Siemens v70 Drive Fault codes

18.10.2024

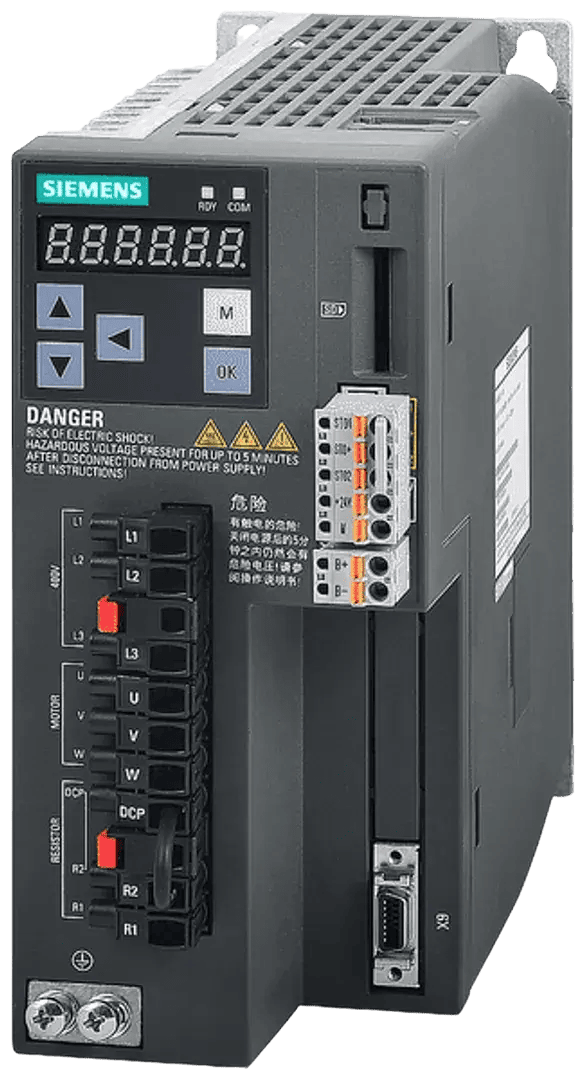

A highly specialized and adaptable option for effective motor control in industrial automation is the Siemens V70 drive. For businesses that need reliable and adaptable drive systems, it offers the ideal blend of performance, accuracy, and dependability. The V70 drive provides improved control for heavy-duty industrial and high-precision applications, enabling companies to save energy and run more efficiently.

Overview of V70 Drive

The Siemens V70 drive series is part of Siemens' renowned portfolio of automation solutions, offering advanced motor control for a wide range of applications. These drives are engineered with state-of-the-art vector control technology, allowing precise regulation of motor speed and torque. This means that the V70 series can adapt to changing load conditions, providing optimal performance at all times. Its compact design makes it ideal for space-constrained installations, while its scalability allows integration into both small- and large-scale automation systems.

One important element of the V70 drive is its integrated diagnostics, which provide real-time motor performance and system health monitoring. By detecting problems early, this self-diagnostic feature lowers maintenance expenses and downtime. The drive also supports a wide range of communication protocols, which guarantees a smooth interaction with current automation networks. The Siemens V70 drive series' high degree of configurability makes it appropriate for a variety of applications, from packaging systems and conveyors to more sophisticated equipment in sectors including material handling, food processing, and automotive.

Importance Siemens v70 in Industrial Automation

In the realm of industrial automation, motor control is critical to the efficiency and performance of production processes. The Siemens V70 drives offer precision control over motor functions, ensuring that equipment operates at peak efficiency. This is particularly important in environments where consistency, accuracy, and reliability are non-negotiable.

The V70 series drives help optimize energy use, reducing power consumption even under heavy load conditions. This contributes to lower operational costs and supports sustainability initiatives by reducing the overall energy footprint of industrial operations. Furthermore, by delivering real-time adjustments to motor performance, the Siemens V70 drive ensures smooth transitions, minimizing wear and tear on mechanical components and extending the life of both the drive and the motor.

For industries that depend on high-output, continuous operation, such as automotive manufacturing, pharmaceuticals, and food and beverage processing, the Siemens V70 drive plays a pivotal role in maintaining productivity while ensuring that production lines run without interruptions. Its ability to integrate with complex automation systems ensures that every aspect of motor control is optimized, making it a key enabler of modern industrial efficiency.

