Inductive Proximity Switch Working Principle

31.10.2022

Proximity sensors are detectors that convert a physical quantity into a signal. Powered primarily by infrared filters, there are several types available for different purposes, all deployed in different areas.

Today we will learn what a proximity sensor is and also the proximity sensor working principle.

How Do Proximity Sensors Work?

Proximity sensors are devices that detect nearby objects even if there was no physical contact between the sensor and the object in question. Let's find out how is inductive sensor working.

The detector will send a signal as long as the object in question is in a certain proximity. Proximity sensors also function by converting information about the movement or presence of an object into an electrical signal, known as proximity sensors. Let's first get acquainted with what an inductive proximity switch looks like.

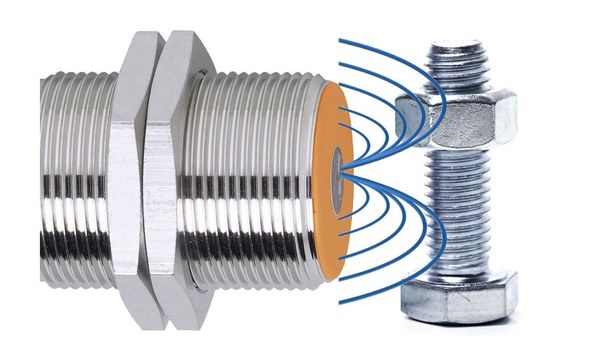

Let's first get acquainted with what an inductive proximity switch looks like.

The inductive proximity switch works differently when in contact with ferrous and non-ferrous metals.

An inductive proximity switch generates a high-frequency magnetic field on its front surface through its internal oscillation circuit. Ferrous metal is easily magnetized when ferrous metal approaches it, and the magnetization process absorbs the energy of the high-frequency magnetic field.

As ferrous metal approaches the proximity sensor, the more magnetized the metal is, the more energy is absorbed by the high-frequency magnetic field. This causes a load on the oscillatory circuit inside

The detection circuit inside the proximity sensor detects changes in the state of the oscillation circuit, thereby changing the state of the output and changing the value of the proximity switch signal from 0 to 1.

When non-ferrous metals (such as aluminum, copper, etc.) are near the inductive proximity switch, they do not absorb the energy of the high-frequency magnetic field. Conversely, such metals can also increase the frequency of the oscillatory circuit inside the proximity sensor. The internal detection circuit also detects this change, which changes the state of the output by changing the proximity switch signal value from 0 to 1.

Proximity Sensor Working Principle

Let's look at the inductive sensor working principle. Capacitive and inductive sensors are able to detect the presence of an object without direct contact with it. At the same time, inductive switches are sensitive only to metal objects, while capacitive ones are able to detect any objects whose dielectric constant is different from the air (for example, water, wood, metal, plastic, and so on). Consider the principle of operation of each sensor separately.

The main element of an inductive sensor is an inductor. It is connected to a generator. An alternating electrical voltage at its terminals causes an alternating magnetic field. The field lines will be perpendicular to the direction of the current in the turns of the coil.

In the absence of metal objects near the coil, the magnetic field lines are closed through the air. And the amplitude of electrical oscillations will be maximum.

If a metal object is brought closer to the coil, then an increasing part of the lines of force will begin to close through it. The inductance of the coil will begin to increase. This process is similar to the core insertion process. In this case, an increase in inductance will lead to a decrease in the amplitude and/or frequency of oscillations.

If such a system is equipped with a detector, then by changing the signal amplitude one can judge the presence of a metal object, its approach, or removal.

The operation of a capacitive sensor, as the name implies, is based on the use of capacitive couplings. The sensor itself, in fact, is one of the plates of a spatial capacitor. The second layer is the earth. The dielectric is predominantly air. Since the dielectric constant of air is small, the capacitance of such a capacitor is small. If some object with a higher value begins to approach the sensor, then the total capacitance will begin to increase.

Types of Proximity Sensors

Most popular types of proximity sensors are inductive and capacitive ones.

Inductive Proximity Sensor

Inductive type proximity sensors generate an output signal or electrical signals as soon as a metal object enters or near its detection zone from any specified direction. The metal objects that can be detected include iron, aluminum, brass, copper, and so on. Each of them can be detected at different detection distances.

For these types of sensors, flat targets are preferred, and targets that are larger than the sensing surface may increase the detection distance.

Capacitive Proximity Sensor

Next, we will understand what capacitive proximity sensors are. These proximity sensors can detect metals, but they can also detect resins, powders, liquids, etc. The way this sensor works may vary depending on the coating material, cable length, and noise sensitivity. The detection distance may also vary depending on factors such as temperature, the object to be detected, the surroundings of the object, and the distance between the sensors. The maximum operating range is 25mm.

Advantages of Inductive Proximity Sensors

Inductive sensors have proven themselves for many years as a reliable and durable tool for monitoring the presence of an object, and are used in a large number of technological and industrial processes in enterprises around the world.

Among the advantages of inductive proximity sensor it is worth highlighting:

- the high degree of reliability due to the simplicity of design and the absence of mechanical parts;

- convenience and ease of installation, in the absence of components requiring fine-tuning;

- the possibility of using in electrical networks with industrial frequency;

- high sensitivity.

Disadvantages of Inductive Proximity Sensors

Of the few disadvantages of inductive sensors, the main one is the dependence of the accuracy of the sensor on voltage, which necessitates a stable power supply. In addition, as in the case of any other electrical equipment, various factors can provoke a number of errors in the operation of inductive sensors:

- electromagnetic - usually taken into account as a random variable. It arises as a result of the influence of external magnetic fields on an induction coil when an EMF is induced in it;

- temperature - usually expressed as a percentage of the response distance and reaches about 10% of it. Determines the maximum deviation of the sensor's trigger point for temperature differences within the specified allowable range;

- deformation - may be a consequence of the occurrence of backlash at the installation site of the sensor or damage to its body while maintaining performance;

- cable - occurs when there is interference from external EMF fields in the connection cable, as well as during mechanical or thermal deformation of the cable;

- production - appears in case of deviations in the sensor production process at all its stages. For high-volume sensors, it is usually negligible.

Applications of Inductive Proximity Sensors

The fields of application of inductive sensors are practically unlimited. The main ones should include:

- industrial equipment - assembly and packaging lines, conveyors, as well as control devices for elements of industrial equipment (flags, gear teeth ...) and production facilities (any metal objects). In combination with impulse counters, an inductive encoder can serve as a simple and effective counting tool, and when used with a gear wheel, as a speed control sensor;

- automotive and railway equipment - to control the position of the crankshaft, opening / closing doors, the position of the folding body, etc.;

- household appliances - as well as devices for controlling the opening / closing of doors, and taps, as well as a part of "smart home" systems;

The high degree of protection of most inductive sensors allows them to be used in the most difficult conditions, including outdoors, and various special designs provide applicability in metallurgy, hydraulics, and the food industry.

Eltra Trade offers a wide selection of inductive sensors from leading companies like Baumer, Sick, Pepperl+Fuchs and IFM. Our expert managers are always ready to assist with selection and answer questions. We provide worldwide delivery and the best prices for regular and new customers!