Pepperl+Fuchs FieldConnex Fieldbus Infrastructure

- 4 outputs Ex ia IIC

- FieldBarrier in Zone 1/Div. 2

- Instruments in Zone 0...1/Div. 1

- Short circuit current limitation per output

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Power, Com, and Error LEDs

- Supports FISCO and Entity

- Integrated cable tie-downs

Fieldbus Barrier

Fieldbus Barrier

Fieldbus Barrier

Fieldbus Barrier

Fieldbus Barrier

Fieldbus Barrier

- For discrete inputs and outputs

- Aluminum cast iron, IP66

- Configurable cable entries for bus lines and field signal lines

- International approvals

- For FOUNDATION Fieldbus H1

- Installation in Zone 1/Div. 1, intrinsically safe

- Sensors in Zone 0/Div. 1

- Monitors sensor condition

- Removable terminals

- Power, Com, Diagnostics, and Error LEDs

- Test points for easy troubleshooting

- For discrete inputs and outputs

- Aluminum cast iron, IP66

- Configurable cable entries for bus lines and field signal lines

- International approvals

- For PROFIBUS PA

- Installation in Zone 1/Div. 1, intrinsically safe

- Sensors in Zone 0/Div. 1

- Monitors sensor condition

- Removable terminals

- Power, Com, Diagnostics, and Error LEDs

- Test points for easy troubleshooting

- For 8 temperature or analog sensors

- Installation in Zone 1/Div. 1, intrinsically safe

- Sensors in Zone 0/Div. 1

- Connection to fieldbus acc. to FISCO or Entity

- For FOUNDATION Fieldbus H1

- PCS integration via device description and function blocks

- Concentrator method for simplified configuration

- Monitors sensor condition

- For T/C, RTD 2-, 3-, 4-wire, voltage and resistance

- Cold junction compensation

- Removable terminals

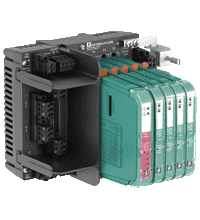

- For 20 analog or 40 digital channels

- Sensors in Zone 0/Div. 1 (depending on module assembly)

- Installation in Zone 2, Div. 2 or safe area

- HART communication via service bus

- For FOUNDATION Fieldbus H1

- Configured via the process control system

- Non-volatile memory for configuration and parameter settings

- Quick communication set-up

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

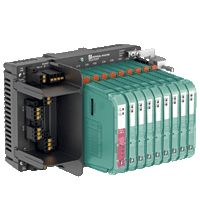

- Basic monitoring for power supply output and health

- Plug-in Module for the FieldConnex Power Hub

- Plug and play - no engineering required

- For online monitoring

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Output: 25 ... 28 V/360 mA

- Universal power supply for most applications

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

System package

System package

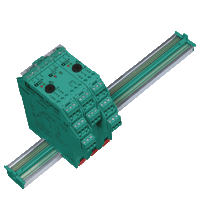

- Series voltage reducing module

- Removable terminals

- Polarity reversal protected

- Installation in cabinet on DIN mounting rail

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Output: 14.7 ... 30.7 V/1 A

- For very high segment load

- High-power trunk for high device count and long cable lengths

- Installation only in safe areas

- For FOUNDATION Fieldbus H1

- Selectable, high-availability terminator

- Low heat dissipation

- Supply via Power Rail

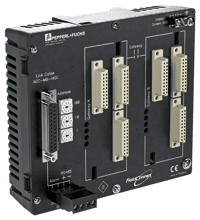

- For 2 gateway modules

- For PROFIBUS PA

- Redundant configuration

- Installation in Zone 2/Class I, Div. 2

- Spring terminals or screw terminals selectable

- 4 segments, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Supports Ex ic voltage limitation

- Installation in Zone 2/Div. 2

- Spring terminals or screw terminals selectable

- 4 segments, simplex, individual modules per segment

- For PROFIBUS PA

- For gateway and power supply modules

- High-power trunk: Live work on devices in any hazardous area

- Optional advanced diagnostics

- Installation in Zone 2/Class I, Div. 2

- Spring terminals or screw terminals selectable

- 4 segments, redundant, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Supports Ex ic voltage limitation

- Installation in Zone 2/Div. 2

- Spring terminals or screw terminals selectable