What is electromagnetic flow meter?

29.07.2019

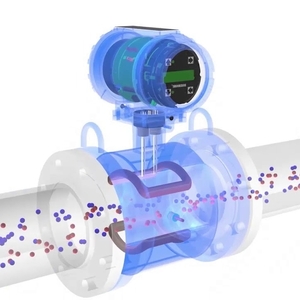

Electromagnetic (induction) flow meters measure the consumption of a substance in a pipeline using magnetic fields.

CONTENTS:

Magnetic flow meter working principle and design

Induction flowmeters consist of two main parts:

- Flow sensor

- Measuring transducer

Flow sensors are mounted in the pipeline and create electrical voltage with a set of coils.

Measuring transducer calculates generated voltage and converts it into consumption parameters. After that, the received data is transmitted further to the monitoring system.

Working principle

The principle of device operation is based on the Faraday’s law. According to this law, the voltage that is induced in the cross section is directly proportional to the flow velocity.

E=k*B*D*V, where:

E-induced voltage

k - coefficient of proportionality

B- magnetic field strength

V- velocity of the medium in cross section

Hence, knowing the volume in the cross section, it is possible to calculate the flow consumption.

Let’s consider the actions in order of priority. Through the converter, current is going to the coils. They create a magnetic field in the cross section of the pipeline.

Particles in substance flow in this area are divided under the action of such field into negative and positive. Special electrodes are placed on the pipe walls against each other. Magnetic field is located between them and separates general flow into particles.

As a result, a voltage change occurs between the electrodes. Next, the obtained values on the electrodes are transferred to the measuring transducer. It converts them into flow capacity parameters and transmits data to control systems.

Installation Guide

First of all, the device must be installed on the straight sections of the pipeline. This is necessary to reduce the occurrence of turbulence in the flow. The most optimal distance for such placement is the length from 5 to 10 pipe diameters before the sensor and after it.

A great influence on the measurement process has the correct selection of materials inside the pipeline cross-section in measuring areas.

The internal walls are covered with special inserts to improve the durability of a flow meter in operating with aggressive and abrasive medium. Most often, fluoroplastic rubber, enamel and similar protective materials are used to provide such electrical insulation.

A set of coils must be placed opposite each other. Electrodes should also be mounted at the same angle relative to the magnetic field.

Advantages and disadvantages

Like all instrumentation for measuring, flow sensors have their own positive and negative properties.

Advantages of electromagnetic flow meters:

- Minimum hydraulic loss

- Easy operation

- Ability to work with aggressive materials

- Lack of moving mechanical parts

- Wide range of working section diameters

- High accuracy

- Fast response

The lack of hydraulic resistance is due to absence of parts inside the pipe. All its parts are flush with the walls of the pipeline. That’s why, particles from the substance flow do not settle on the walls.

Electromagnetic principle and modern insulation coatings allows working with the most dangerous and abrasive media. The induction flow meter, as well as the pipeline itself, can be cleaned without its dismounting.

The use of the electromagnetic field in the operations eliminates unnecessary mechanical parts, which significantly increases devices work life.

Such sensors can operate in a wide range of cross section diameters. The sensor can work in a wide range of sections with a flow rate from 3 * 10-9 m3/s to 3 m3/s. The same device can work with the sections dimensions that differ in 1000 times.

It should be noted that due to the induction principle, the measurement does not depend on the physical and chemical characteristics of the substance, such as density, viscosity, temperature, and a number of other factors.

Disadvantages of electromagnetic flow meters:

- Particles can effect on results

- Influence of flow turbulence

- Interaction with magnetic particles

- Effect of noise

- The need of electrical insulation

- Interaction with other electromagnetic fields.

- Requirement for electrical conductivity of a substance

The occurrence of bubbles in the flow can affect accuracy of measurements. Turbulence in the cross section is removed by mounting on extended straight sections. For measurement accuracy, it should be avoided irregular velocity in the pipeline.

If the medium has particles with strong magnetization (for example, metal debris) there is a possibility of clogging them in the cross section. Most of all modern systems use a pulsating measurement that avoids such problem.

To ensure the most accurate measurement within the system, it is worthwhile to ensure the insulation of the pipeline from the influence of electromagnetic fields, noises and parasitic currents. The correct selection of lining, pipes and electrodes material solve such problems.

In order to the measurement be performed correctly, the device must be used with substances that have a minimum electrical conductivity threshold of 10-3 S / m (1 S (siemens) = 1-1 Ohm).

Conclusion: Electromagnetic sensors allow to complete use of magnetic induction to perform flow measurements. They can work with the most diverse environments, but it is worthwhile to take care of their proper isolation.

On our site you can find the most popular induction flow meters by Siemens, IFM and many others.