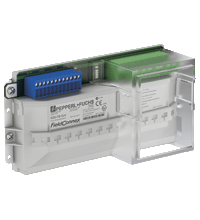

Pepperl+Fuchs FieldConnex Fieldbus Infrastructure

Segment Protector

- High reliability

- Wide range of security features

- Easy installation and configuration

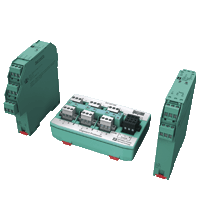

Pepperl+Fuchs Multi-input/output (MIO)

- 12 discrete inputs and outputs

- Aluminum housing with IP66 protection

- Support for FOUNDATION Fieldbus H1

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

Segment Protector

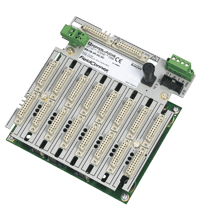

- 8 segments, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 4 segments, redundant, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 8 segments, redundant, individual modules per segment

- Customized for Invensys, FBM228

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Dual, redundant bulk power connections

- Comprehensive diagnostics for the fieldbus physical layer

- Handheld with display and integrated expert system

- Fieldbus interface Ex ia, FISCO, Entity, and DART

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Multi-language support

- Operation in Zone 1/Class I, Div. 1

- Choice of power options for different operating modes

- PC software for enhanced interface and data backup

- Comprehensive diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Automatic setup of diagnostic system

- Full software integration into PCS and PAM possible

- Diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Plug and play - no engineering required

- For online monitoring

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Alarm limits configurable via DIP switches

- Fault indication transmission by voltage free contact

- Output: 21 ... 23 V/500 mA

- Voltage limitation for Entity ic and Ex nL

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- Output: 28 ... 30 V/500 mA

- High-power trunk for high device count and long cable lengths

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- PROFIBUS DP V1 / For 4 segments PA

- Couples PROFIBUS PA devices transparently to PROFIBUS DP

- Optional redundant configuration

- Installation in Zone 2/Class I, Div. 2

- Up to 12 Mbit/s, auto adapting

- For redundant and non-redundant masters

- Supports Flying Redundancy (FR)

- Cyclic/acyclic data exchange

- Gateway PROFINET RT to 4 x PROFIBUS PA segments

- Up to 32 devices per PROFIBUS PA segment

- Installation in Zone 2/Class I, Div. 2

- Ring and system redundancy

- Integrated webserver for diagnostics

- Output: 25 ... 27 V/360 mA

- For most fieldbus applications

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1

- Fixed, high-availability terminator

- No spacing required between modules

- Output: 24 ... 26 V/400 mA

- For extension of fieldbus segments

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Fixed, high-availability terminator

- High efficiency, low heat dissipation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to Entity

- 70 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to FISCO

- 100 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

- Comprehensive diagnostics for the fieldbus physical layer

- Module and motherboard for retrofit of any installation

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Full software integration into PCS and PAM possible

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Common alarm handling

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Alarm handling and integrated I/O for cabinet monitoring/control

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

Complete hardware for connection of FOUNDATION Fieldbus H1 field devices to the host system of your choice

Complete hardware for connection of PROFIBUS PA field devices to a DP-Master

- 4 segments, redundant, individual modules per segment

- Customized for Honeywell, C-Series

- High-power trunk: Live work on devices in any hazardous area

- Optimized for size and quality, low heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Installation in Zone 2/Div. 2

- art. 204715-0011

- Instruments in Zone 0...1/Div. 1

- Short circuit current limitation per output

Segment Protector F2-SP-IC* F2-SP-IC08.1.03.03.00

- Output: 28 ... 30 V/500 mA

- High-power trunk for high device count and long cable lengths

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Highest efficiency, lowest heat dissipation for highest packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

MB FB GTR

- Supply voltage: 18...35 V DC

- Current consumption: max. 2 A

- Output power: max. 120 W (per module)

- Isolation: 250 V AC (power unit/housing)

- Electromagnetic compatibility: EN 61000-6-2, EN 61000-6-3

FieldConnex Fieldbus Infrastructure

FieldConnex is a product line from Pepperl+Fuchs that focuses on providing solutions for fieldbus infrastructure in industrial automation. Fieldbus systems are communication networks used to connect field devices, such as sensors and actuators, to control systems. Below we take a look at FieldConnex Fieldbus Solutions.

Key Components of the FieldConnex Fieldbus Infrastructure

For modern Fieldbuses, Pepperl+Fuchs FieldConnex offers excellent connectivity. With FOUNDATION Fieldbus H1 and PROFIBUS PA, you can easily integrate field devices into your plant. Fieldbus ensures uninterrupted digital data transfer between the plant and the control system and supplies power to all field devices. Let's take a closer look at the solutions from Pepperl+Fuchs.

FOUNDATION Fieldbus H1

FOUNDATION Fieldbus H1 (FF H1) facilitates power and digital data communication linking host systems, such as a DCS or PLC, with field instruments—participants on the same cable exchange status information and control commands. Fieldbus extends beyond process control, enabling remote configuration, asset management, and predictive maintenance.

