Understanding Festo Pneumatic Valves: Selection Guide for Industrial Use

30.06.2025

In modern industrial systems, where automation and precise process control play a decisive role, the correct choice of pneumatic valves becomes one of the foundations of reliable and efficient operation of the equipment. The speed and accuracy of the system, as well as its durability, safety and productivity, depend on the quality and characteristics of the valve you choose. That is why it is so important to have a detailed and understandable valve selection guide, which will allow you to select the optimal valve for specific operating conditions.

Festo has earned recognition worldwide as a manufacturer of high-quality and innovative automation solutions. Their range includes various models and configurations of valves that are adapted to a wide range of tasks in industrial automation. In this material, we will consider in detail the main types of Festo valves, their structure, operating principle and features of selection for industrial use. You will learn how to properly optimize the operation of a pneumatic system, based on technical characteristics and expert recommendations.

CONTENT:

- What Are Pneumatic Valves and How Do They Work?

- Overview of Common Festo Pneumatic Valve Types

- Key Factors When Selecting a Festo Pneumatic Valve

- Pros and Cons of Festo Pneumatic Valves

- Typical Applications in Industrial Automation

- How to Match the Valve to Your Application

- Conclusion

What Are Pneumatic Valves and How Do They Work?

Pneumatic valves are the main elements in compressed air systems that are responsible for controlling the airflow inside the pneumatic network. Their main task is to control the direction, quantity ,and pressure of air, which ensures the operation of various actuators, such as pneumatic cylinders and actuators.

The operation of a pneumatic valve is based on the principle of controlling the airflow by changing the airflow paths inside the device. The main components of the valve include a housing that contains ports for the air inlet and outlet, an actuator, and a control system, which can be electric (solenoid), pneumatic, or mechanical (manual control). The control signal starts the actuator, which opens or closes the channels for air passage.

Thus, compressed air valve operation is a complex process of coordinating the action of various components that will provide the desired direction and pressure of the flow in the system. The stability and safety of your entire system depend on the correct choice of valve design and its parameters.

Overview of Common Festo Pneumatic Valve Types

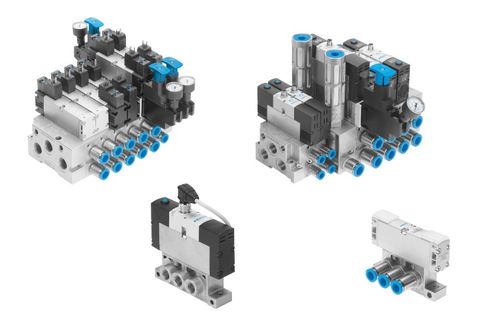

Festo offers a wide range of pneumatic valve types, each designed to meet specific industrial automation requirements. Let's look at the main valve groups to understand their purpose and capabilities.

Directional Control Valves

Directional control valves are responsible for the direction of compressed air flow and act as switches that determine where and how the flow will be directed in the pneumatic system. The most common configurations are:

- 2/2 valve – two ports, two positions (open/closed), the simplest form of valve for turning the air supply on or off;

- 3/2 valve – three ports and two positions, often used to relieve pressure or switch between operating states;

- 5/2 valve – five ports and two positions, used to control two-way pneumatic cylinders;

- 5/3 valve – five ports and three positions, including a neutral position for blocking or relieving pressure.

Festo manufactures these valves in several drive variants, if you will choose between solenoid vs manual pneumatic valves, as well as with pneumatic pilot control. Here's a quick explanation. Electric valves with solenoids provide fast and precise operation with the possibility of remote control. Manual valves are more often used for local control and system adjustment. Pneumatic pilot valves are convenient in complex systems with a high frequency of operations and the need to minimize energy costs.

Flow Control Valves

Flow control valves are an important tool for fine-tuning the speed of actuators. Such valves allow you to change the volume of air passing per unit of time, which directly affects the speed of cylinders and other devices.

Main types:

- One-way flow control valves, which allow you to limit or increase the airflow in one direction;

- Two-way valves, are able to regulate the flow in both directions, which is important for systems with feedback and precise cycle control.

Flow control valves for machines from Festo are characterized by high adjustment accuracy and stability of characteristics over a wide range of operating conditions. Their use helps to significantly increase overall productivity and reduce component wear.

Pressure Control Valves

In compressed air systems, it is extremely important to maintain pressure within specified limits to prevent breakdowns and ensure optimal operation of the equipment. For this purpose, pneumatic control valves are used that regulate and stabilize pressure.

