Micromaster 440 fault codes

27.10.2023

Siemens is one of the world's largest electronics manufacturers. The company was founded in 1847 and today occupies a leading position in the market. In particular, the company will launch a VFD. Micromaster 440 is a model from the popular range of drives. But any electronics can fail. Therefore, today we will consider Siemens Micromaster 440 fault codes.

Micromaster 440 Fault Codes

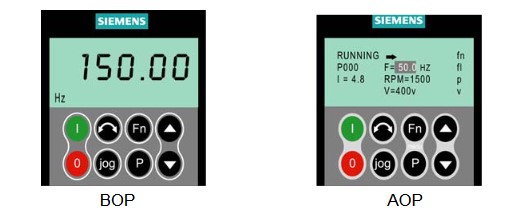

If your device has ceased to function correctly, then you need to look at the display where you will see Micromaster 440 fault codes which we have briefly described below.

- F0001 - Overcurrent.

- F0002 - Overvoltage.

- F0003 - Undervoltage.

- F0004 - Converter overheating.

- F0005 - I2t exceeded.

- F0011 - Engine overheating by I2t.

- F0041 - Error when measuring stator resistance.

- F0051 - Parameter error in EEPROM.

- F0052 - Stack error.

- F0060 - No response from the dedicated ASIC board.

- F0070 - Error setting via a communication board.

- F0071 - No data on the subsequent protocol (RS232) during the timeout.

- F0072 - No data on the subsequent protocol (RS485) during the timeout.

- F0080 - No input signal at the analog input.

- F0085 - External failure.

- F0101 - Stack Overflow.

- F0221 - PI controller feedback is below the minimum value.

- F0222 - Feedback of the PI controller is above the maximum value.

- F0450 (only in service mode) - Error during BIST testing.

- A0501 - Load current limitation.

- A0502 - The upper limit of the supply voltage has been reached.

- A0503 - The lower limit of the supply voltage has been reached.

- A0504 - Converter overheating.

- A0505 - Exceeding I2t.

- A0506 - Converter load cycle.

- A0511 - Engine overheating by I2t.

- A0600 - Real-time operating system overload.

- A0700 - CB warning.

- A0701 - CB warning 2.

- A0702 - CB warning 3.

- A0703 - CB warning 4.

- A0704 - CB warning 5.

- A0705 - CB warning 6.

- A0706 - CB warning 7.

- A0707 - CB warning 8.

- A0708 - CB warning 9.

- A0709 - CB warning 10.

- A0710 - CB communication error.

- A0711 - CB configuration error.

- A0910 - Vdc-max controller deactivated.

- A0911 - Vdc-max regulator active.

- A0920 - Analog input parameter set incorrectly.

- A0921 - Analog output parameter set incorrectly.

- A0922 - No load connected to the drive.

- A0923 - Jog to the right and Jog to the left (JOG) signals are active.

Resolving Micromaster 440 Fault Codes

Next, let's find out how to fix Micromaster 440 common fault codes.

F0001

Check motor and inverter power matching.

Check that the length of the power cables does not exceed the permitted length.

Check the motor and its wires for short circuits and ground faults.

Check that the entered motor parameters correspond to the actual parameters of the connected motor.

Check stator resistance (P0350).

Increase the acceleration time (P1120).

Reduce boost voltage in parameters P1310, P1311, and P1312.

Check if the motor is overloaded or stuck.

F0002

Check if the supply voltage is within the limits indicated on the rating plate.

Check if the DC link voltage regulator (P1240) is activated and correctly parameterized.

Increase the deceleration time (P1121).

F0003

Check if the supply voltage is within the range indicated on the rating plate.

Check for temporary network outages or network failures.

F0004

Check if the built-in fan rotates when the drive is running.

Check if the modulation frequency is set to the default value.

The ambient temperature has exceeded the value allowed for this transmitter.

Check if the air inlet and outlet areas are closed.

F0005

Check if the load duty cycle is within acceptable limits.

Check motor and inverter power matching.

F0011

Check if the temperature constant of the motor is entered correctly.

Check the parameter where the overtemperature warning limit is set.

Check engine load.

Reduce the values of parameters P1310, P1311, and P1312.

F0041

Check if the motor is connected to the inverter.

Check that the motor data has been entered correctly.

F0051

Reset the drive to factory settings and set the parameters again.

Replace converter.

F0052

Repair or replace the converter.

F0060

Reset the error.

If it persists, replace the converter.

F0070

Check communication with the communication board.

Check the master on the bus.

F0071

Check communication with the communication board.

Check the master on the bus.

F0072

Check communication with the communication board.

Check the master on the bus.

F0080

Check the analog input connection.

F0085

Disable fault latching through input terminals.

F0101

Run the self-test procedures.

Replace converter.

F0221

Change the value of parameter P2268.

Adjust the feedback factor.

F0222

Change the value of parameter P2267.

Adjust the feedback gain.

F0450

The inverter can be started, but some functions will not work correctly.

Replace converter.

Diagnostic Steps for Micromaster 440 Fault Codes

And now let's find out how to correctly diagnose Siemens drive Micromaster 440 fault codes.

- Identify the fault code.

- Check out the guide.

- Inspect the motor and connections.

- Check input power.

- Make sure that the current drawn by the motor is within the rated current.

- Ensure proper ventilation and cooling of the drive.

- Assess the load on the engine.

- View the drive parameter settings.

- Make sure the VFD and motor are properly grounded.

- Check the control signals (analog or digital) going to the VFD. Check that the VFD software and firmware are up to date.

Tips for Troubleshooting Micromaster 440 Faults

Now we will move on to learning tips on how to fix, for example, Siemens Micromaster 440 fault code a0503.

- Familiarize yourself with VFD fault codes and their meanings by referring to the user manual or the technical documentation provided by Siemens.

- Gather as much system information as possible, such as drive specifications, before you begin troubleshooting.

- Ensure the power to the VFD and associated equipment is off before troubleshooting.

- Check all external connections, including power supply, motor connections, control signals, and communication cables. Make sure they are secure and properly installed.

- Check the Micromaster 440 status LEDs.

- Check the input voltage and frequency of the VFD. Incorrect power supply settings may cause malfunctions.

- Check the VFD parameter settings for the recommended values in the user manual.

- Ensure the VFD and motor are correctly grounded and the control cables are properly shielded to minimize electrical noise.

- Assess the motor load conditions and make sure the VFD is suitable for the application.

- Inspect the engine for signs of damage, overheating, or mechanical problems. A faulty motor can cause failures in the VFD.

- Check the temperature of the VFD during operation. Overheating may cause malfunctions. Provide adequate ventilation and cooling.

- If you encounter an error you are unsure of or cannot resolve, please refer to the VFD user manual and Siemens technical support for further guidance.

Explore our extensive inventory of Siemens Drives products. Our managers offer expert guidance and ensure rapid worldwide delivery.