Festo Valves

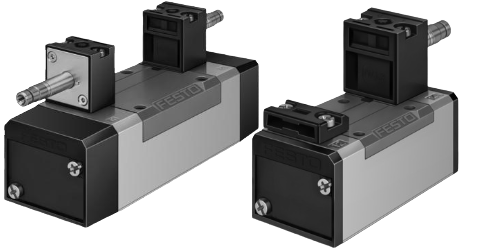

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 1400 l/min |

| Pneumatic connection, port 1 | G1/4 |

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 350 l/min |

| Pneumatic connection, port 1 | M7 |

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 350 l/min |

| Pneumatic connection, port 1 | M7 |

| Valve function | 2x3/2-way, monostable, closed |

| Standard nominal flow rate (standardised to DIN 1343) | 400 l/min |

| Pneumatic connection, port 1 | Common line |

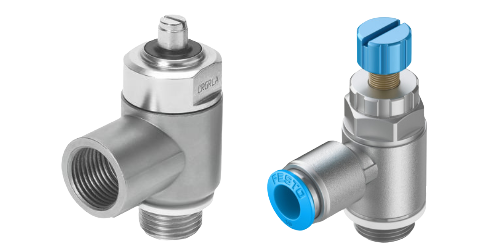

Festo GRLA

| Valve function | One-way flow control function |

| Standard nominal flow rate in flow control direction | 340 l/min |

| Pneumatic connection, port 1 | G1/8 |

Festo GRLA

| Valve function | Exhaust air one-way flow control function |

| Standard nominal flow rate in flow control direction | 1580 l/min |

| Pneumatic connection, port 1 | QS-12 |

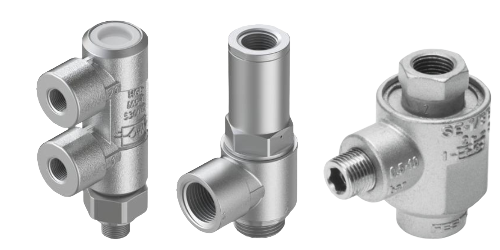

Festo HGL

| Valve function | Piloted non-return function |

| Pneumatic connection, port 1 | G1/2 |

| Pneumatic connection, port 2 | G1/2 |

| Operating pressure | 0.5 bar - 10 bar |

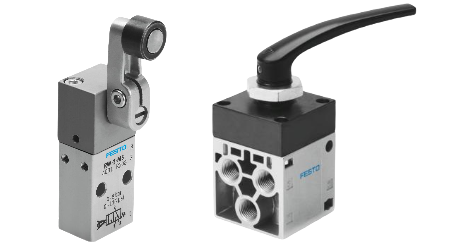

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 1200 l/min |

| Pneumatic connection, port 1 | Sub-base size 1 to ISO 5599-1 |

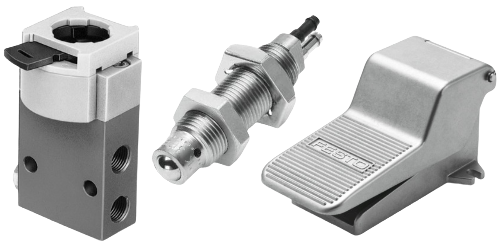

Festo MH2

| Valve function | 5/2-way, monostable |

| Standard nominal flow rate (standardised to DIN 1343) | 90 l/min |

| Pneumatic connection, port 1 | QS-4 |

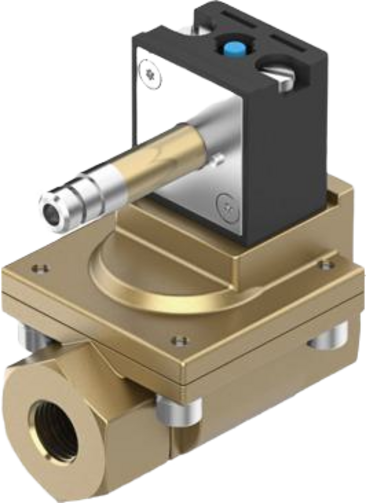

| Design | Diaphragm valve |

| Valve function | 2/2-way, closed, monostable |

| Connection Process valve | G1/2 |

| Standard nominal flow rate (standardised to DIN 1343) | 3100 l/min |

Festo MSFG

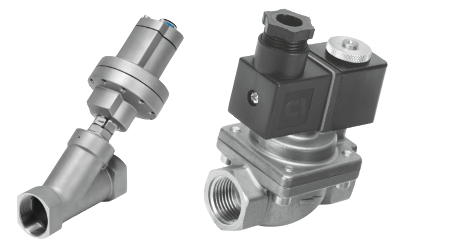

Festo VPCF

| Valve function | 3-way proportional flow control valve |

| Pneumatic connection, port 1 | G3/8 |

| Flow rate control range | 30 l/min - 1500 l/min |

| Signal range analogue input | 4 - 20 mA |

Festo VPPM

| Valve function | 3-way proportional pressure regulator |

| Pneumatic connection, port 1 | G1/2 |

| Pressure regulation range | 0.06 bar - 6 bar |

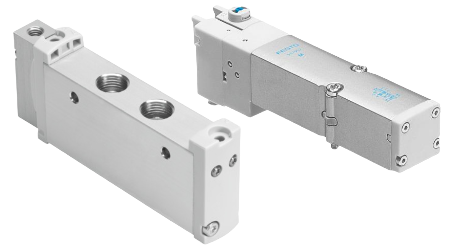

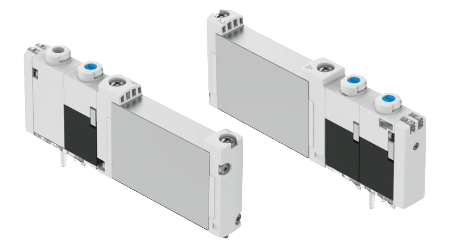

Festo VUVG

| Valve function | 5/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 200 l/min - 300 l/min |

| pneumatic working port | Flange |

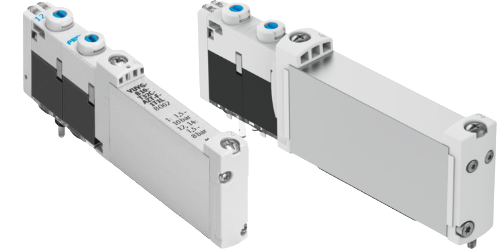

Festo VUVS

| Valve function | 5/2 double solenoid |

| Standard nominal flow rate (standardised to DIN 1343) | 700 l/min |

| Pneumatic connection, port 1 | G1/8 |

Festo VUVS

| Valve function | 5/3 closed |

| Standard nominal flow rate (standardised to DIN 1343) | 700 l/min |

| Pneumatic connection, port 1 | G1/8 |

173943, 2x3/2 closed, 550 l/min, Electric

When it comes to efficiently managing the pneumatic systems in your manufacturing plant, valves are one of the most essential components. They regulate air flows, ensure safety, increase productivity, and reduce maintenance costs. Festo valves are a guarantee of reliability and precision, making them indispensable components in automation and pneumatic systems. Festo offers a wide range of valves designed to operate in a wide range of industrial environments, from small production facilities to large factories.

Festo valves are designed to control air and other working media flows in pneumatic systems. They provide precise regulation of air flows, which helps to increase the productivity, safety, and energy efficiency of your equipment. Festo products are known for their high quality, reliability, and innovative solutions, making them a market leader in pneumatic and automation solutions.