Fault Codes in Siemens V70 Drives

When working with high-performance drives like the Siemens V70 in industrial settings, fault codes are unavoidable. These fault codes are intended to identify certain problems, facilitating effective troubleshooting and reducing downtime. A comprehensive list of frequently occurring Siemens V70 drive fault codes, along with suggestions for fixing them and their causes, may be found below.

| Fault Code | Description | Why It Occurs | How to Fix It |

| F001 | Overvoltage | The supply voltage exceeds the drive’s maximum rated voltage. | Inspect the power supply for surges or fluctuations. Install surge protection devices if necessary. |

| F002 | Undervoltage | Voltage supplied to the drive is below the required minimum level. | Check the input power for inconsistencies or interruptions. Ensure proper voltage levels and stable power. |

| F003 | Motor Overload | The motor is drawing excessive current, leading to overheating. | Evaluate the load on the motor and adjust if it's too high. If persistent, resize the motor or check for mechanical issues causing overloading. |

| F004 | Ground Fault | A short circuit between a phase and the ground occurs. | Inspect wiring for insulation breakdown or damage. Repair or replace faulty cables and check for proper grounding. |

| F005 | Overcurrent | The drive is experiencing a current spike, often due to a short circuit. | Investigate for short circuits in motor windings or wiring. Address any motor or drive hardware failures. |

| F006 | Drive Overtemperature | The drive’s internal temperature exceeds safe operating limits. | Check for proper ventilation and cooling fan operation. Clean dust and debris from cooling systems and ensure ambient temperatures are within the drive's specifications. |

| F007 | Motor Overtemperature | Motor temperature has surpassed its operational threshold. | Ensure proper motor cooling mechanisms are functioning. Reduce motor load and allow cooling periods as necessary. |

| F008 | Phase Loss | One or more of the three input phases is missing or faulty. | Verify the power supply and wiring connections. Ensure all three phases are properly connected and functioning. |

| F009 | Communication Error | Failure in the communication between the drive and external systems. | Check communication protocols, cables, and settings. Reconfigure or repair communication lines as needed. |

| F010 | Motor Stall | The motor has stopped or stalled due to excessive load or jamming. | Inspect for mechanical blockages or jams. Reduce motor load, and reset the drive once the issue is resolved. |

| F011 | Encoder Fault | The feedback signal from the encoder is incorrect or absent. | Check encoder connections and calibration. Replace the encoder or correct any wiring faults. |

| F012 | DC Bus Overvoltage | The DC bus voltage is too high, often due to regenerative energy. | Install braking resistors or check for regenerative feedback issues. Ensure the system is not feeding excess energy back into the drive. |

| F013 | DC Bus Undervoltage | The DC bus voltage is below the minimum required level. | Check the power supply and ensure voltage stability. Repair or replace faulty components in the power circuit. |

| F014 | External Fault | An external device connected to the drive has signaled a fault. | Identify the external fault source by reviewing connected equipment. Address issues in the external devices or signals. |

| F015 | Brake Control Fault | Malfunction detected in the drive’s braking system. | Inspect the brake resistor, wiring, and control circuits. Repair or replace damaged braking components. |

| F016 | Short Circuit | A direct short has occurred in the motor or output wiring. | Inspect the motor windings and drive output cables for short circuits. Replace damaged wiring or motor components. |

| F017 | Power Supply Failure | The drive is receiving insufficient or fluctuating power. | Verify the power source for stability. Check and repair any damaged power supply cables. Replace faulty power components if necessary. |

| F018 | Fan Failure | The cooling fan of the drive is malfunctioning. | Check for blockages or dust accumulation in the fan. Replace the cooling fan if necessary to maintain drive temperature. |

| F019 | Control Board Failure | The internal control board has malfunctioned. | Power cycle the drive. If the fault persists, replace the control board or the drive. |

By understanding these fault codes and taking prompt corrective action, you can ensure smoother operation of your Siemens V70 drive and avoid prolonged disruptions in your industrial processes.

How to Diagnose Siemens V70 Drive Faults

In order to guarantee seamless operation and save downtime in industrial systems, diagnosing problems with a Siemens V70 drive is an essential procedure. Detailed instructions for diagnosing Siemens V70 drive issues.

1. Read the Displayed Fault Code

The first step in diagnosing a Siemens V70 drive is to read the fault code displayed on the drive’s interface. Fault codes provide the initial clues about the nature of the issue, whether it's related to power supply, communication, or motor overload. Each code corresponds to a specific problem, allowing for targeted troubleshooting. The V70 drive features a digital display that immediately shows an error code when a fault occurs.

2. Inspect Power Supply and Connections

Many common faults, such as overvoltage (F001) or undervoltage (F002), are related to issues with the power supply. Inspect the power source to ensure it’s stable and within the drive’s specified voltage range.

Action: Use a multimeter to check the input voltage. Verify that all three input phases are present (for three-phase systems) and that connections are secure. Loose connections can also cause phase loss or erratic drive behavior.