FieldConnex enables the secure integration of field device data into your DCS. Its straightforward design and dependable components ensure user-friendly operation and durability. With various explosion protection options, this technology is well-suited for installation, commissioning, and providing reliable operation.

PROFIBUS PA

PROFIBUS PA, a widely used PROFIBUS protocol family member, shares identical data formats with PROFIBUS DP. This similarity enables seamless integration of devices into both networks.

Following the IEC 61158-2 standard, PROFIBUS PA is a Fieldbus, facilitating power and digital data transfer between host systems like DCS or PLC and field devices. Digital transmission of status information and control commands occurs between the master and participants linked by the same cable (up to 31 participants). PROFIBUS extends beyond process control, allowing for remote configuration, asset management, and preventive maintenance.

FieldConnex is the ideal system for integrating PROFIBUS PA data into the DP master. Its streamlined design and dependable components ensure simplicity and durability. Incorporating selected explosion protection concepts makes this technology well-suited for installation, commissioning, and providing reliable operation.

Benefits of Implementing FieldConnex in Industrial Automation

Implementing FieldConnex in industrial automation offers several benefits, contributing to the efficiency, reliability, and overall performance of Fieldbus communication networks. Here are some key advantages of FieldConnex Pepperl+Fuchs Automation Products.

Increased reliability

FieldConnex components, such as Fieldbus Segment Protectors and Surge Protectors, enhance the reliability of Fieldbus systems by protecting against short circuits, faults, and voltage surges. This helps prevent network failures and ensures continuous operation.

Advanced diagnostics

The FieldConnex Diagnostic Manager (FDM) provides advanced diagnostic tools for monitoring the health of the Fieldbus network. It allows for proactively identifying issues, reducing downtime, and improving overall system reliability.

Ease of installation and commissioning

FieldConnex components are designed with ease of installation and commissioning in mind. This can lead to quicker deployment times and lower installation costs, as the parts are engineered for compatibility and straightforward integration.

Optimized power distribution

The Fieldbus Power Hub (FPH) optimizes power distribution to field devices, ensuring they receive the required power for reliable operation. This centralized power distribution simplifies wiring and reduces the complexity of the overall system.

Increased network flexibility

FieldConnex supports various fieldbus protocols, providing flexibility in choosing the most suitable communication standard for a particular application. This flexibility allows integration with multiple field devices and control systems.

Extended network reach

Fieldbus Repeaters enable the extension of Fieldbus networks beyond the standard distance limitations. This feature allows for the expansion of the network to cover larger areas without sacrificing communication performance.

Cost savings

By preventing network failures and minimizing downtime through advanced diagnostics and protection mechanisms, FieldConnex helps to reduce maintenance costs and improve overall cost-effectiveness.

Enhanced safety

Surge protectors and other protective components contribute to the safety of the industrial automation system by safeguarding sensitive electronic equipment from electrical surges and other potential hazards.

Scalability

FieldConnex is designed to be scalable, allowing for quickly adding devices and components as the automation system grows. This scalability ensures that the fieldbus infrastructure can adapt to changing operational requirements.

Improved troubleshooting

The diagnostic capabilities provided by FieldConnex components simplify troubleshooting processes. Maintenance personnel can quickly identify and address issues, reducing the time required to return the system to optimal performance.

Advanced Diagnostics with FieldConnex Fieldbus

The Advanced Diagnostic Module (ADM) turns the physical layer of PROFIBUS PA and FOUNDATION fieldbus H1 into a managed asset. ADM in industrial Fieldbus systems automates commissioning and allows online monitoring of the fieldbus segment. It also detects faults in real time. The built-in expert system learns and interprets each element's electrical values and behavior, giving service technicians early, clear warnings. With ADM, Fieldbus management has become much more manageable. Information can be obtained from a secure control room.

Choosing the Right FieldConnex Components for Your Operation

Choosing the right FieldConnex components for your operation involves careful consideration of various factors to ensure compatibility, reliability, and optimal performance. Here are some key steps and factors to consider when selecting the Pepperl+Fuchs FieldConnex installation system.

- Clearly define the requirements of your automation system. Consider factors such as the type of field devices used, the communication protocol required (e.g., PROFIBUS, Foundation Fieldbus), the size of the network, and any specific environmental conditions.

- Ensure that the chosen FieldConnex components are compatible with the Fieldbus protocol

- Used in your application.

- Evaluate the power requirements of your field devices it's essential to choose a power hub that meets the voltage and current requirements of your devices.

- Consider the level of protection provided by FieldConnex components.

- Advanced diagnostics can help in monitoring the health of the network, identifying issues, and facilitating quick troubleshooting.

- Evaluate the Fieldbus topology optimization. FieldConnex components, such as Fieldbus Repeaters, can be used to extend the network reach. Ensure that the chosen components align with the layout and requirements of your specific application.

- FieldConnex components should be easy to integrate into your existing system, and the configuration tools provided should be user-friendly.

- Take into account the environmental conditions of your operation.