Now let's take a closer look at why Festo pneumatic valves are a great choice for your company and how they can improve the operation of your systems.

Why Choose Festo Valves?

Festo valves are the solution for those who value quality, reliability, and high technological standards. By choosing products from this company, you get advanced pneumatic technologies that help increase the efficiency of your production.

Festo offers a wide range of valves, each of which is designed to perform specific tasks. From simple flow control to precise regulation and system protection - you will always find a solution that best suits the needs of your production. Festo solenoid valves provide precise and fast control, which is especially important for automated systems, where response speed is critical.

Indeed, Festo products always meet the highest quality standards. This ensures that even under the most difficult operating conditions, the valves will work stably and efficiently, which reduces the risk of accidents and equipment downtime. The reliability of the valves is confirmed by numerous international certificates, which makes them an ideal choice for industry.

In addition, Festo valves are designed taking into account modern trends in energy efficiency and ecology. Reducing energy losses and optimizing processes are important tasks for modern production systems, and these valves fully meet these requirements.

Explore Our Range of Festo Valves

Festo offers a wide range of valves, each designed to meet the specific requirements of different industries. If you want reliable solutions for controlling air flow and increasing the efficiency of your production, Festo valves are the perfect choice. In the Festo valves catalogue you will find valves for every need, from simple solutions to high-tech systems.

One of the popular categories is pneumatic valves. They provide reliable control of pneumatic systems, allowing you to precisely control your production processes. For example, Festo air valves are used to control air flows in automation systems, ensuring their stable operation even under heavy loads.

The company also offers solutions for specific tasks, such as Festo process valves, which are used to control the flow of liquids and gases in industrial processes. These valves are ideal for complex production systems that require precise and reliable process control. If your production requires more complex process automation solutions, you should pay attention to Proportional valves technology, which offers you a high level of control.

No matter what your valve needs are, Festo offers solutions that meet the highest requirements. By choosing Festo valves, you get products that will ensure the reliable operation of your production for many years.

Benefits of Using Festo Valves

Festo valves provide you with many benefits that help make your production processes more efficient and cost-effective. Below we will look at the main advantages of using valves from this company.

High quality and reliability

Festo valves are manufactured using modern technologies and high-quality materials. This guarantees their durability and resistance to loads, which is especially important for work under high pressure or high temperatures. You can be sure that these valves will serve you for a long time, ensuring the smooth operation of your equipment.