3. Monitor Motor Load and Performance

If the fault code is related to motor issues, such as overcurrent (F005) or motor overload (F003), the next step is to evaluate the motor’s condition and load. Excessive load, mechanical binding, or motor misalignment can lead to these faults.

Action: Check the mechanical load connected to the motor. Ensure the motor is operating within its rated limits, and inspect for any mechanical blockages or binding in the equipment. Reduce the load if necessary and observe motor performance under normal operating conditions.

4. Check Drive Temperature and Ventilation

Overtemperature faults (F006 and F007) are common in drives operating in harsh or poorly ventilated environments. The drive or motor can overheat due to dust buildup, inadequate cooling, or ambient temperature exceeding the drive’s rated limits.

Action: Inspect the drive’s cooling system, including fans and heat sinks, for dust or obstruction. Ensure that the drive is installed in a well-ventilated area, and if needed, clean or replace cooling components. Reducing the ambient temperature or adding additional cooling fans may also help prevent future overheating issues.

5. Verify Communication Systems

Fault codes related to communication errors (F009) occur when the drive is unable to communicate with external control systems. This is often due to wiring issues, misconfigured communication settings, or faulty communication modules.

Action: Check all communication cables for proper connections. Ensure that the communication protocols, such as Modbus or Profibus, are correctly configured in both the drive and the control system. If necessary, replace damaged cables or communication modules.

6. Examine External Devices

In cases where an external fault (F014) is signaled, the issue may lie in connected devices or peripherals. External faults can be triggered by sensors, relays, or other equipment tied to the drive’s control system.

Action: Inspect any external devices connected to the drive, ensuring that they are functioning properly. Test each device individually to isolate the fault source. Once identified, repair or replace the faulty device.

7. Perform a Reset and Test Run

Once the potential issues have been addressed, perform a reset of the sinamics v70 to clear the fault. After resetting, run the system under normal operating conditions to verify that the fault does not reoccur.

Action: Use the drive’s reset function to clear the fault code. Conduct a test run to monitor performance and ensure that the system is operating within its specified parameters. If the fault reappears, revisit the diagnostic steps or consult with a Siemens technical specialist for further assistance.

8. Utilize Drive Monitoring and Diagnostic Tools

For ongoing fault diagnosis and prevention, many Siemens V70 drives are equipped with advanced monitoring and diagnostic features. These tools allow for real-time tracking of drive performance and can provide early warnings of potential issues before they result in faults.

Action: Enable the drive’s built-in monitoring systems, and set up alerts for critical parameters such as voltage, current, and temperature. This proactive approach allows for early intervention and reduces the likelihood of unexpected faults.

By following these steps, you can effectively diagnose and resolve issues with Siemens V70 drives, ensuring optimal performance and minimizing downtime. Regular maintenance, combined with the use of built-in diagnostics, can help prevent recurring faults and prolong the lifespan of the drive.

Preventive Measures to Avoid Siemens V70 Drive Fault Codes

To maintain the optimal performance of Siemens V70 drives and prevent fault codes from occurring, implementing proactive maintenance and preventive measures is essential. This not only extends the lifespan of the drive but also ensures reliable operation in industrial automation systems. Below are some key preventive strategies and answers to frequently asked questions regarding the maintenance of Siemens V70 drives.

1. Regular Maintenance and Inspections

Routine maintenance is crucial to identify potential issues before they escalate into faults. Schedule regular inspections of the drive and connected components to ensure everything is functioning as intended.

2. Monitor Operating Conditions

Keeping an eye on the operating environment can help prevent faults caused by excessive temperatures, humidity, or dust accumulation.

3. Proper Wiring and Power Supply Checks

Faulty wiring or an unstable power supply can lead to various fault codes, including phase loss and overvoltage.

4. Load Management

Understanding the operational limits of the motor and drive helps to avoid overload conditions that can trigger fault codes.

5. Training and Awareness

Educating personnel about the Siemens V70 drive, its operation, and potential issues can significantly enhance troubleshooting efforts.

Conclusion

Understanding and addressing Siemens V70 drive fault codes is crucial for maintaining efficient and reliable industrial automation processes. By familiarizing yourself with the common fault codes, their potential causes, and appropriate troubleshooting steps, you can significantly reduce downtime and improve overall system performance.

If you're looking for a reliable source for Siemens and expert assistance, Eltra Trade offers a comprehensive selection of Siemens drive . Our experienced specialists can guide you through the selection process, answer technical questions, and provide valuable insights into troubleshooting and maintenance. With our worldwide shipping capabilities, we can deliver your Siemens drives to your location, wherever you may be.

Don't let drive faults disrupt your operations. Contact Eltra Trade today to learn more about our offerings and how we can help you optimize your industrial automation systems.