Rodless pneumatic cylinder working principle

01.02.2023

The most effective means of mechanization and automation of any production process is pneumatic equipment. It is used in metallurgical, metalworking, woodworking, packaging, textile, and other industries. The integral mechanisms of any pneumatic drive are pneumatic cylinders, which convert compressed air energy into mechanical work.

Today we will consider in detail what it is and how does a rodless cylinder work.

How Do Rodless Pneumatic Cylinders Work?

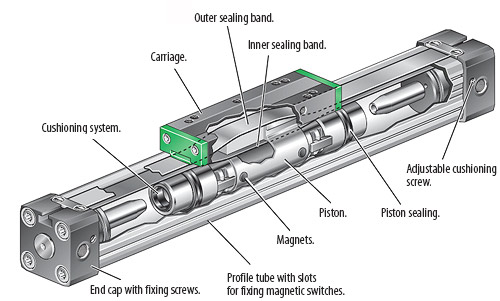

Let's see how do rodless cylinders work. Rodless cylinders are installed where conventional cylinders cannot be used (there is any space for the rod to extend). They are made in the form of anodized aluminum sleeves. The pneumatic cylinder has a longitudinal groove, which makes it possible to make a rigid connection between the piston and the movable carriage using a plate. A fixed steel band is pressed against the groove with the help of special magnets, which prevents leakage of compressed air and protects against dust ingress into the cylinder.

The cylinder is mounted either through special mounting holes on the covers or with the help of intermediate brackets. Rodless pneumatic cylinders are characterized by a high degree of reliability due to the fact that there are no external losses of compressed air. They withstand heavy loads and, unlike conventional cylinders, take up significantly less space during installation.

The rodless pneumatic cylinder is designed as a self-contained linear actuator with a unique design that provides great flexibility. With a unique design that uses only four main components, rodless cylinders are a durable, reliable solution that is easy to maintain for long, trouble-free operation. Rodless pneumatic cylinders combine controlled and precise movement with integral support and guidance in any plane:

- A flexible, hardened stainless steel inner strip running the full length of the groove and passing through the piston provides a metal seal. The outer strip of the same material acts as a cover over the groove, preventing foreign particles from entering the cylinder.

- The aluminum piston is equipped with synthetic bearing rings. The energy transfer is carried out by means of a connection through a groove to an external piston mount.

- Side covers provide air supply and cushioning.

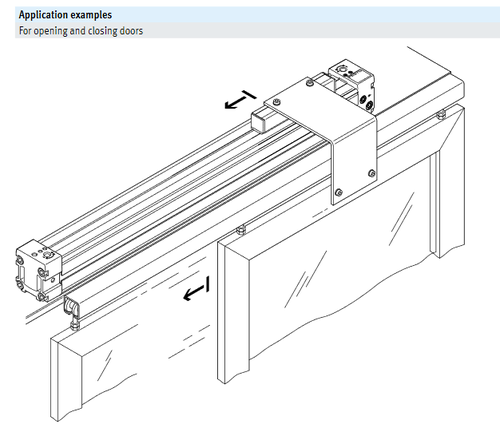

Rodless double-acting pneumatic cylinders are beneficial in applications where space is limited. This is due to the fact that the installation length of a rodless cylinder is slightly longer than the stroke of the cylinder. For example, a rodless cylinder with a diameter of 25 mm and a stroke of 1000 mm occupies only 1200 mm of space. When designing, a pneumatic rodless cylinder would be an ideal choice over a pneumatic rod cylinder for the following requirements:

- Requires a source of repetitive linear motion.

- Ensure cleanliness and minimize the risk of contamination from lubricants.

- Space saving is the main consideration, such as long-term use.

- Reliability and minimal maintenance of components is essential to protect against downtime.

- Overall length can present problems when designing or mounting cylinders on machines.

Typical applications:

- Automated production.

- Processing and packaging, e.g. bottling and canning.

- Textiles and ceramics.

- Warehousing.

- Pharmaceutics and chemistry.

- Food production.

- Inspection and quality control.

Specifying a rodless cylinder solution can provide significant engineering savings and greater design flexibility compared to using a cylindrical cylinder.

Rodless Cylinder Types

There are three main types of rodless cylinders, each of which is important, like using a piston holder to subsequently change the load.

- Magnetic pneumatic rodless cylinder. There is a magnetic connection between the piston and the holder. This results in a sealed cylinder. However, you may have to worry about disconnecting and rotating the load.

- Cable pneumatic rodless cylinder. A cable is connected to the piston and through a pulley at each end, then followed by a holder. This is a very simple design, however, due to the tension of the inflammatory process, outliers can occur.

- Slits pneumatic rodless cylinder. According to the content of the cylinder, there is a slot with an inner and outer metal strip to prevent leakage. This gives the carrier a direct mechanical connection with a piston. This allows them to be the most versatile and widespread.

Advantages and Disadvantages of a Rodless Cylinder

First, let's find out what are the advantages of rodless cylinders:

- The amount of effort does not change depending on the direction of movement.

- Direct connection to the piston, no rotation.

- 50% space saving.

- Various design options allow you to choose the optimal design for a specific task.

And now let's move on to the disadvantages of rodless pistons:

- Poor tightness, prone to emissions. When assembling a three-position valve, the medium pressure type must be selected.

- The load force is small. To increase the load capacity, you need to add a guide machine.

What is the Principle of the Pneumatic Cylinder?

Pneumatic cylinders are used for lifting devices and mechanisms, depreciation, and braking. Pneumatic cylinders according to the principle of operation are divided into single-sided and double-sided. They operate on compressed air pumped from special compressors, while pressure is formed in the working space of the cylinder. In one-sided pneumatic cylinders, compressed air exerts pressure in only one direction, and in the opposite direction the piston and rod return under the action of external forces (self-weight, spring return). In bilateral - the movement of the piston and rod in both directions occurs only under the action of compressed air.

The main advantages of pneumatic cylinders are easy maintenance, fire and explosion safety, and the ability to use in a wide temperature range, in humid and dusty environments. Pneumatic cylinders are low-cost (fast payback) and long life. Therefore, pneumatic cylinders can be considered one of the best options for achieving automation goals.

The force developed by the pneumatic cylinder is proportional to the pressure and the effective area. For this reason, when air is supplied to the piston cavity, the force on the pneumatic cylinder rod will be higher than when compressed air is supplied to the rod cavity. So, in order to calculate the pneumatic cylinder force, it is necessary to multiply the working air pressure by the piston diameter.

Eltra Trade offers a vast selection of rodless pneumatic cylinders from leading manufacturers. Our expert managers are always ready to assist with selection and answer any questions. We provide worldwide delivery and competitive pricing, ensuring our customers receive the best.