Precise control and accuracy

Thanks to their well-thought-out design, Festo valves provide precise control of air or liquid flows. This is especially important for automated systems that require high response accuracy. Solenoid valves for automation from Festo allow you to control every aspect of your equipment, ensuring the stability and accuracy of processes.

Energy efficiency

Festo valves are designed in such a way as to minimize energy losses. This allows for a significant reduction in resource consumption, which is especially important for companies seeking to reduce energy costs and increase production profitability. The technologies that Festo uses in its valves contribute to precise flow control, which will help you optimize energy consumption.

Long service life

Thanks to the use of high-quality materials and advanced technologies, Festo valves have a long service life. This reduces the need for frequent replacement or repair, which helps save time and money on equipment maintenance. These valves maintain their efficiency even during long-term operation in difficult conditions.

Easy installation and maintenance

One of the important advantages of Festo valves is their ease of installation and maintenance. Even complex models are easily integrated into existing systems and do not require specialized equipment for installation. This allows you to save time and resources on setting up the system and its subsequent maintenance.

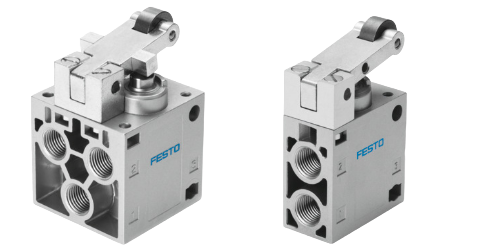

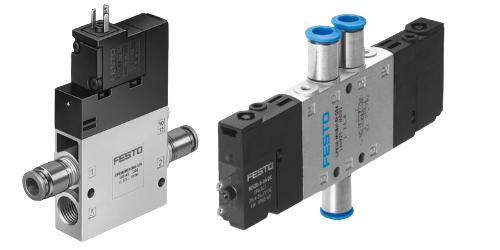

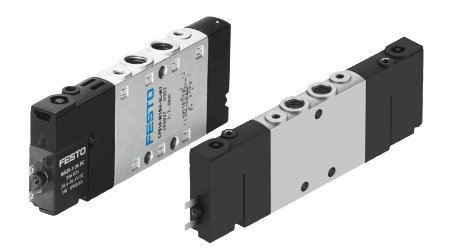

Types of Festo Valves

Festo offers a wide range of valves, each designed to perform specific tasks in pneumatic systems. Let's look at the main types of valves offered by Festo.

- Solenoid valves

These valves are a solution for fast and precise control of air or liquid flows in automated systems. They are characterized by high reaction speed, which makes them indispensable in production processes that require prompt switching of flows.

- Safety valves

Such devices protect equipment from exceeding the permissible pressure. They automatically release excess pressure, preventing breakdowns and emergencies, which guarantees the safety of your production.

- Check valves

This equipment prevents backflow of the working medium, ensuring stable operation of the system. This is especially important in cases where back pressure can damage equipment or cause malfunctions in the entire system.

- Flow control valves

These valves allow you to precisely regulate the amount of working medium, which helps optimize the operation of the equipment. They are ideal for systems that require constant control of air or fluid flow.

- Directional control valves

These devices provide precise flow direction control in pneumatic systems. They are used in complex automated processes that require fast and precise distribution of air or other working fluid flows.

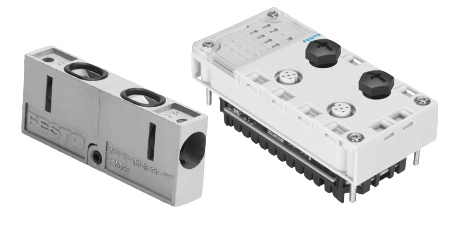

Festo Valves: Precise Monitoring for Your Industrial Processes

Festo pneumatic actuator valves not only provide reliable flow control but also allow you to precisely control and monitor processes. The introduction of modern technologies in Festo valves makes it possible to integrate them into automated monitoring systems, which allows you to monitor every stage of the pneumatic system in real time.

Monitoring air flows, pressures, and other parameters is an important aspect of preventing accidents and optimizing production processes. Festo valves are compatible with modern control and monitoring systems, which makes them ideal for use in complex automated systems. You can be sure that each valve will operate stably and accurately, giving you complete control over production.

Using industrial flow control valves from Festo allows you to not only regulate flows but also improve the safety and efficiency of your production processes. This makes Festo valves the ideal choice for any modern enterprise.

Why Choose Festo Valves?

Festo offers innovative solutions for pneumatic control systems that are highly precise and reliable. Regardless of your production type, these devices will help you optimize your work and increase productivity.

Festo valves provide precise control over air flows, allowing you to improve the stability of your equipment. In addition, they are easy to integrate into existing automation systems and require minimal maintenance, making them the perfect choice for your production.

Finally, Festo offers a wide range of valves, allowing you to choose the solution that is perfect for your needs. Choose Festo valves to optimize your production processes and increase the efficiency of your business.