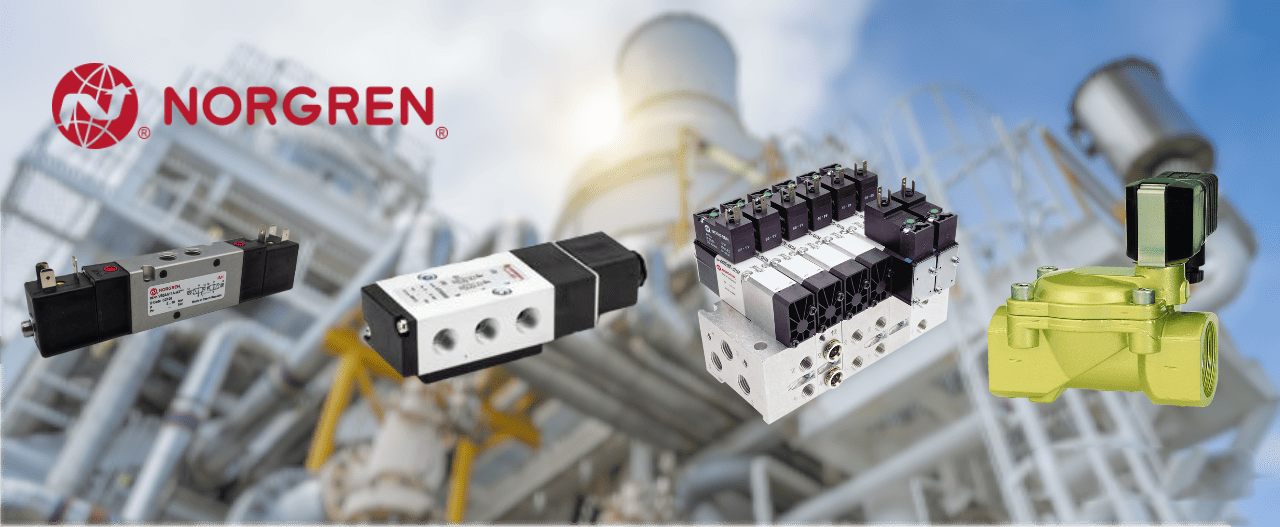

Norgren solenoid valves for perfect flow control

07.06.2024

In the ever-evolving world of industrial automation, the need for precise and reliable control mechanisms is paramount. Among the myriad of components that drive these sophisticated systems, solenoid valves stand out as essential elements. A well-known leader in fluid and motion control systems worldwide, Norgren provides a wide selection of solenoid valves made to satisfy the various needs of contemporary industry. Whether you’re involved in manufacturing, automotive, medical, or any other industry that relies on automation, understanding the capabilities and benefits of Norgren solenoid valve can help you optimize your systems for peak performance.

An Overview of the Brand Norgren

Norgren, part of the IMI Precision Engineering group, has established itself as a leading name in the field of industrial automation. With over a century of expertise, Norgren is synonymous with high-quality fluid and motion control solutions. The brand's unwavering commitment to innovation and excellence has made it a trusted partner for industries worldwide.

Norgren, part of the IMI Precision Engineering group, has established itself as a leading name in the field of industrial automation. With over a century of expertise, Norgren is synonymous with high-quality fluid and motion control solutions. The brand's unwavering commitment to innovation and excellence has made it a trusted partner for industries worldwide.

Norgren solenoid valve catalogue is extensive, encompassing a wide range of automation components, including pneumatic actuators, air preparation products, fittings, and solenoid valves. The company's solutions are designed to improve efficiency, safety, and reliability in various applications, from manufacturing and automotive to medical equipment and food processing.

One of Norgren's standout attributes is its dedication to research and development. By continually investing in cutting-edge technologies and materials, Norgren ensures its products meet the evolving demands of modern industry.

Basic Functionality of Solenoid Valves

The flow of gases or liquids is controlled by an electromechanical solenoid valve. Its two main components are an electric coil, or solenoid, and a valve body. When an electric current passes through the solenoid, a magnetic field is produced, which causes an armature or plunger to actuate, opening or closing the valve. Because of its simple yet effective operation that allows for exact control over fluid flow, solenoid valves are essential parts of many automated systems.

Specific Features of Norgren Solenoid Valves

Norgren valves are renowned for their durability, precision, and versatility. These valves are designed to meet the stringent requirements of diverse industrial applications. Here are some key features that set Norgren solenoid valve apart.

- Robust Construction: Engineering plastics, stainless steel, and brass are among the premium materials used in the construction of Norgren solenoid valves. This guarantees resilience to corrosion and longevity, even in challenging conditions.

