Pepperl+Fuchs Industrial Sensors

Choose a subcategory:

Show all categories

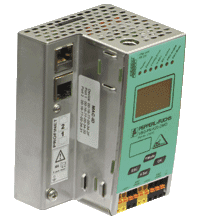

- Connection to PROFINET IO

- Dublicate addressing detection

- Earth fault detection

- AS-Interface noise detection

- Ethernet diagnostic interface

- 2 AS-Interface networks

- Integrated data decoupling

- Integrated webserver

- Integrated switch allows line topology

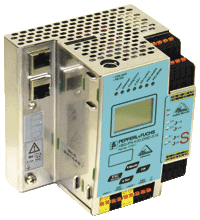

- Connection to PROFINET IO

- Dublicate addressing detection

- Earth fault detection

- AS-Interface noise detection

- 2 AS-Interface networks

- Integrated web server with extended functionality

- Integrated switch allows line topology

- Gateway compliant with AS-Interface specification 3.0

- AS-Interface safety monitor with extended range of functions

- Fulfills technical safety requirements up to SIL 3 / PLe

- Memory card for configuration data

- 2 AS-Interface networks

- 2 safe output relays and 2 safe electronic outputs

- Gateway and safety monitor in one housing

- Connection to PROFINET IO

- SafeLink

- Certified up to SIL 3 according to IEC 61508 and EN 62061 and up to PLe according to EN 13849

- 2 AS-Interface networks

- Six safe electronic outputs

- Integrated data decoupling

- Dublicate addressing detection

- Earth fault detection

- AS-Interface noise detection

- Ethernet diagnostic interface

- Gateway and safety monitor in one housing

- Gateway compliant with AS-Interface specification 3.0

- Connection to PROFINET IO

- AS-Interface safety monitor with extended range of functions

- Certified up to SIL 3 according to IEC 61508 and EN 62061 and up to PLe according to EN 13849

- Memory card for configuration data

- 2 AS-Interface networks

- 2 safe output relays and 2 safe electronic outputs

- PROFIsafe protocol for centralized and secure higher-level control

- Stand alone master with PLC functionality and RS 232 interface

- Large, graphic LCD

- RS 232 diagnosis interface

- Easy commissioning and fault diagnosis via LEDs and graphic display

- Earth fault detection

- AS-Interface noise detection

- Gateway compliant with AS-Interface specification 3.0

- Commissioning, locally on the gateway or via AS-i Control Tools software

- AS-Interface scanner for CompactLogix or MicroLogix 1500 PLC

- Addressing and programming AS-Interface slaves

- Displaying the assigned slave addresses and the status of the inputs

- Setting outputs at the AS-Interface slave

- Also supports profiles S-7.7.A.7 (Spec 3.0), S-0.B and S-7.B (AS Interface Safety at Work)

- The slave connection is short-circuit and overload proof

- Battery charger included with delivery

- Addressing and programming AS-Interface slaves

- Displaying the assigned slave addresses and the status of the inputs

- Setting outputs at the AS-Interface slave

- Also supports profiles S-7.7.A.7 (Spec 3.0), S-0.B and S-7.B (AS Interface Safety at Work)

- The slave connection is short-circuit and overload proof

- Battery charger included with delivery

- Addressing and programming AS-Interface slaves

- Displaying the assigned slave addresses and the status of the inputs

- Setting outputs at the AS-Interface slave

- Also supports profiles S-7.7.A.7 (Spec 3.0), S-0.B and S-7.B (AS Interface Safety at Work)

- The slave connection is short-circuit and overload proof

- Battery charger included with delivery

- Addressing and programming AS-Interface slaves

- Displaying the assigned slave addresses and the status of the inputs

- Setting outputs at the AS-Interface slave

- Also supports profiles S-7.7.A.7 (Spec 3.0), S-0.B and S-7.B (AS Interface Safety at Work)

- The slave connection is short-circuit and overload proof

- Battery charger included with delivery

- Four programming cables included VAZ-PK-1.5M-V1-G, V1S-G-1M-PUR, V1-G-0.3M-PUR-V1-G, and VAZ-PK-FK-0.2M-V1-W

- For use in North and South America

- Addressing and programming AS-Interface slaves

- Displaying the assigned slave addresses and the status of the inputs

- Setting outputs at the AS-Interface slave

- Also supports profiles S-7.7.A.7 (Spec 3.0), S-0.B and S-7.B (AS Interface Safety at Work)

- The slave connection is short-circuit and overload proof

- Additional M12 plug for external power supply for AS-Interface and AUX

- Connecting cable included with delivery

- Battery charger included with delivery

pepperl fuchs vibration sensor

- Protection class: IP67 or IP68

- Vibration resistance: from 0.5 to 10 g

- Sensor diameter: 5 to 15 mm

- Sensor length: 10 to 100 mm

- Mounting: threaded, threaded, flanged, adhesive

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Resolution 1280 x 960 pixel

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

- Comparison of up to 32 height profiles

- Output of X/Z offset

- Intelligent exposure time control

- Laser class 1, eyesafe

- Data Matrix control codes for parameterization

vmt pepperl fuchs

- Processing speed: Process images at high speed, allowing them to be used to automate complex tasks.

- Reliability: designed and manufactured using the most advanced technologies

- Energy saving: designed with energy conservation in mind, allowing them to operate smoothly for long periods of time.

- Web interface for easy access to video files and live streams

- Video ring buffer with a pre-run buffer for automatic recording of video up to 60 seconds before and after a situation that requires fault analysis or documentation

- Trigger video/image capture via UDP, REST API, or a digital hardware input for easy integration

- Find situations of interest quickly due to timestamped events

- REST API for full HMI integration of all camera functions

- Wide range of detection tools for flexible inspection tasks

- Combinable vision tools for feature detection, completeness checking, code reading, text recognition and object position checking

- 32 Jobs on-board can be saved

- Integrated illumination

- Mechanical focus adjustment

- Easy integration with flexible programmable data output