The main types of pneumatic cylinders

08.09.2022

Pneumatic cylinders are actuators of pneumatic systems and are designed to convert the energy of compressed air into mechanical linear movement.

Today we will talk about what a pneumatic component sda compact cylinder is, as well as their design and principle of operation.

What is a Pneumatic Compact Cylinder?

Today, compact pneumatic cylinders using compressed air are most often the go-to solution when space is limited and mechanical actuation is required. A typical compact air cylinder falls between the bore size range of ½ to 4 inches (12 to 125 mm) with standard strokes of 1/16 to 4 inches (1.5 to 125 mm). With a typical maximum standard of 4-in. (125 mm), these cylinders are also often referred to as short stroke cylinders.

Compact pneumatic cylinders have a piston rod configuration (as opposed to a brushless cylinder). Piston rod cylinders work in two ways: double and single-sided. Double-acting cylinders use compressed air to power both the retract stroke and the retract stroke (moving the rod back and forth). This design makes the double-acting cylinders ideal for pushing and pulling loads.

Single-acting cylinders have compressed air supplied to only one side of the piston; the other side is receding from the atmosphere. Depending on whether air is directed to the cap or the end of the rod, whether the elongation or retraction of the rod is determined. The most common type is pressurized expansion with an internal spring that returns the piston to its original position when air is expelled. This is commonly referred to as spring return.

The spring expands when air pressure retracts the rod, and the spring force causes the rod to expand when the pressure is removed. This makes single-acting cylinders suitable for applications where force is needed in only one direction and where the return stroke is unobstructed and unloaded. They are also popular in areas where, for safety reasons, a certain position must be taken in the event of a power failure.

What is a Compact Cylinder?

Compact double-acting short-stroke cylinder. Used for low travel clamping operations on a variety of devices that require a fast response to air supply, and high clamping force in a minimum installation space.

Compact, short-stroke cylinders have been specially developed for applications where space is limited, as well as for those applications in which the axial dimension is the most important, with low side loads with small stroke and travel speed.

Compact cylinder pneumatic has a similar design with profiled pneumatic cylinders. The difference lies in the narrower covers and piston, as well as the presence of a shortened support sleeve. The product diameter range is 12-125 mm, with a stroke length of 25 mm for single-acting models and up to 500 mm for double-acting models.

With certain restrictions on speed and side load, however, compact cylinders proved so popular that the ISO 21287 standard was developed for them. manufactured in accordance with ISO 15552.

For compact pneumatic cylinders, it becomes possible to use various additional options, including a special temperature version, clamps, and a magnetic ring for sensors.

What are the Different Types of Pneumatic Cylinders?

There are two types of pneumatic cylinder:

- Piston pneumatic cylinders are designed to convert the energy of compressed air into reciprocating motion of the rod. When compressed air is supplied to one of the cavities of the cylinder and the other cavity is connected to the atmosphere, the piston moves along with the rod, creating a pushing or pulling force.

- Diaphragm pneumatic cylinders are used for regulating types of pipeline fittings.

Pneumatic cylinders are divided into single-acting and double-acting cylinders, with a single-sided or double-sided (through) rod, they are piston and diaphragm.

In single-acting pneumatic cylinders, the piston can move under the action of compressed air only in one direction (air is supplied only from one side of the piston), and the piston is returned due to the action of a return spring or external forces. In this case, the air supplied to the pneumatic cylinder must be discharged into the atmosphere. In such cylinders, the return spring reduces the forward stroke force developed by the cylinder under the action of compressed air, and the force when returning to its original position is determined by the stiffness and degree of compression of the spring. The return stroke of such pneumatic cylinders is usually not used as a working one.

In double-acting pneumatic cylinders, the movement of the rod occurs under the action of compressed air in the forward and reverse directions. For such pneumatic cylinders, both forward and reverse strokes are working. However, the force developed by the double-acting pneumatic cylinder during the reverse stroke is lower than the force developed by the cylinder during the forward stroke.

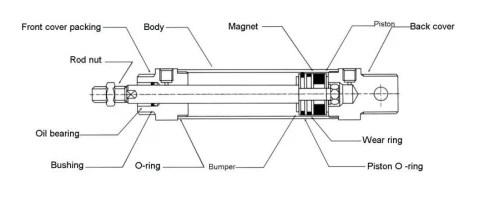

If it is necessary to control the movement of the piston rod, a magnetic ring is installed on the piston. A reed sensor is mounted on the body of the pneumatic cylinder. When the sensor is triggered, the LED on it lights up.

What are Pneumatic Cylinders Made Of?

The main and most commonly used pneumatic motor is the pneumatic cylinder, and this explains the wide variety of its designs. The pneumatic cylinder of standard design contains a body consisting of a sleeve, a front cover, a rear cover and four tie rods tightened with nuts. Piston and rod fastened with a nut and washer (piston and rod can be made in one piece in small size pneumatic cylinders). Guide sleeve pressed into the front cover for stem locating. A set of seals for movable joints and for fixed ones, as well as a wiper installed in a cover, fixed on the front cover.

How do Pneumatic Cylinders Work?

Compressed air from a compressor or other source is supplied to the piston cavity of the pneumatic cylinder, the rod cavity at this moment is connected to the atmosphere with the help of a distributor, and the pressure of compressed air acts on the piston, causing it to move until it rests against the front cover. The pneumatic cylinder makes a straight stroke, and its rod extends.

To carry out the reverse stroke, it is necessary to supply compressed air to the rod end, and the piston end to be connected to the atmosphere. Under the action of compressed air pressure, the piston will move, and the rod will move.

The direction of compressed air flows into the piston and rod cavities, as well as their connection with the atmosphere or the discharge line, is carried out using special devices - pneumatic distributors.

Eltra Trade offers a wide selection of pneumatic cylinders from leading manufacturers like Univer, SMC, Norgren, and Bosch Rexroth. We provide worldwide delivery and competitive pricing, ensuring the best value for our customers.