- High Flow Rates: These valves are designed to offer the best possible flow rates, guaranteeing effective operation in a range of settings.

- Low Power Consumption: Solenoid valves Norgren are designed to minimize energy consumption, contributing to overall system efficiency and cost savings.

- Versatility: With a wide range of configurations, Norgren solenoid valves can handle different types of fluids and gases, making them suitable for various industrial uses.

- Ease of Maintenance: These valves are designed for easy installation and maintenance, with accessible components that simplify routine checks and repairs.

Types of Norgren solenoid valves

Norgren offers a wide range of solenoid valves to suit different needs and applications. Here are some of the most popular types.

1. Norgren air control valve.

- Norgren RA: These valves are designed for precise regulation of air flow in pneumatic systems. They are available in a wide range of configurations, including manual, pneumatic and electric control options.

- Norgren RE: These valves work to regulate air pressure in pneumatic systems. They have a compact design and high accuracy of adjustment.

2. Distributors of electromagnetic valves.

- Norgren PNEU-STAR: These modular distributors offer the flexibility and convenience to control multiple pneumatic valves from one location. Available in different configurations with different number of ports and control options.

- Norgren VIP: These compact and lightweight dispensers are ideal for confined spaces. They offer high performance and reliability.

3. IMI Norgren solenoid valves.

- Norgren 2-Position Valve: These valves have two positions - open and closed - and are designed to transport liquid or gas flow. Available in a wide range of configurations with large port sizes, housing materials and degrees of protection.

- Norgren 3-position valve: These valves have three positions - open, closed and exhaust - and are used to pump a flow of liquid or gas in two directions.

- Norgren Proportional Valve: These valves provide stepless regulation of liquid or gas flow using a control signal.

Technical Specifications solenoid valves

Norgren solenoid valves are meticulously designed to deliver precision and reliability, establishing them as a fundamental component in industrial automation. With robust materials, adaptable pressure and temperature ranges, various electrical configurations, and strict adherence to compliance standards, these valves are equipped to meet the demands of diverse applications. Whether your industry is manufacturing, automotive, medical, or food and beverage, Norgren solenoid valves offer the dependable performance and efficiency required to enhance your automated systems.

General characteristics

- Type: Direct acting, pilot or proportional

- Actuator: Pneumatic diaphragm, pneumatic piston or pneumatic cylinder

- Functionality: 2/2, 3/2, 4/2 or 5/2-wave

- Medium: Air, vacuum, inert gases or liquids

- Material: Aluminum, stainless steel, brass or plastic

- Mounting: Wall, panel or recessed

- Connection: Threaded, fitting or flanged

- Voltage: 24 V DC, 120 V AC or 230 V AC

- Current consumption: Depending on the model

- Control type: DC, AC or pulse control

Specific characteristics

- Port size: G1/8, G1/4, G1/2, G3/4, G1, or others

- Maximum working pressure: From 0.5 bar to 350 bar, depending on the model

- Maximum operating temperature: From -20°C to +180°C, depending on the model

- Response time: From 2 ms to 50 ms, depending on the model

- Degree of protection: IP65 or higher

- Certification: CE, ATEX, UL, or others

These are just a few of the many types of Norgren solenoid valves.

Applications of Norgren Solenoid Valves

Norgren, a leader in industrial automation, offers a wide range of solenoid valves designed to meet the stringent demands of various industries.

Manufacturing Industry

- Assembly Lines: Solenoid valves are essential in manufacturing because they regulate the flow of fluids such as water, air, and other substances on automated assembly lines. Smooth and effective manufacturing processes are made possible by Norgren solenoid valves, which guarantee precise operation of robotic systems, conveyors, and pneumatic actuators.

- Machinery Control: Norgren solenoid valves are used in various machinery to regulate the operation of hydraulic and pneumatic systems. Their ability to provide accurate control of fluid flow enhances the performance and reliability of manufacturing equipment, from CNC machines to injection molding systems.

Automotive Industry

- Engine Management Systems: In the automotive sector, Norgren solenoid valves are vital for engine management. They control the flow of fuel, air, and exhaust gases, ensuring optimal engine performance and emissions control. These valves are crucial for systems such as fuel injection, turbocharging, and emission regulation.

- Vehicle Safety Systems: Norgren solenoid valves are also used in vehicle safety systems, including anti-lock braking systems (ABS) and airbag deployment. Their rapid response times and reliable operation are essential for ensuring the safety and reliability of these critical systems.

Medical Industry

- Medical Devices: In the medical field, precision and reliability are paramount. Norgren solenoid valves are used in various medical devices, including ventilators, anesthesia machines, and dialysis equipment. These valves provide accurate control of gases and fluids, ensuring the safety and effectiveness of medical treatments.

