotor, and stator, making them easy to connect to units.

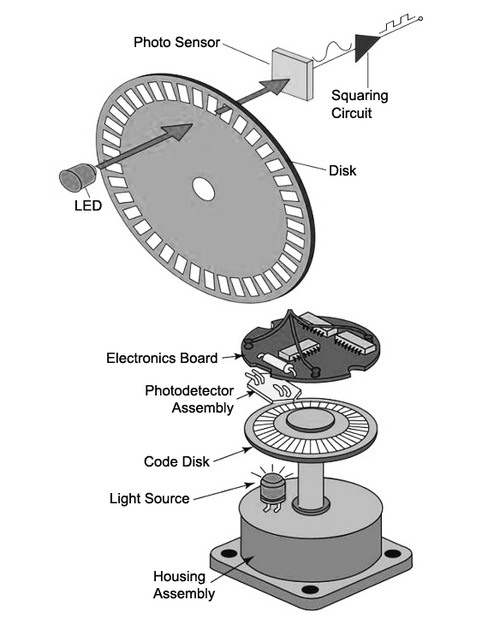

What are optical encoders: Working principle

How encoders work: Optical methods are quite popular in auto electronics because the principle is simple and the accuracy is better than the electrical methods. It is the underlying principles of encoder technology that ensure high accuracy, the ability to give digital information, stability, and noise immunity. It is an optical technology that offers several classic ways to build an encoder, a sensor that provides information about movement, position, or direction, either directly in digital form, or by generating a train of pulses that can be digitized to create a digital optical encoder.

The main applications of optical encoder applications are:

- Absolute angular position, torque, and speed sensors in drive-by-wire EPAS (electrically power-assisted steering), EHPAS (electro-hydraulic power-assisted steering), ESP electronic vehicle control systems;

- ambient light sensor for automatic adjustment of lighting parameters of LCDs (controlling backlighting current level and extending service life)4

- optical sensors for passenger detection, measuring the distance between the passenger and the airbag module (optimizing the airbag filling speed depending on the weight and position of the seat and the severity of the accident)4

- CMOS cameras for passenger position detection, rear cameras;

- Rain Sensor for monitoring the windshield wipers (reflective sensor detects raindrops on the windshield);

- electrochromic mirrors;

- Sun Load Sensors and Sun Load Sensors/Auto Light Sensors (to enable automatic air cooling);

- Belt Pretensioner Sensors and Seat Position Sensors in automatic position encoder control systems (light-frequency and light-voltage transducers, linear arrays);

- door closing control;

- LED color correction (TCS230 LED color-to-frequency converter);

- adaptive systems of front light, automatic switching on, and control of headlights intensity (HUD);

- control of vehicle interior lighting;

- carbon monoxide detection;

- optical identification systems;

- laser systems for obstacle detection and distance determination, radar, video sensors, etc.

You can find full catalog of Baumer encoders, Eltra, Sick, Pepperl+Fuchs, Siermens and other brands at our web store. We provide the best prices and customer support.