Main types:

- Pressure relief valves that automatically release excess pressure;

- Pressure-reducing valves that reduce pressure to a safe level;

- Combination valves that perform several functions simultaneously.

These devices prevent damage and reduce the risk of emergencies, which is critical for industrial safety and uninterrupted operation.

Key Factors When Selecting a Festo Pneumatic Valve

To select the optimal valve from the Festo range, it is necessary to take into account several important parameters. The following Festo valve selection guide will help you correctly evaluate the main characteristics and select a device that fully meets the requirements of your system:

- Port size and flow rate (Cv value): affects the air flow rate and overall system performance. The higher the Cv, the higher the flow;

- Drive type: valves are available with manual, electric (solenoid), or pneumatic control. The choice depends on the requirements for switching speed, cycle frequency, and type of system control;

- Pressure and temperature range: valves must withstand operating conditions without reducing performance;

- Control system compatibility: electromechanical parameters, communication protocols, voltage, and signal type;

- Environmental conditions: degree of protection (IP rating), resistance to dust, moisture, and aggressive environments.

Taking these factors into account, you can significantly increase the efficiency and reliability of the entire pneumatic installation and achieve pneumatic system optimization.

Pros and Cons of Festo Pneumatic Valves

When choosing valves, you need to pay attention to the technical characteristics of Festo pneumatic valves, and understand their advantages and limitations.

Advantages

Below you can see the qualities that make Festo automation components the best among competitors:

- High reliability and long service life, which reduces maintenance and replacement costs;

- Modular design, which allows flexible system configuration and easy integration of additional components;

- Fast response and stable operation even at high cycle rates;

- A wide range of control options: manual, electric and pneumatic, which allows you to select a device for any requirement.

Considerations

Understanding these aspects will help you avoid design and operation errors:

- Not suitable for working with liquids and high-pressure systems;

- For optimal operation, a supply of clean, dry air is required, which places demands on the quality of air preparation;

- The valve size and parameters must be carefully selected taking into account all operating conditions, otherwise malfunctions are possible.

Typical Applications in Industrial Automation

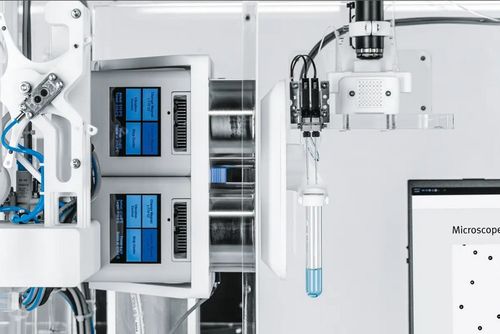

Industrial pneumatic valves from Festo are widely used in various areas of industrial automation. Their versatility and reliability make them indispensable components for solving many problems. Below, we will check Festo valve applications.

The main industrial valve applications include:

- Robotics for pick-and-place operations, where precise and fast control of manipulator movements is required;

- Conveyor control systems, where valves regulate air flows to move and stop products;

- Packaging machines that ensure high speed and quality of product packaging;

- Technological processes in the food and beverage industry, where hygiene and safety are important;

- Control of pneumatic cylinders and actuators in various industrial automation systems.

For complex solutions, experts recommend using the valves together with other Festo products, such as Festo rotary actuators and Festo classic cylinders.

How to Match the Valve to Your Application

“How to choose pneumatic valves?” – you may ask. Your valve selection starts with a clear understanding of your machine requirements and operating conditions. This section provides specific recommendations based on practical experience and technical data.

Answer the questions:

- What is the response speed and cycle rate?

- What load and pressure must the valve withstand?

- What conditions will it operate in (temperature, dust, humidity)?

- What are the requirements for the control interface?

Use Festo technical handbooks, catalogs, and online configurators to find the best product for your application. In complex cases, we recommend that you consult with experts. This approach is in line with the principles of the valve selection guide, allowing you to get the most out of your equipment.

Conclusion

Selecting the right pneumatic valve is an important step toward creating a reliable and efficient automation system. Knowing the types of Festo pneumatic valves, their features and operating conditions will help you avoid mistakes and ensure long-term stable operation of the equipment.

If you want to get additional information, we recommend that you carefully study the technical specifications and use the pneumatic valve guide from specialists. Also, using only original Festo components guarantees high quality and compatibility.

Need help selecting the right Festo pneumatic valve? Contact ELTRA TRADE for expert support and a full catalog of original Festo components.