- Pharmaceutical Manufacturing: Norgren solenoid valves are essential to the production of pharmaceuticals. They ensure accurate pharmaceutical product dosing, mixing, and packing by managing the flow of liquids and gases in production processes. Their multi-media flexibility and sturdy build make them perfect for this heavily regulated sector.

Food and Beverage Industry

- Processing and Packaging: In the food and beverage industry, hygiene and efficiency are critical. Norgren solenoid valves are used in processing and packaging equipment to control the flow of ingredients, water, and cleaning agents. Their stainless steel construction and food-grade seals ensure compliance with hygiene standards and durability in challenging environments.

- Dispensing Systems: Norgren solenoid valves are also employed in dispensing systems for beverages and food products. Their precise control over fluid flow ensures consistent and accurate dispensing, enhancing product quality and customer satisfaction.

Energy Sector

- Oil and Gas: In the oil and gas industry, to regulate flow, Norgren solenoid valves are employed of hydrocarbons and other fluids in extraction, refining, and distribution processes. Their ability to withstand high pressures and corrosive environments makes them suitable for these demanding applications.

- Renewable Energy: Norgren solenoid valves are also utilized in renewable energy systems, such as wind and solar power generation. They control the flow of fluids in cooling, lubrication, and hydraulic systems, ensuring the efficient operation of renewable energy installations.

- Water and Wastewater Treatment: This systems require Norgren solenoid valves as important parts. In filtration, aeration, and chemical dosing, among other treatment procedures, they regulate the flow of water, chemicals, and air. The reliable and sturdy design of these essential systems guarantees their safe and effective operation.

Aerospace Industry

- Aircraft Systems: In the aerospace industry, Norgren solenoid valves are used in various aircraft systems, including fuel management, environmental control, and hydraulic systems. Their lightweight construction, reliability, and ability to operate under extreme conditions make them ideal for aerospace applications.

- Space Exploration: In order to regulate the flow of gases and fluids in spacecraft systems, Norgren solenoid valves are also utilized in space exploration. Their precision and reliability are essential for the success of space missions, where failure is not an option.

Advantages of using Norgren solenoid valves

Norgren solenoid valves are dependable and adaptable parts that are utilized in many different sectors and applications. Their popularity can be attributed to several important benefits.

1. Reliability

- Norgren solenoid valves are made using premium components and put through a thorough testing process to guarantee their longevity and wear resistance.

- Their ability to tolerate elevated pressures, temperatures, and vibrations makes them perfect for deployment in challenging settings.

- Due to their simple design and minimal moving parts, Norgren solenoid valves have a low probability of failure and require minimal maintenance.

2. Accuracy

- Norgren solenoid valves are perfect for use in systems that require very precise dosing or regulation because they offer precise control over liquid or gas flow.

- Fast response times allow them to respond quickly to control signals, ensuring accurate and timely execution of commands.

3. Speed

- Norgren solenoid valves have fast actuation times, making them ideal for use in systems where rapid flow changes are required.

- This makes them indispensable in dynamic systems where speed and accuracy are key factors.

4. Versatility

- Norgren solenoid valves can be used in a multitude of sectors and applications since they come in an extensive array of configurations.

- They are offered with different control types, port sizes, housing materials, and degrees of protection, allowing you to choose the best option for your specific needs.

5. Efficiency

- Norgren solenoid valves are energy efficient and resource saving.

- They consume a minimum amount of energy for operation, which makes them environmentally friendly and economically beneficial.

- Due to their reliability and minimal maintenance requirements, Norgren solenoid valves save time and money in operation.

6. Additional benefits

- Ease of installation: Time and resources are saved by the simplicity of the installation and removal of Norgren solenoid valves.

- Safety: They meet the strictest safety standards and are certified for use in various industries.

- Wide range of accessories: A wide range of accessories, such as mufflers, safety valves, and positioners, are available to extend the functionality of Norgren solenoid valves.

Using Norgren solenoid valves ensures reliability, accuracy, speed, versatility, economy, and safety in your system.

Conclusion

Norgren solenoid valves are fundamental to achieving high performance and reliability in industrial automation. Their robust construction, precise control, and adaptability to various conditions make them an ideal choice for a wide range of applications, including manufacturing, automotive, medical, food and beverage, energy, water treatment, and aerospace industries.

At Eltra Trade, we are proud to be norgren solenoid valve distributors, offering an extensive Catalog of norgren solenoid valves to meet a variety of industrial needs. Our experienced team is always on hand to assist with product selection and to answer any questions you may have. Whether you need expert advice on choosing the ideal valve for a specific application or require detailed technical support, we are here to help you find the perfect solution.